Individualized customized pocket design method based on 3D printing technology and product

A 3D printing and design method technology, applied in the fields of colostomy, additive processing, medical science, etc., can solve the problems of liquid leakage, air leakage, inaccurate opening, etc., and achieve high practicability, large economic burden, and high cost performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

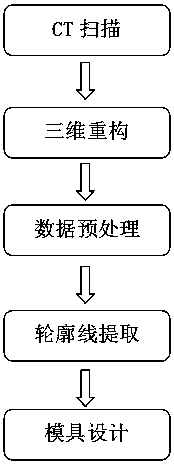

[0033] The personalized customized manufacturing pocket design method based on 3D printing technology of the present embodiment, such as figure 1 As shown, the method is realized through the following steps:

[0034] Step 1, obtaining CT scan data of the patient's abdominal artificial anus area;

[0035] Step 2. Based on the CT scan data, reconstruct the three-dimensional model of the artificial anostomy and surrounding skin;

[0036] Step 3. Preprocessing the reconstructed 3D model data, including: smoothing, removing noise and impurity points, and simplifying the model;

[0037] Then draw the contour curve of the stoma according to the graphics presented by the preprocessed three-dimensional model, and save the drawn contour curve as a file in iges format;

[0038] Step 4. According to the 3D model data of the stoma, design the silicone base model of the ostomy bag, including the film structure used to wrap the artificial anus and reflect the shape of the 3D model of the s...

specific Embodiment approach 2

[0044] The difference from the specific embodiment 1 is that, in the design method of the ostomy bag auxiliary cutting device based on 3D printing technology in this embodiment, in the second step, the process of reconstructing the three-dimensional model of the artificial anostomy and surrounding skin, Specifically: Based on the CT scan data, use the medical reconstruction software Mimics to reconstruct the three-dimensional model of the artificial anostomy and surrounding skin.

[0045] Operation process: 1. Import CT data into Mimics21 software in .dicom format;

[0046] 2. Use the Threshold command in the SEGMENT module in the Mimics21 software to segment the CT data, and use the Skin Tissue (CT, Adult) to extract the skin data;

[0047] 3. Reconstruct the 3D model of the extracted data and export it in .STL format.

specific Embodiment approach 3

[0049] Different from the second specific embodiment, the personalized ostomy bag design method based on 3D printing technology in this embodiment, in the third step, the preprocessing of the reconstructed three-dimensional model data is performed using the industrial design software GeomagicWrap The software performs further preprocessing on the reconstructed 3D model data.

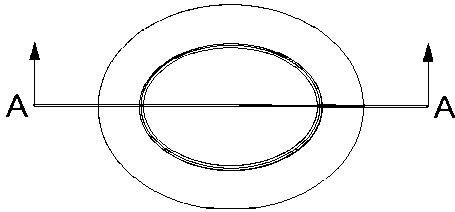

[0050] 1. Import the reconstructed 3D model data into Geomagic Wrap software, first use the Trim command in Polygons to trim the model data, and only keep the stoma and its surrounding data;

[0051] 2. Use the Quicksmooth command to smooth the model data;

[0052] 3. Use the Offest command in the Polygons module to design the membrane structure with equal wall thickness along the stoma.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com