Vacuumizing and liquid injection device

A liquid injection and vacuum technology, applied in the direction of secondary battery gas removal, electrical components, circuits, etc., can solve the problems of low vacuum efficiency, time-consuming, high time cost, etc., to ensure sealing, ensure position accuracy and Stability, quality-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments and accompanying drawings, and the contents mentioned in the embodiments are not intended to limit the present invention.

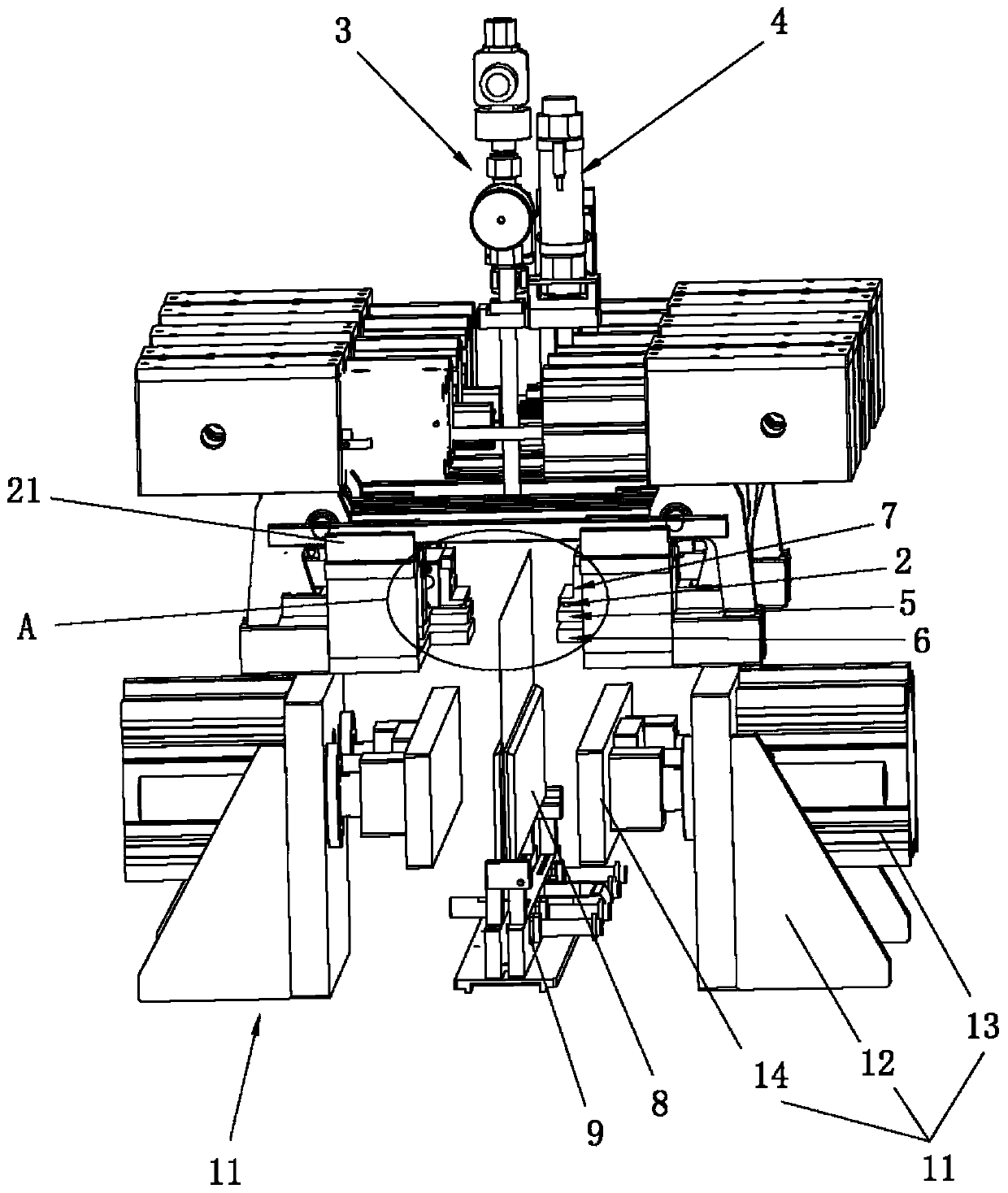

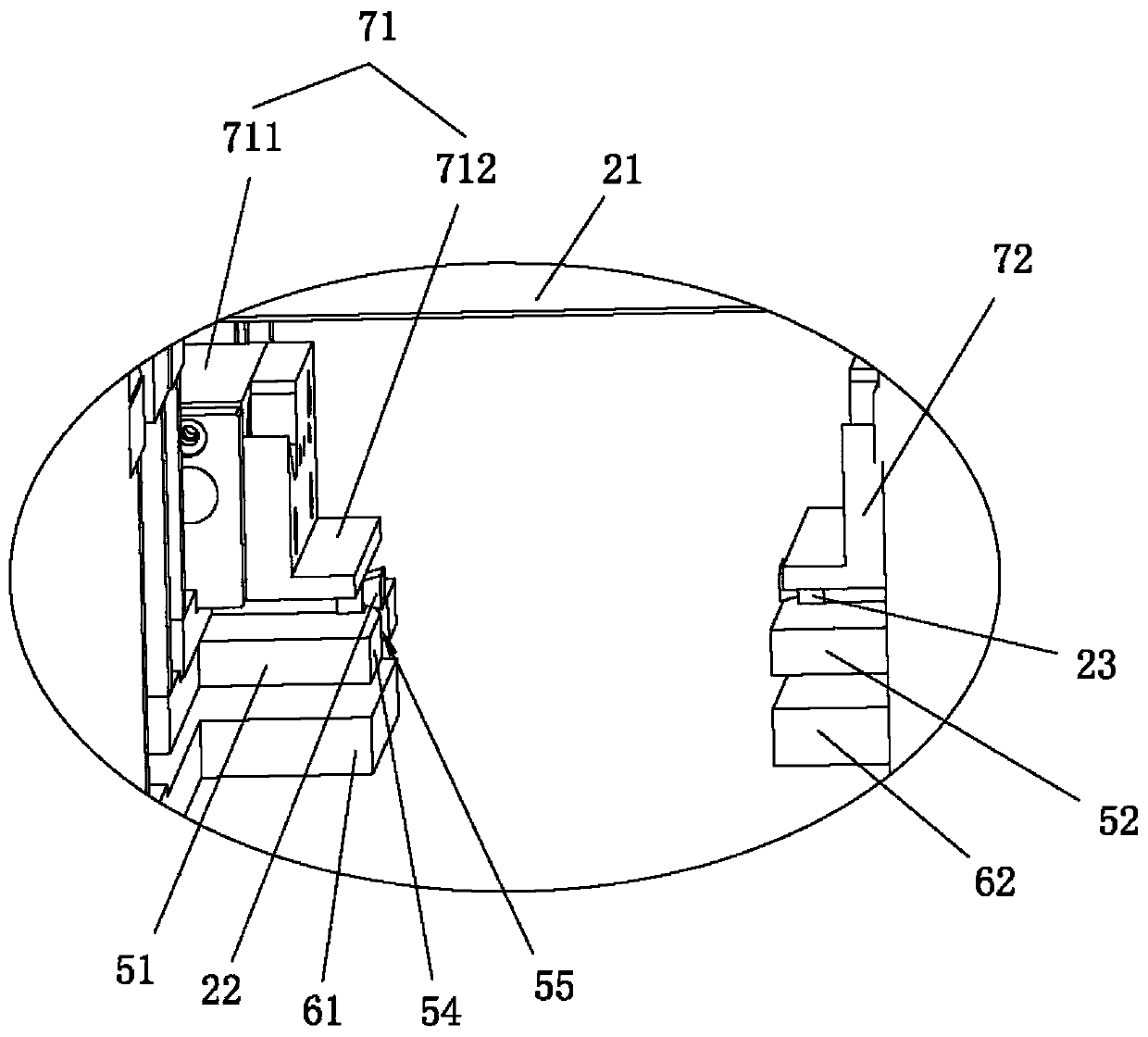

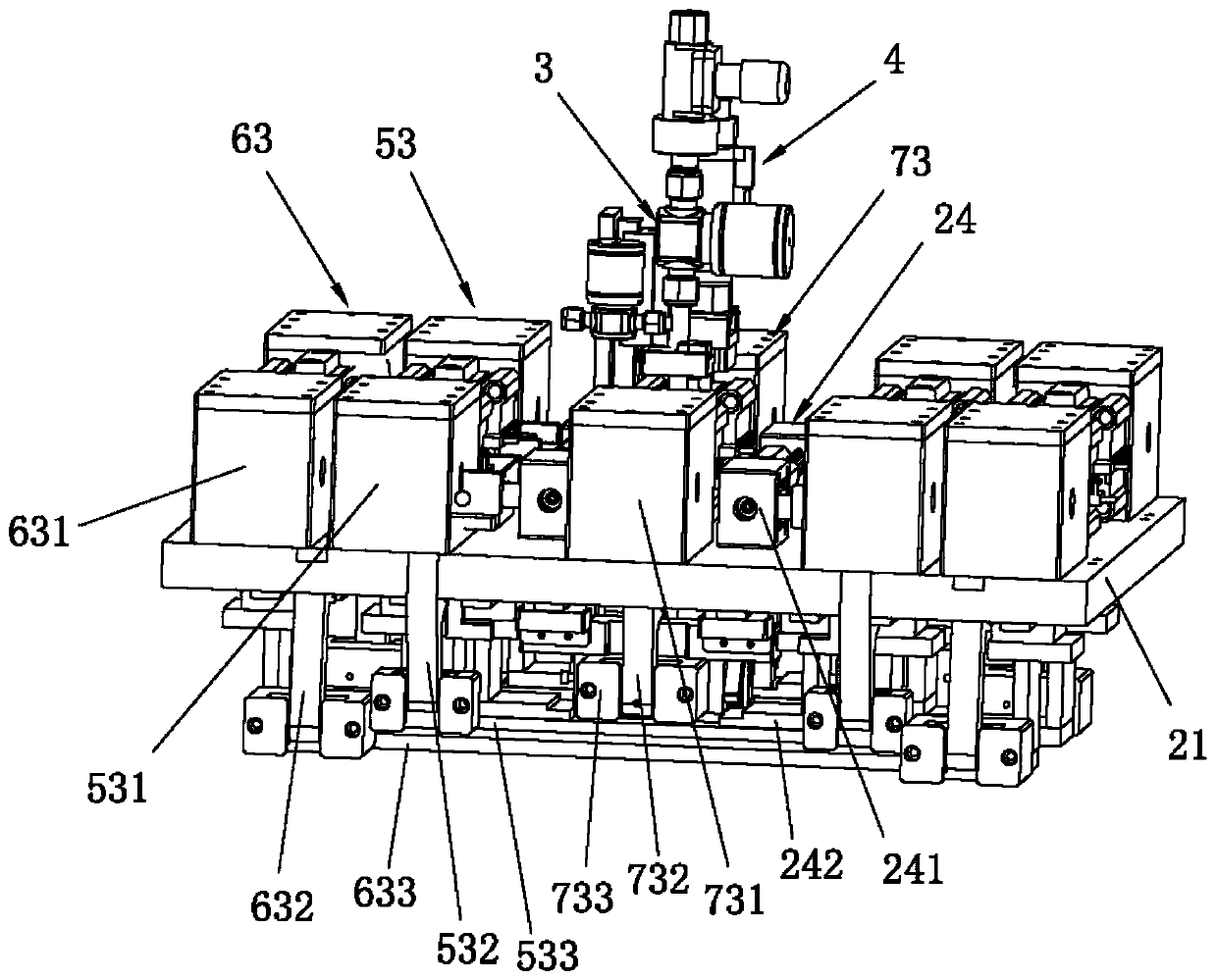

[0027] Such as Figure 1 to Figure 8 As shown, a vacuum liquid injection device provided by the present invention includes a clamping mechanism for clamping the main body of the battery, a bag opening mechanism 2 for opening the bag opening of the battery air bag, and a bag opening mechanism 2 for pumping the battery air bag. Vacuum liquid injection mechanism 3 for vacuuming and liquid injection, a lifting drive mechanism for driving the output end of the vacuum liquid injection mechanism 3 to insert or remove the pocket of the battery air bag 4, and a lifting drive mechanism for tightening the pocket of the battery air bag to A closing sealing mechanism 5 for sealing the gap between the bat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com