An oilfield-specific quantum wax scale treatment integrated device

A quantum, wax scale technology, applied in vibration generating devices, wellbore/well components, earthwork drilling, etc., can solve the problems of affecting the wax scale removal effect, non-existence, insufficient sonic vibration energy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

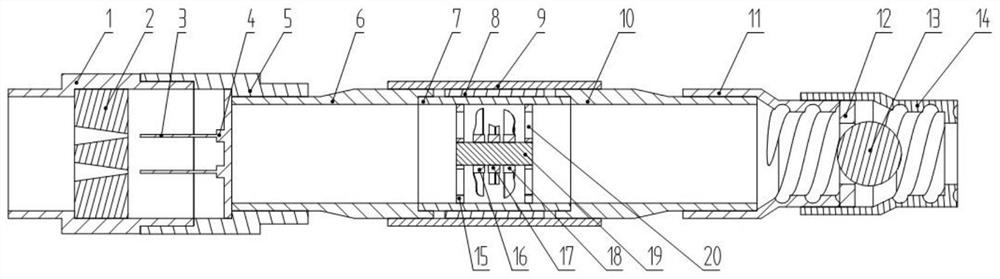

[0034] Embodiment 1, with reference to Figure 1-8 , the present invention is an oilfield-specific quantum wax scale treatment integrated device, comprising a jet vibration assembly, a quantum cavitation assembly fixedly connected to the right side of the jet vibration assembly, a vortex jet assembly fixedly connected to the right side of the quantum cavitation assembly, and a quantum cavitation assembly fixedly connected to the right side of the quantum cavitation assembly. The cavitation component is fixedly connected with a return flow mixed-phase component;

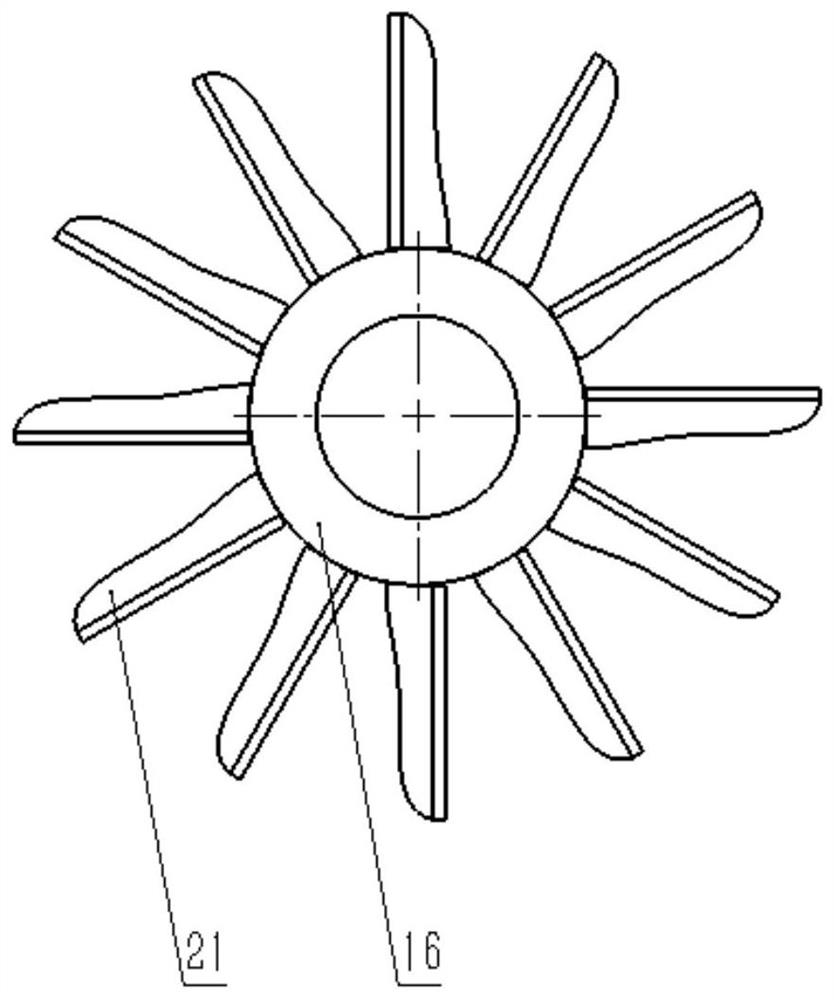

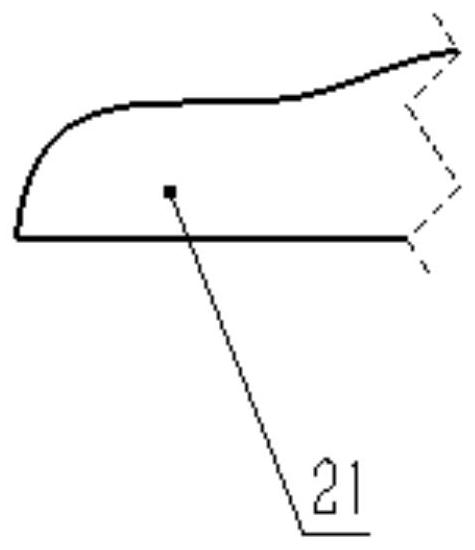

[0035]The backflow mixed-phase component includes a fixed shaft 19, the two ends of the fixed shaft 19 are respectively fixedly connected with the first fixed frame 15 and the second fixed frame 20, and the middle part of the fixed shaft 19 is sequentially connected with the first deflector 16, the second deflector 17 and third deflector 18;

[0036] The first fixing frame 15 and the second fixing frame 20 are fixedl...

Embodiment 2

[0046] Embodiment 2, with reference to Figure 9 As shown, the difference between this embodiment and Embodiment 1 is that the inner wall of the first variable buckle joint 6 is fixedly connected with a backstop ring 24 , and the left side of the backstop ring 24 is equipped with a guide ball 25 . When the pumping unit is started, the oil pressure in the oil pipeline is relatively small. As the start-up time prolongs, the oil pressure in the pipeline gradually increases. The oil between the phase-mixing components is squeezed and moves to the side of the return flow mixing-phase component, pushing the first deflector, the second deflector and the third deflector to rotate. As the pressure in the pipeline further increases, the deflector ball 25 is against the end of the fixed shaft 19, and the oil passes through the gap between the deflector ball 25 and the first variable buckle joint 6. Compared with the solution in Embodiment 1, The oil flow rate of the impingement reflux m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com