Detection method and detection system for upstream pressure of Venturi tube

A venturi tube and detection method technology, applied in the direction of charging system, fuel injection control, exhaust gas recirculation, etc., can solve the problems of no longer updating, affecting the use of EGR, etc., to improve accuracy, ensure effectiveness and accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

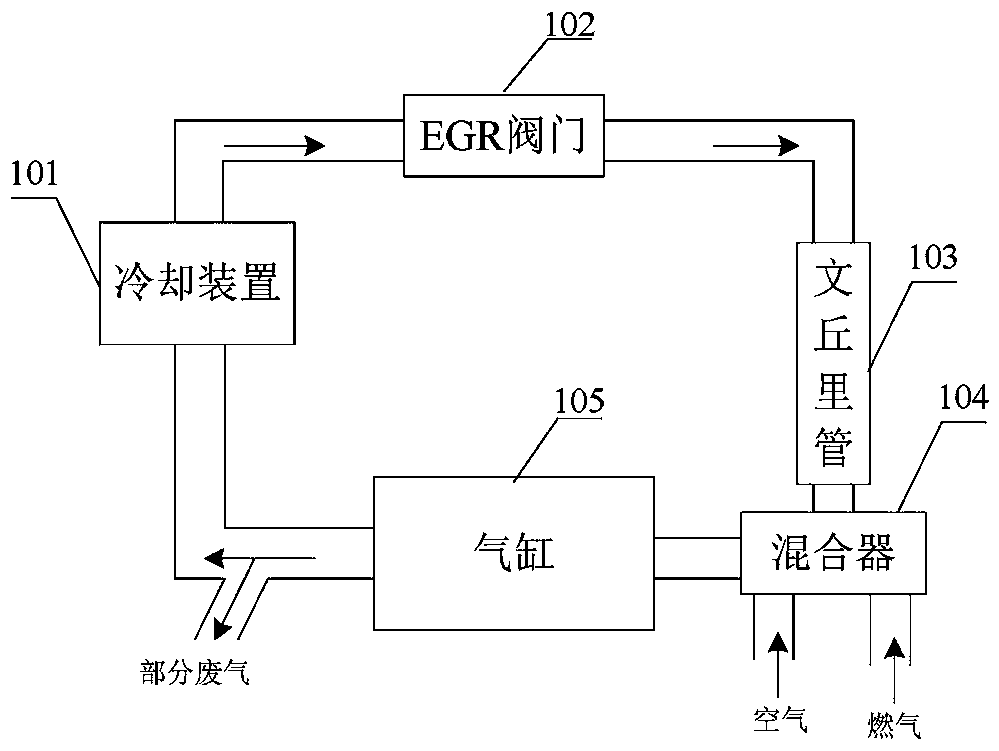

[0032] Embodiment 1 of the present application provides a method for detecting upstream pressure of a Venturi tube, which is applied to an exhaust gas recirculation system (hereinafter referred to as EGR) equipped with a Venturi tube, and will be described in detail below with reference to the accompanying drawings.

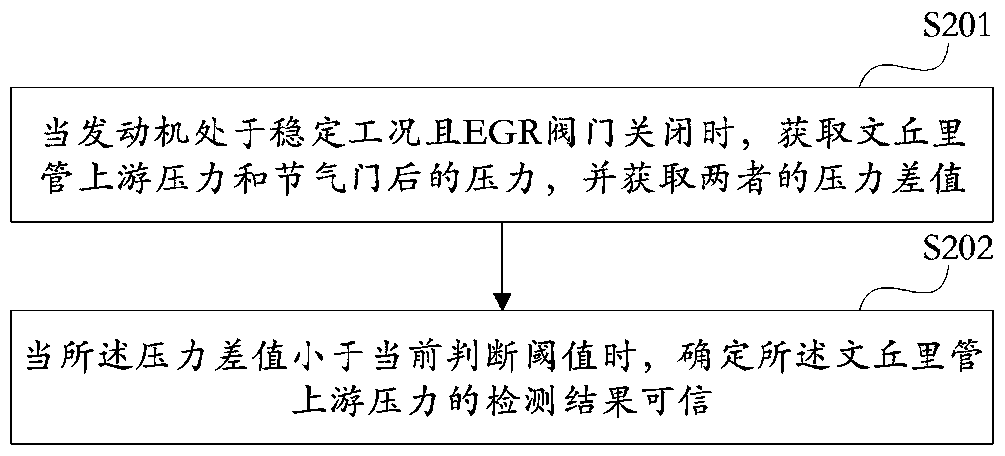

[0033] see figure 2 , which is a flowchart of a method for detecting upstream pressure of a Venturi tube provided in Embodiment 1 of the present application.

[0034] The method described in the embodiment of the present application includes the following steps:

[0035] S201: When the engine is in a stable working condition and the EGR valve is closed, obtain the upstream pressure of the Venturi tube and the pressure after the throttle valve, and obtain the pressure difference between them.

[0036] When the EGR valve is closed, there is no exhaust gas flow in the Venturi tube, and the Venturi tube is directly connected to the intake pipe of the engine. When t...

Embodiment 2

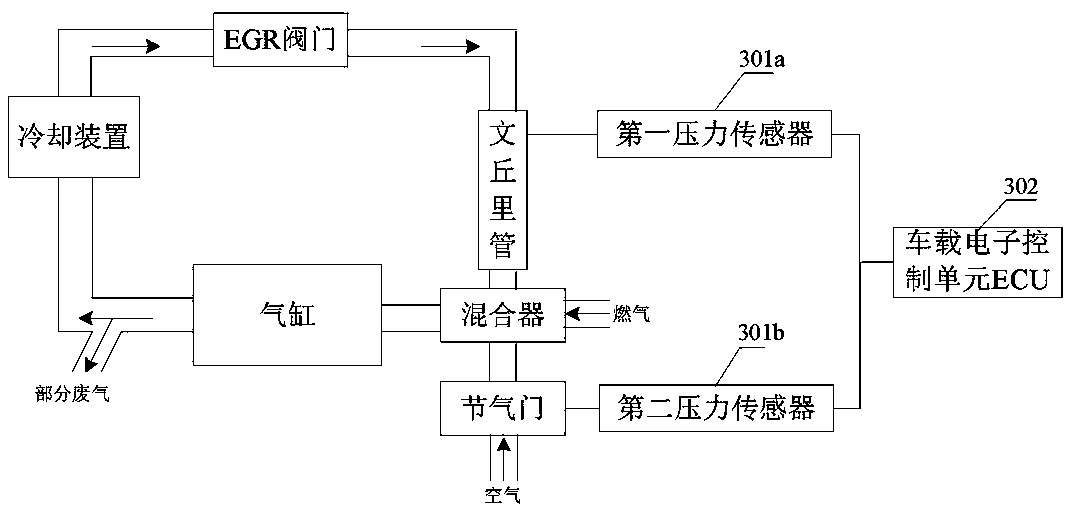

[0051] Based on the method for detecting the pressure upstream of the Venturi tube provided in the above embodiments, Embodiment 2 of the present application also provides a system for detecting the pressure upstream of the Venturi tube, which will be described in detail below with reference to the accompanying drawings.

[0052] see image 3 , which is a schematic diagram of a pressure detection system upstream of the Venturi tube provided in Embodiment 2 of the present application.

[0053] The system described in the embodiment of the present application includes: a first pressure sensor 301a, a second pressure sensor 301b, and a vehicle-mounted electronic control unit ECU302. The "first" and "second" are just for convenience of description, and do not constitute a limitation on the two pressure sensors.

[0054] The vehicle-mounted electronic control unit ECU302 is used to control the first pressure sensor 301a to detect the upstream pressure of the Venturi tube and contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com