Flow turbulence paraffin cutting screw rod device for rod pump well

A technology of scraping wax and screw, which is applied in the direction of isolation device, production fluid, wellbore/well parts, etc., which can solve the problems of high cost and high labor intensity, and achieve the effect of not easy crystallization, improving lifting capacity and increasing flow rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

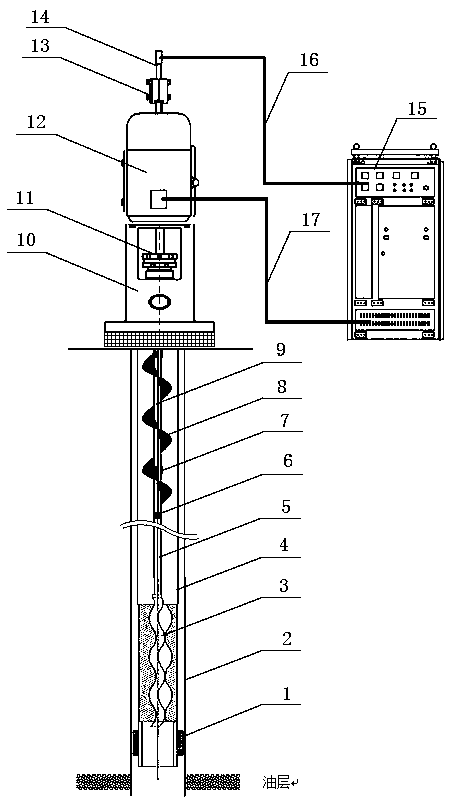

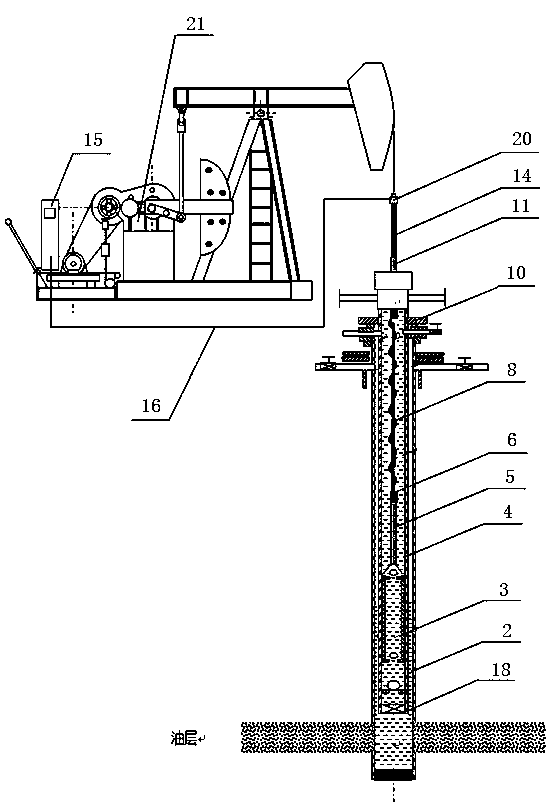

[0027] Below in conjunction with accompanying drawing, the present invention will be further described:

[0028] This spoiler wax-scraping screw device for rod pump wells includes a plug 6, a spoiler wax-scraper screw 8, a heating cable 9, a hollow polished rod 14, and a power supply control cabinet 15. The spoiler wax-scraper screw 8 is arranged on the oil pipe 4 Inside, the lower end of the spoiler wax scraping screw 8 is threadedly connected with the plug 6, and the plug 6 is connected with the sucker rod 5, and the upper end of the spoiler wax scraper screw 8 is threaded with the centralizing collar 7, and the centralizing collar 7 is connected with the hollow polished rod 14; Wax-scraping screw 8 is formed by connecting sections of hollow screws through centralizing collars 7, which are connected in turn according to the required length. After reaching the wellhead, centralizing collars 7 are connected with hollow polished rods 14. The cable 9 is lowered from the hollow p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com