A thermal power plant boiler exhaust heat recovery system

A waste heat recovery system and boiler technology, applied in preheating, feed water heaters, indirect heat exchangers, etc., can solve problems such as thermal power plant boiler exhaust heat loss, improve safety, reduce heat transfer temperature difference, improve The effect of the heat transfer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

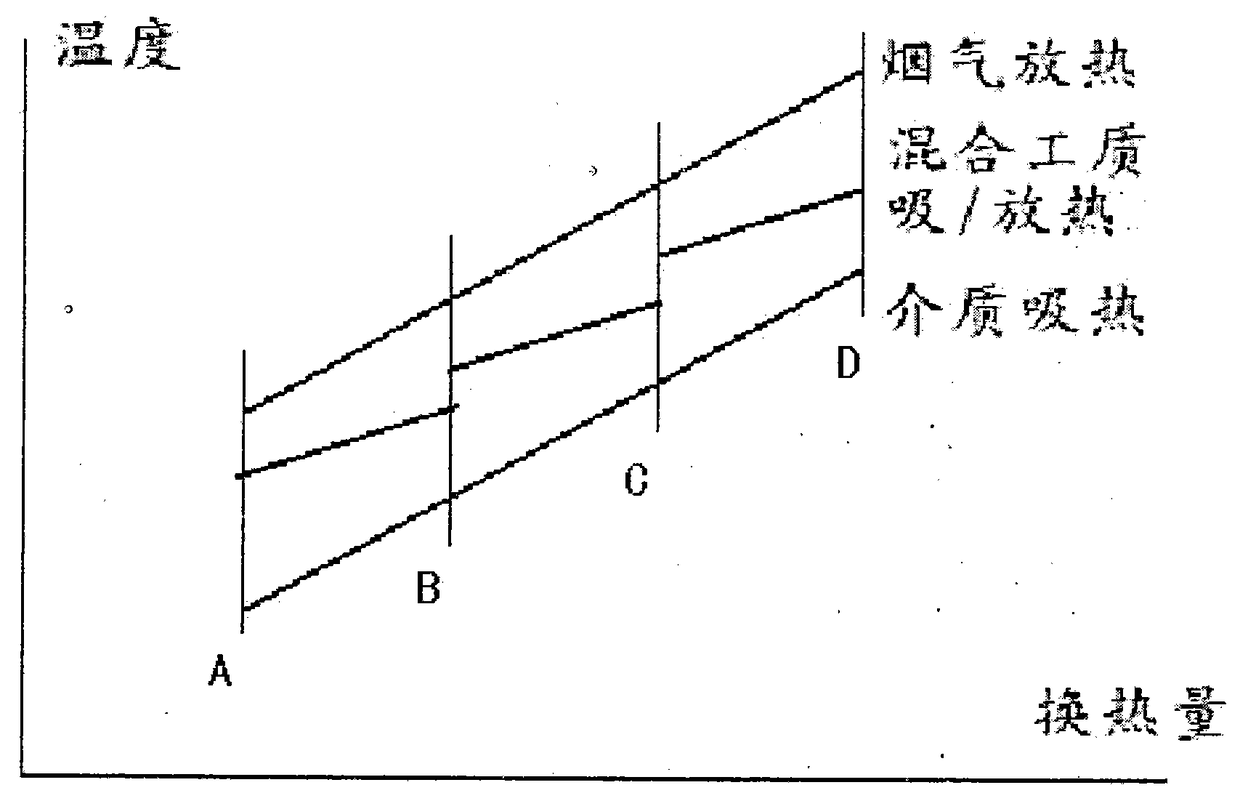

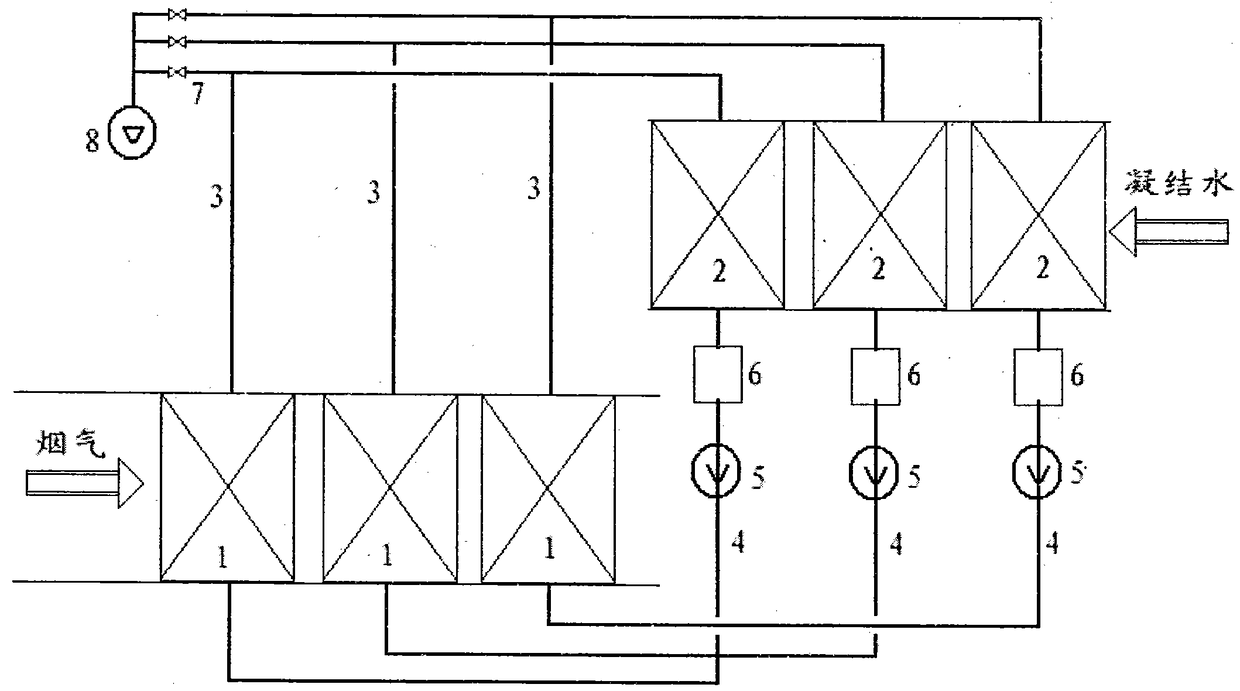

[0012] The heat pipe is a high-efficiency heat transfer element, which has the advantages of high heat transfer coefficient and large heat transfer amount; however, in the conventional capillary heat pipe heat exchanger, each heat pipe is used as a heat exchange unit, and the heat-absorbing section and the heat-dissipating section need to be nearby. The layout affects the flexibility of its system design; the conventional single-group separate heat pipe integrates the heat-absorbing section and the heat-radiating section, and only provides a set of heat exchangers with the same working conditions. The heat exchange temperature difference between the water sides cannot be further reduced, which affects the thermal economy; the gravity heat pipe needs to arrange the heat release section on the upper part of the heat absorption section, which affects the adaptability of the system; the heat pipe heat exchanger uses a single working medium, so that The heat transfer temperature dif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com