Composite adhesive for timber, formaldehyde-free shaving board and manufacturing method of formaldehyde-free shaving board

A composite adhesive and aldehyde adhesive technology, which is applied in wood processing appliances, applications, household components, etc., can solve the problems of slow thermal curing efficiency, high adhesive prices, instability and other problems, and can solve production problems. High cost, good market prospects and good water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

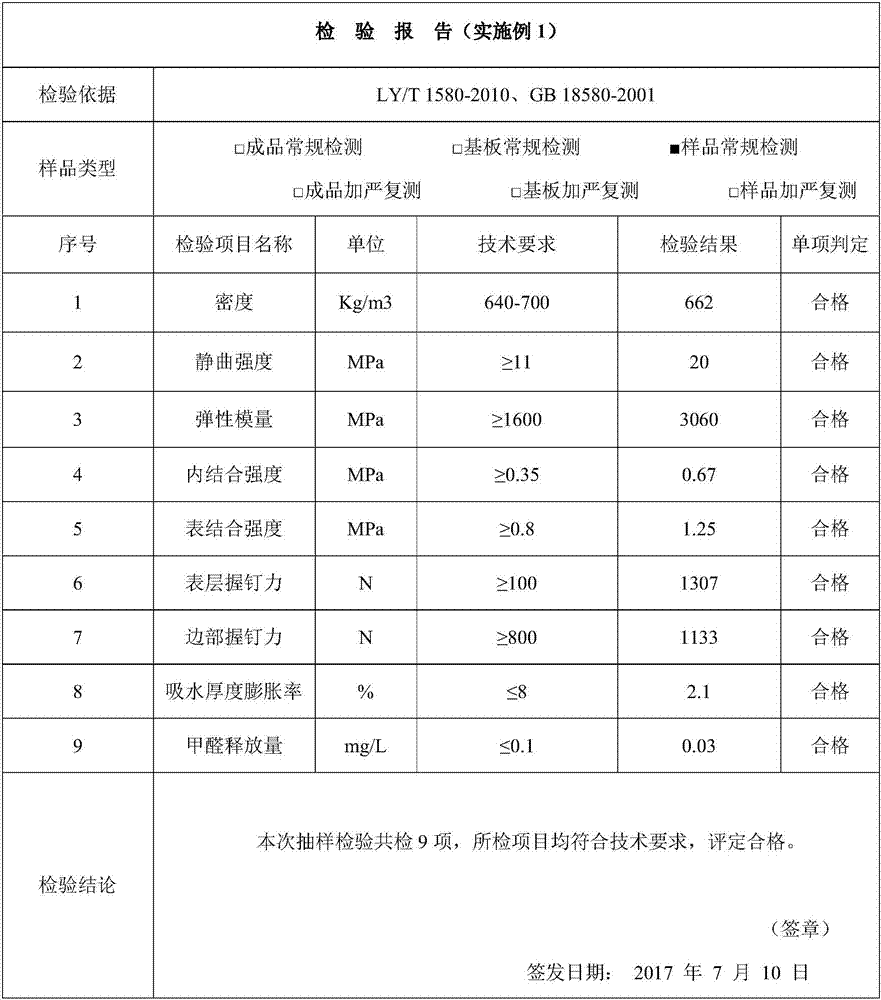

Embodiment 1

[0025] Compound Adhesive

[0026] Bio-based formaldehyde-free adhesive (absolutely dry absorbing aldehyde king ECCA) 7g, aromatic isocyanate (M20S) 4g;

[0027] Production method of zero-aldehyde particleboard

[0028] Surface layer: Dry 100g of shavings to a moisture content of 1%, apply 15g of bio-based formaldehyde-free adhesive (ECCA) through a glue mixer, and add 0.8g of liquid waterproofing agent (emulsified paraffin);

[0029] Core layer: Dry 100g of shavings to a moisture content of 1%, apply 7g of bio-based formaldehyde-free adhesive (ECCA), 4g of aromatic isocyanate (M20S), and 0.4g of waterproofing agent (melted paraffin) through a glue mixer, Paving and pre-pressing, hot-pressing under the conditions of temperature 240 degrees, pressure 3.5MPa, hot-pressing factor 5s / mm (continuous press) to obtain a particleboard with a thickness of 18mm.

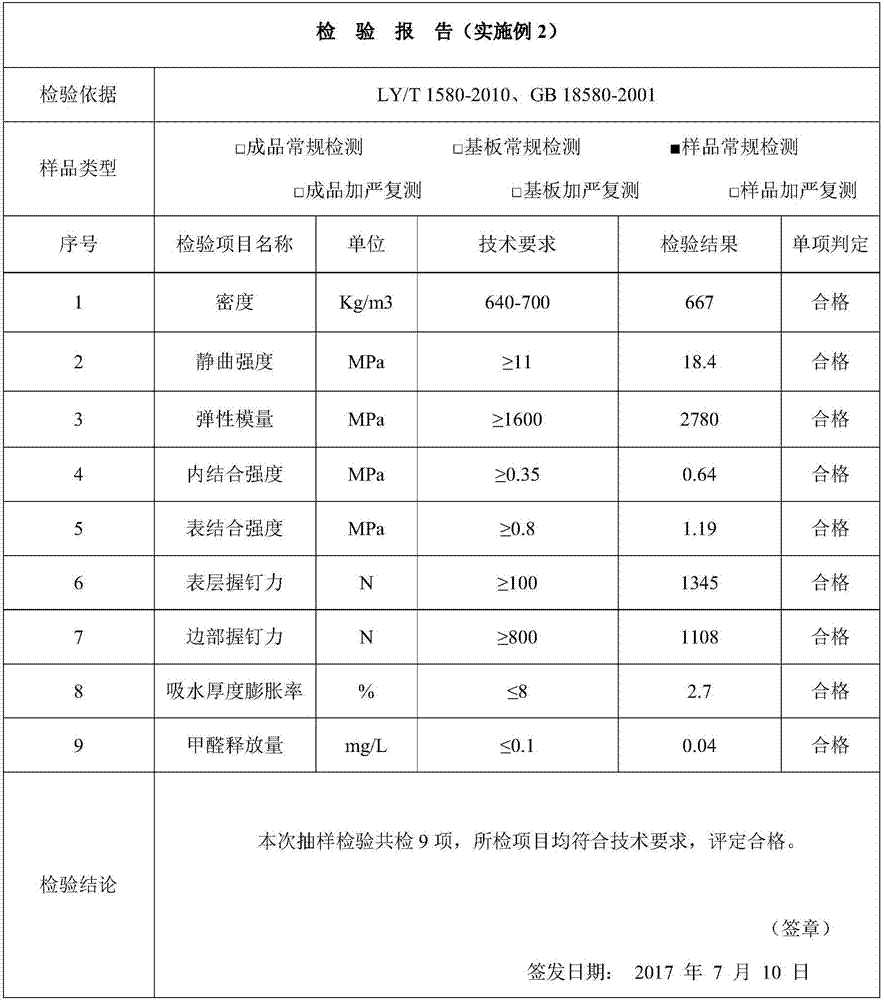

Embodiment 2

[0031] Compound Adhesive

[0032] Bio-based formaldehyde-free adhesive (FLABO) 6g, isocyanate (WBP) 3g;

[0033] Production method of zero-aldehyde particleboard

[0034] Surface layer: Dry 100g of shavings to a moisture content of 1.5%, apply 13g of bio-based formaldehyde-free adhesive (FLABO) and 1g of liquid waterproofing agent (emulsified paraffin) through a glue mixer;

[0035] Core layer: Dry 100g of shavings to a moisture content of 1.5%, apply 6g of bio-based formaldehyde-free adhesive (FLABO), 3g of aromatic isocyanate (WBP), and 0.5g of water repellent (emulsified paraffin) through a glue mixer, Paving and pre-pressing, hot-pressing under the conditions of temperature 235 degrees, pressure 3.8MPa, hot-pressing factor 6s / mm (continuous press) to obtain a particleboard with a thickness of 18mm.

Embodiment 3

[0037] Compound Adhesive

[0038] Bio-based formaldehyde-free adhesive (absolute dry soybean protein adhesive) 5g, isocyanate (M20R) 2g;

[0039] Production method of zero-aldehyde particleboard

[0040] Surface layer: Dry 100g of shavings to a moisture content of 2%, apply 10g of bio-based formaldehyde-free adhesive (ECCA) and 1.2g of liquid waterproofing agent (emulsified paraffin) through a glue mixer;

[0041] Core layer: Dry 100g of shavings to a moisture content of 2%, apply 5g of bio-based formaldehyde-free adhesive (soybean protein adhesive), 2g of aromatic isocyanate (M20R), and 0.6g of waterproofing agent (emulsified paraffin) through a glue mixer , Paving pre-pressing molding, hot pressing under the conditions of temperature 230 degrees, pressure 4MPa, hot pressing factor 7s / mm (continuous press) to obtain a particleboard with a thickness of 18mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com