High temperature and high pressure coal rock supercritical carbon dioxide fracturing-creep deformation-seepage experimental method

A carbon dioxide, high temperature and high pressure technology, applied in permeability/surface area analysis, measurement device, suspension and porous material analysis, etc., can solve problems such as difficult gas permeability, difficult, difficult to overcome permeability and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

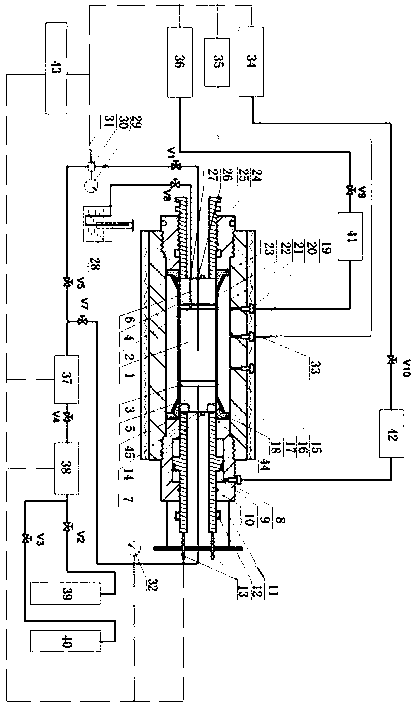

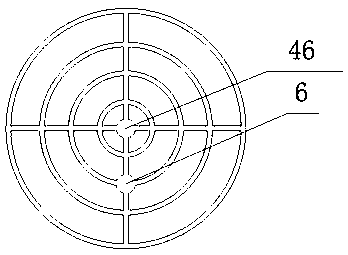

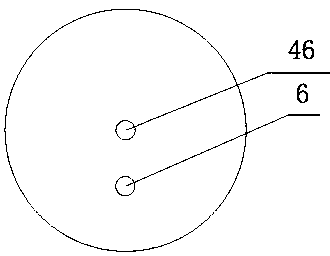

[0056] Implementation method: Coal rock supercritical carbon dioxide fracturing-creep-seepage test device under high temperature and high pressure, which is characterized in that the device can load high stress and high temperature conditions on coal rock samples, and the size of coal rock samples can be Ф50×100mm , the axial pressure and confining pressure of the coal rock sample can reach 70MPa, and the temperature of the coal rock sample can reach 300°C, which can simulate the geological environment where the mineral burial depth reaches 2500m.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com