Prevention method of molten iron oxidation during smelting iron in cupola

A technology of cupola and molten iron, which is applied in the field of measures to prevent oxidation of cupola molten iron, can solve problems such as poor fluidity of molten iron and affect the internal quality of products, and achieve the effects of improving casting quality, saving raw materials, and reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

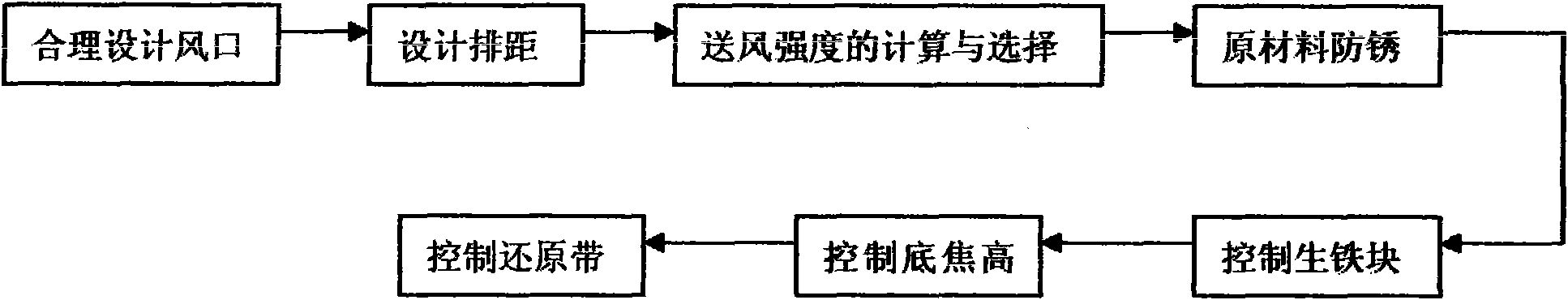

Method used

Image

Examples

Embodiment Construction

[0007] The reaction of carbon in a cupola: C+O 2 →CO 2 , CO+C→CO 2 , Since the activation ability of carbon and oxygen to generate carbon dioxide is lower than that of carbon monoxide, carbon dioxide is mainly generated in the oxidation zone where free oxygen exists. Under certain conditions, the height of the oxidation zone is greatly affected by the wind volume. Generally, when the coke consumption is constant, with the increase of the air supply volume, the oxidation zone of the cupola grows, and the C+O 2 →CO 2 The trend increases, the oxidizing atmosphere in the furnace increases, and the oxidizing property of molten iron increases. The greater the air volume, the stronger the degree of oxidation. Therefore, the air supply volume must be calculated.

[0008] 1. Reasonably design the air outlet

[0009] For small and medium-sized cupolas (3-5) t / h, each row of tuyere is designed with 6-8 outlets, the upper tuyere is slightly smaller than the lower tuyere, and the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com