Dry method integral paving structure and method for fabricated ground

A prefabricated, floor decoration technology, which is applied to floors, building structures, partial raised floors, etc., can solve the problems of many processes, easy to appear messy, protracted construction period, etc., to simplify procedures and eliminate formaldehyde pollution , the effect of shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

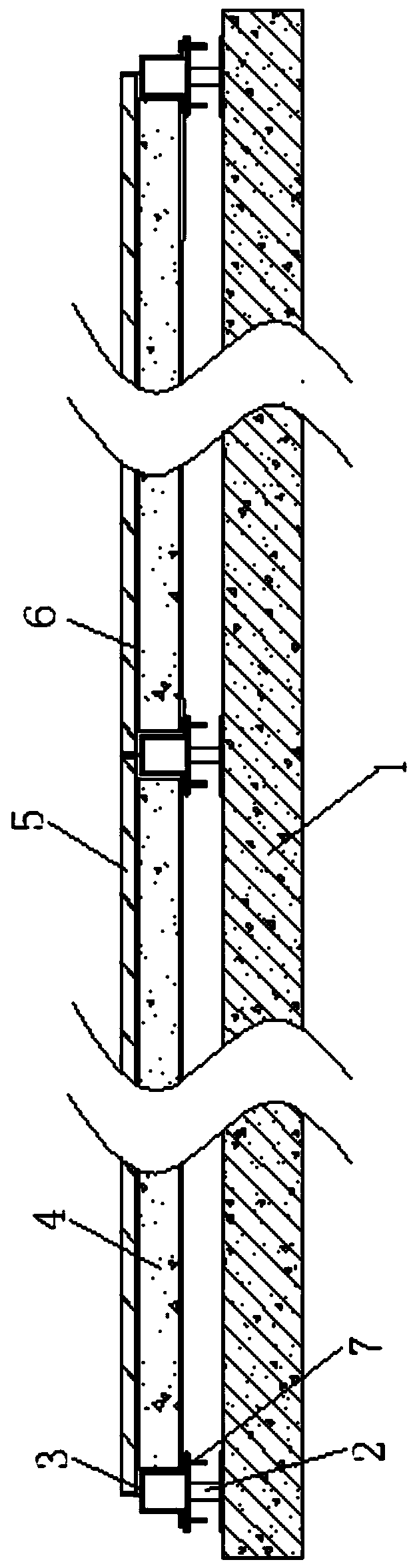

[0042] see figure 1 , the figure shows a prefabricated ground dry overall pavement structure provided by Embodiment 1 of the present invention, which includes a ground base 1; a leveling load-bearing assembly, which includes a plurality of support bases 2 and is arranged The bearing frame 3 on the upper surface, the support base 2 is arranged on the ground base 1, and the support base 2 is fixedly connected with the ground base 1; The top surface; the leveling load-bearing components are arranged in multiple groups; the base decoration layer 4 is arranged on the bearing frame 3; the ground decoration layer 5 is laid on the base decoration layer 4.

[0043] The dry method overall pavement structure of the prefabricated ground provided in this embodiment mainly includes a ground base 1, a leveling load-bearing component, a base decoration layer 4 and a ground decoration layer 5, and the leveling load-bearing component includes a plurality of support seats 2 and the bearing fram...

Embodiment 2

[0051] see figure 1 , the figure shows a prefabricated ground dry overall pavement structure provided by Embodiment 2 of the present invention. This embodiment further makes the following technical solutions as improvements on the basis of the above-mentioned embodiments: An adhesive layer 6 is arranged between the base decorative layer 4 and the ground decorative layer 5, and the adhesive layer 6 is an adhesive; the base decorative layer 4 is a cement board, and the ground decorative layer 5 is a tile or a floor. Through the setting of the above structure, the decorative layer can be quickly paved, the decoration efficiency is improved, and the construction period is greatly shortened.

Embodiment 3

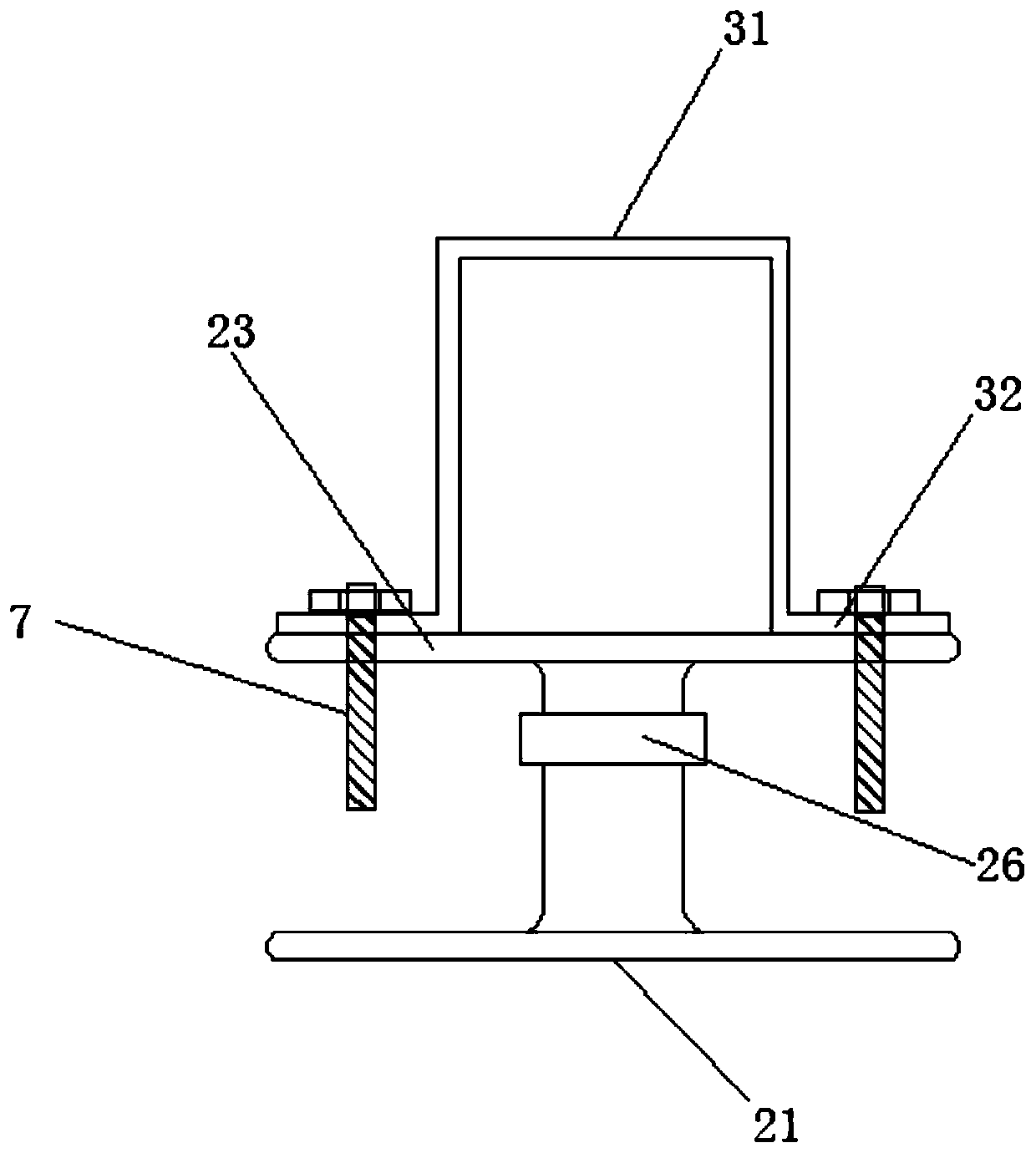

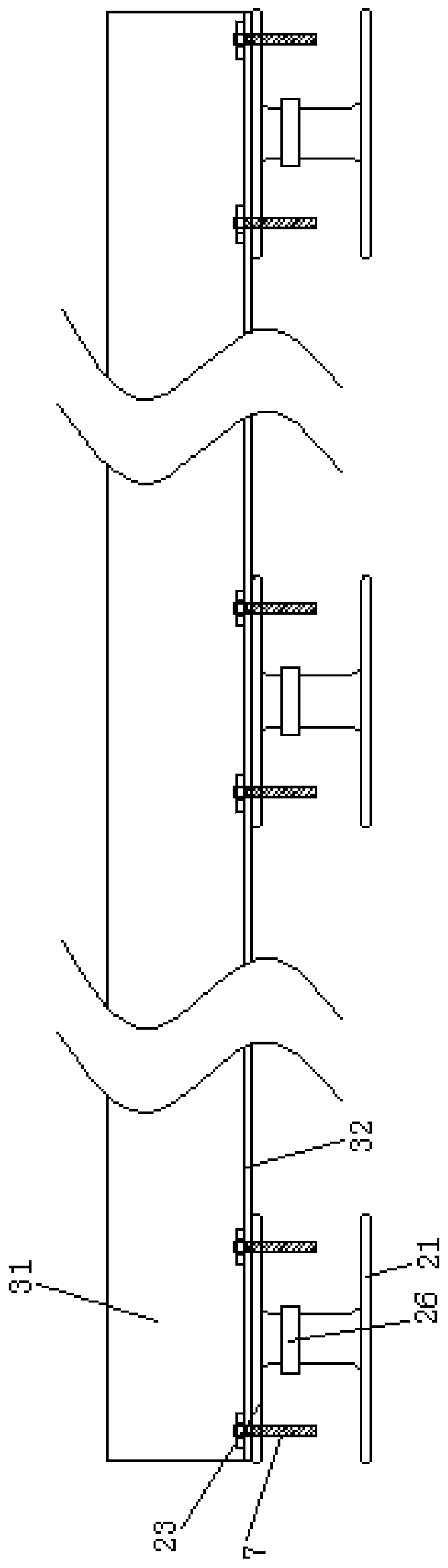

[0053] see Figure 2 to Figure 5 , the figure shows a prefabricated ground dry overall pavement structure provided by Embodiment 3 of the present invention. This embodiment further makes the following technical solutions as improvements on the basis of the above-mentioned embodiments: The support base 2 includes a base, a support frame and an adjustment member 26, the base is provided with a bottom plate 21 and a first connecting rod 22, the support frame is provided with a support plate 23 and a second connecting rod 24; the first connecting rod 22 is provided with a connecting hole 25, the second connecting rod 24 is threadedly connected to the connecting hole 25; the adjusting member 26 is sheathed on the second connecting rod 24 and the two are threaded; wherein, the adjusting member 26 is a nut, and the adjustment is more convenient. Through the setting of the above structure, the support base 2 is used to support the bearing frame 3, and the bearing frame 3 can carry all...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com