Composite phase change heat exchanging MGGH and waste heat recycling system

A composite phase-change heat and heat exchanger technology, which is applied in the field of environmental engineering, can solve the problems of limited cooling range and flue gas waste heat that cannot meet the temperature rise, and achieve the goal of preventing low-temperature corrosion, realizing deep waste heat recovery, and effective wall temperature. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

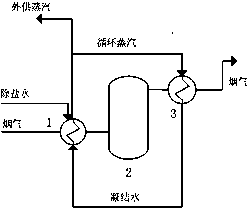

[0013] As shown in the accompanying drawings, a MGGH and waste heat recovery system with composite phase-change heat is composed of 1. a heat exchanger in the evaporation section, 2. a desulfurization tower, and 3. a heat exchanger in the condensation section; when the system is running, the high-temperature flue gas After passing through the heat exchanger 1 of the evaporation section, it enters the desulfurization tower 2, and after passing through the heat exchanger 3 of the condensation section, it is discharged into the atmosphere. The heat exchanger 1 in the evaporating section absorbs the heat of the flue gas to generate steam, which is naturally transferred to the heat exchanger 3 in the condensing section through the density difference, and heat is released in the condensing heat exchanger 3 to heat the flue gas, and the steam turns into condensed water and returns to the evaporating section The heat exchanger absorbs heat again, forming a closed cycle. When the tail ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com