Composite sleeper pore defect identification method based on Gabor multi-feature extraction and optimization

A composite sleeper and defect recognition technology, applied in character and pattern recognition, image data processing, instruments, etc., can solve problems such as quantitative defect recognition, and achieve the effect of improving recognition accuracy and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

[0043] In order to make the above objects, features and advantages of the present invention more obvious and understandable, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments:

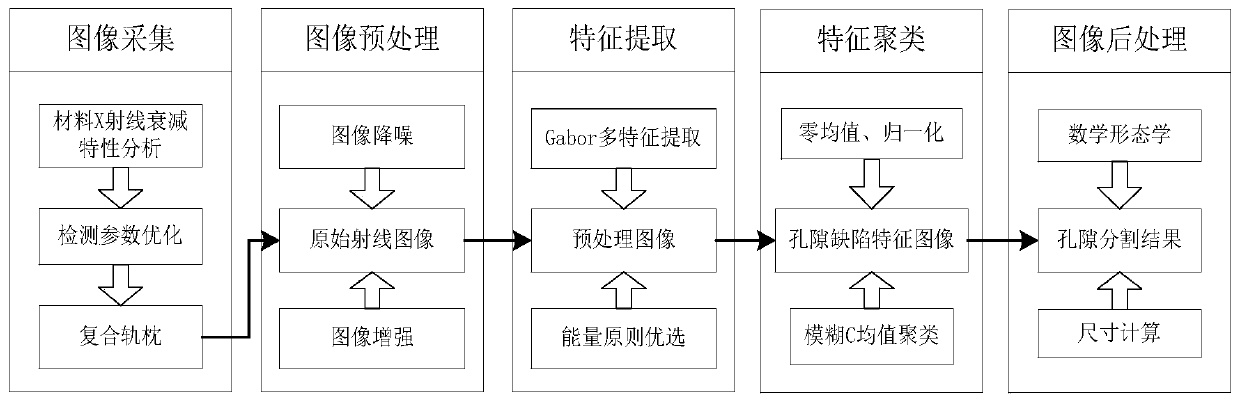

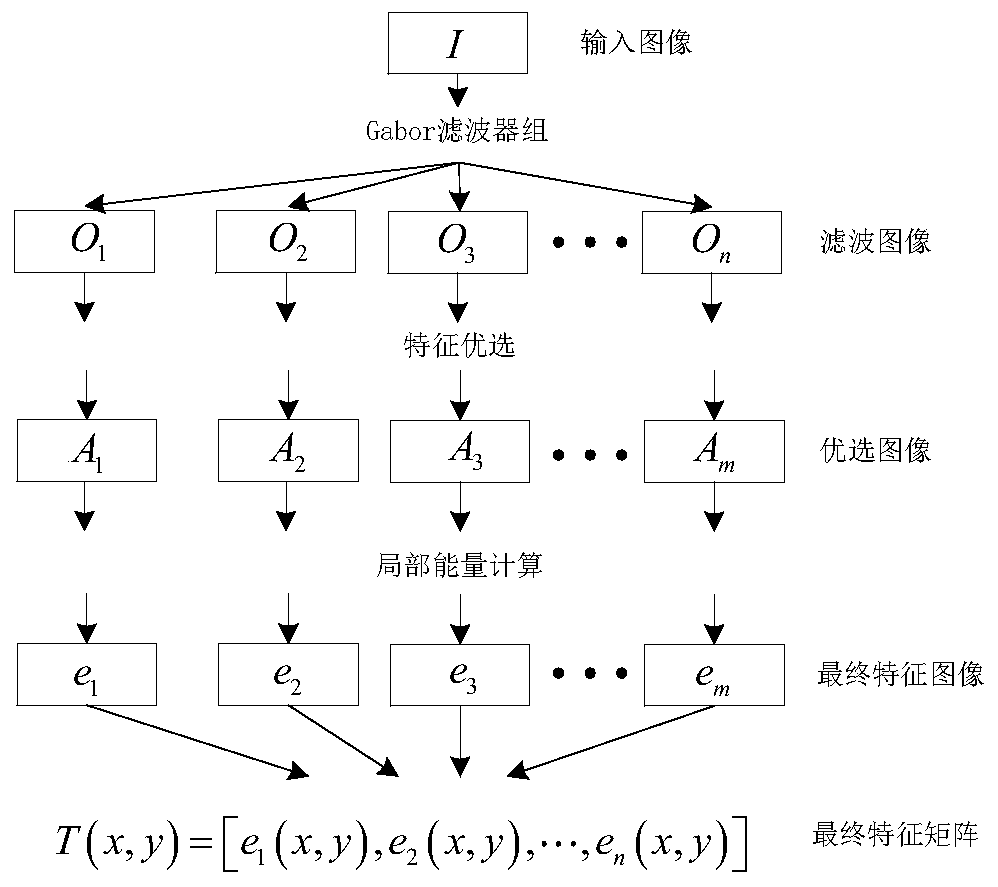

[0044] refer to figure 1 Shown is the flow chart of composite sleeper pore defect identification. First, based on the X-ray attenuation characteristics of the composite sleeper, the X-ray transillumination detection is performed on the composite sleeper with the optimal detection system parameters to obtain the original ray image; then, the original ray image is obtained. The image is preprocessed, including line minimum noise reduction and blur enhancement; then, the multi-scale and multi-directional feature extraction of the ray image is performed using the designed Gabor filter bank, and the image wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com