Live metal and method for preparing same

A manufacturing method and metal technology, applied in metal material coating technology, patterns imitating natural patterns, decorative arts, etc., can solve the problems that there are no specific disclosed patterns with various color aesthetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

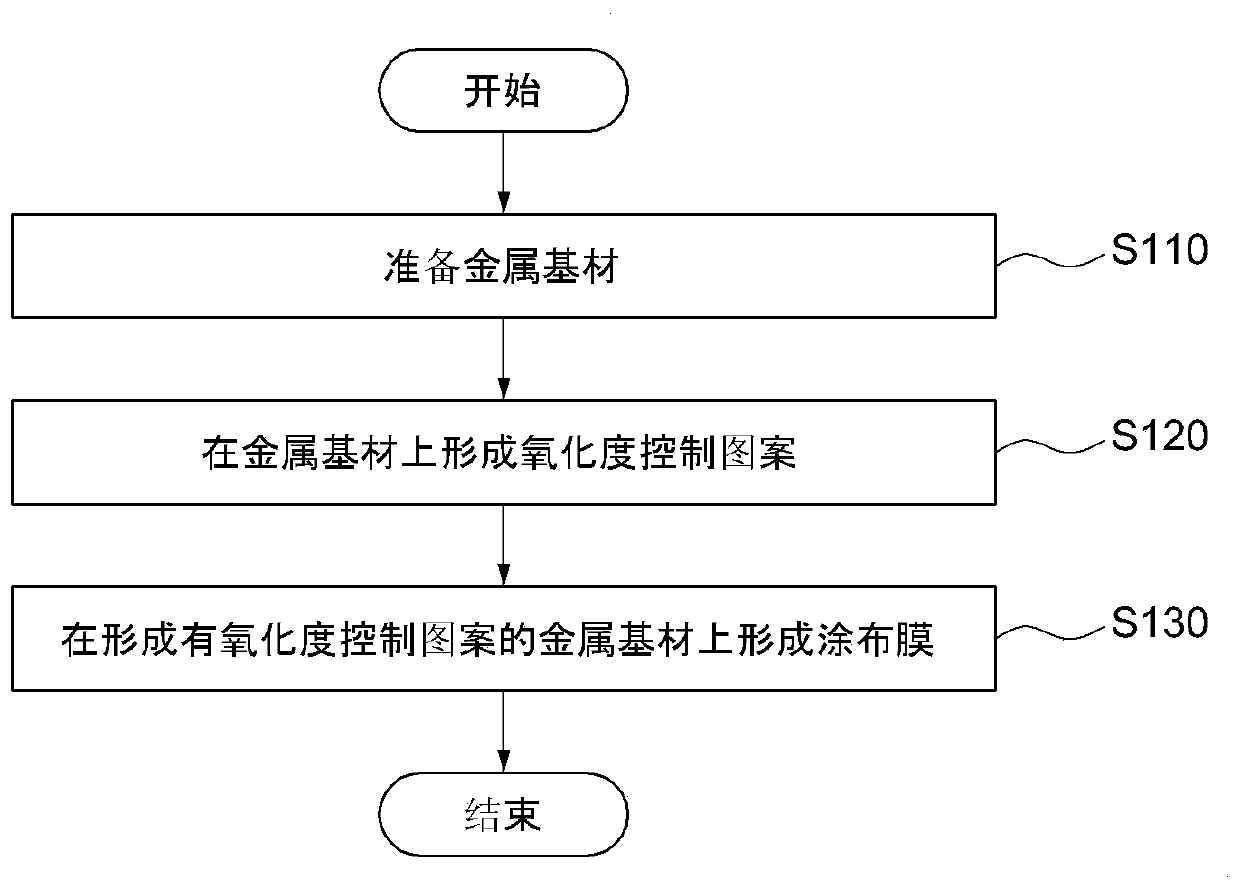

Method used

Image

Examples

Embodiment 1

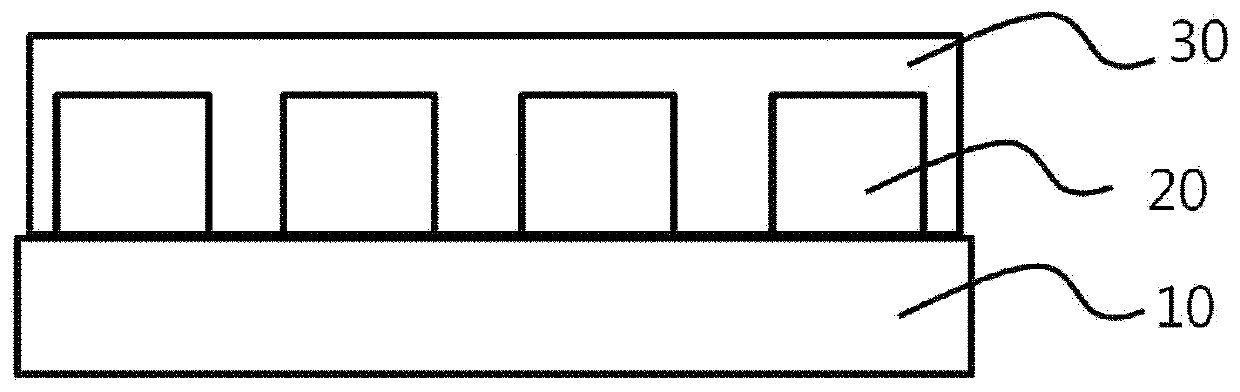

[0100] 1. Oxidation degree control pattern is formed on the metal substrate

[0101] After the carbon tape is attached to the copper sheet, the surface of the copper sheet to which the carbon tape is attached is subjected to a low-temperature heat treatment at 40° C., so that the carbon-based organic matter of the carbon tape remains, and the carbon tape is torn off to form an oxidation degree control pattern.

[0102] 2. Form coating film

[0103] On the copper sheet where only the carbon-based organics remain, the TiO 2 Sputtering was performed for 30 minutes to form a coating film.

[0104] 3. Accelerated oxidation treatment

[0105] The surface of the thin copper plate on which the coating film was formed was subjected to a high-temperature heat treatment at a temperature of 250° C. for 30 minutes.

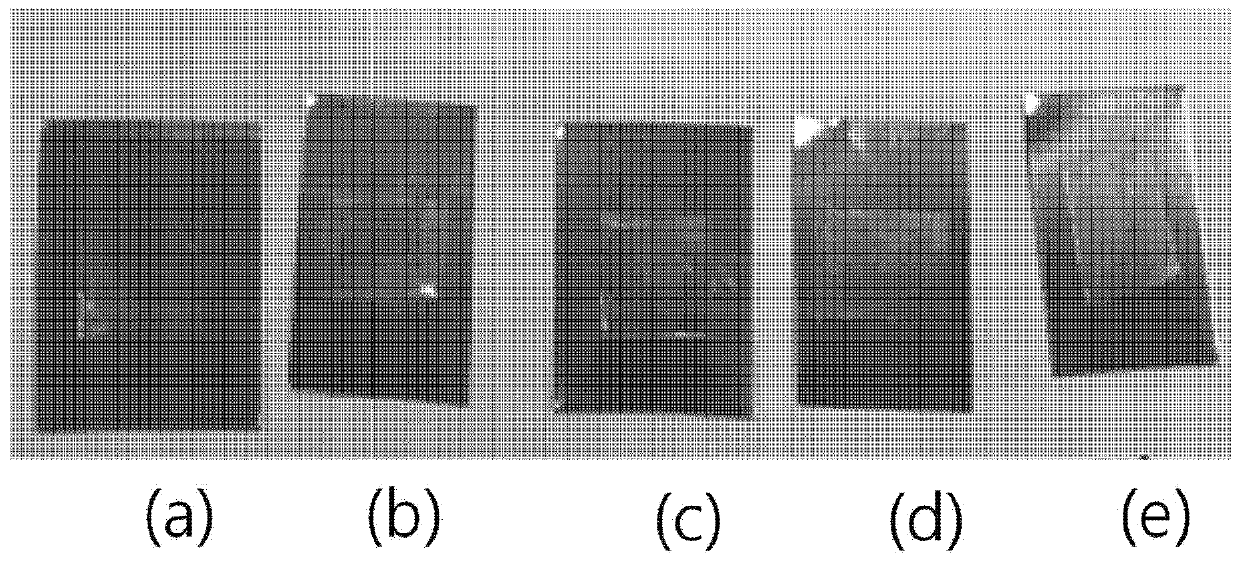

Embodiment 2

[0107] Except that the temperature of the low-temperature heat treatment stage was set to 50° C., it was performed in the same manner as the method of Example 1 above.

Embodiment 3

[0109] Except that the temperature in the low-temperature heat treatment stage was set to 60° C., it was performed in the same manner as the method of Example 1 above.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com