Split fabricated type centering bracket for anchor rod and anchor rod

A centering bracket and prefabricated technology, applied in construction, sheet pile wall, infrastructure engineering and other directions, can solve the problems of cumbersome centering method, troublesome construction, insufficient bearing capacity of the interface between the bolt body and the grouting body, etc. The construction efficiency is improved, the installation is convenient, and the contact pressure is small.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0104] refer to Figure 1 to Figure 17 , an assembled guide cap for anchor rods, including an anchor rod body 10, a plug body 20 sleeved on the anchor rod body 10, a stopper 40 and a locking ring 50 for fixing the plug body 20, and a snap Connected to the guide cap 30 on the plug body 20. The anchor rod body 10 involved in the present invention can be a steel bar or a steel strand. The upper ring of the plug body 20 is provided with a plug groove 23 and a plug mouth 24. The axial end of the body 20 extends to the other end, and the plug groove 23, the plug mouth 24 and the grouting pipe drag groove 27 extend from the outer wall of the plug body 20 to the center; the upper ring of the plug body 20 is provided with a T-shaped slot 25. The T-shaped slot 25 extends from one axial end of the plug body 20 to the other end, and the T-shaped slot 25 extends from the outer wall of the plug body 20 to the center; Slot 26. The limit grooves 26 at both ends of the plug body 20 are sym...

Embodiment 2

[0110] refer to Figures 18 to 29 , the present invention also proposes a combined pressure bearing plate capable of strengthening the front and rear grouting bodies, including a pressure bearing plate 60, a central hole 21 and a rib hole 22 are arranged on the pressure bearing plate, and there are multiple rib holes 22, many A rib hole 22 ring is located on the periphery of the central hole 21. The present invention also includes a tube joint hole 61 arranged on the pressure bearing plate 60, a double-ended screw joint 71 is pierced in the tube joint hole 61, and the two ends of the double-ended screw joint 71 along the axial direction are set as the first end and the first end. The second end, the first end is screwed with a pressure-bearing section pipe joint 72, and the second end is screwed with a tension section pipe joint 73, and the pressure-bearing section pipe joint 72 and the tension section pipe joint 73 are respectively arranged on the pressure-bearing section. O...

Embodiment 3

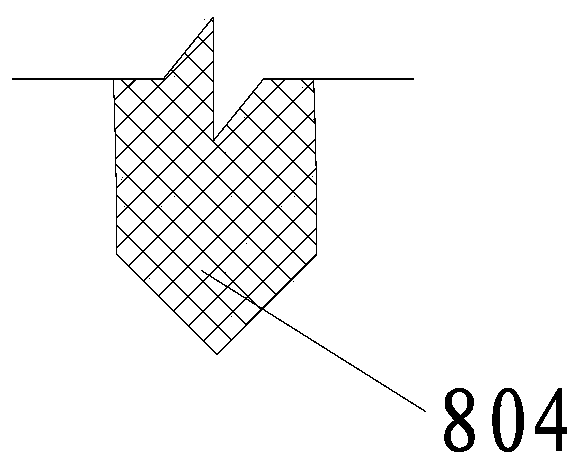

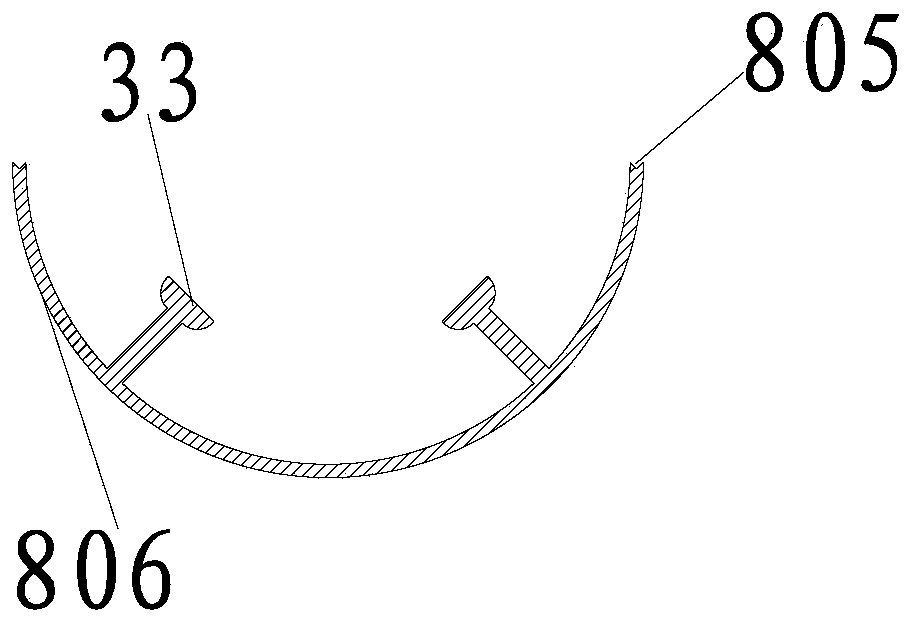

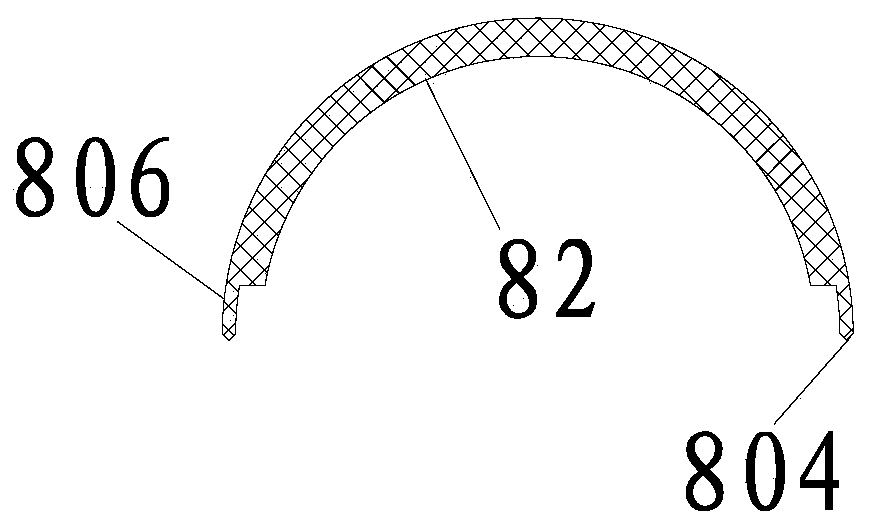

[0118] refer to Figure 3 to Figure 12 , Figures 30 to 38 , the present invention also proposes a split-type centering plug for bolt centering, including a plug body 20, the plug body 20 is provided with a limit mechanism on both sides in the axial direction, and the plug body 20 is provided with a rib mouth 24 and a The plug groove 23 also includes two semi-cylindrical brackets 80, the inner wall of the brackets 80 is provided with a T-shaped rail 33, and the plug body 20 is correspondingly provided with a T-shaped rail that matches the T-shaped rail 33. A slot 25, a T-shaped slot 25 extends from one axial end of the plug body 20 to the other end, a T-shaped slot 25 extends from the outer wall of the plug body 20 to the center, and one end of the bracket 80 in the axial direction is provided There is a guide plate 81 , and a limiting member is provided on the inner wall of the bracket 80 to limit the movement of the plug body 20 to the guide plate 81 .

[0119] As a prefer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com