Catalyst for preparing α-olefin from n-alcohol, preparation method and application thereof

A catalyst, a technology for catalytic reaction, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc. and other problems, to achieve high α-olefin yield, high mechanical strength and thermal stability, and maintain the effect of high-efficiency reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

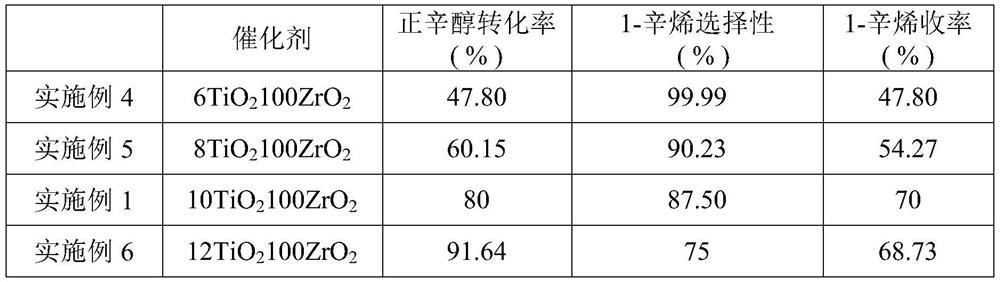

[0080] Embodiment 1: the preparation of catalyst and Application in the preparation of 1-octene from n-octanol

[0081] Weigh 104.53g zirconium source Zr (NO 3 ) 4 ·5H 2 O dissolved in deionized water, Zr(NO 3 ) 4 ·5H 2 The mass ratio of O to deionized water is 1:25. After the solution is clear and transparent, 12.78 g of tetrabutyl titanate, the precursor of the modifier, is added dropwise. L of ammonia water is subjected to precipitation reaction, and the pH value of the reaction solution is controlled to be 9. After the reaction is completed, it is allowed to stand for 12 hours, and then filtered and washed to obtain a precipitated product. The precipitation product was extruded into strips, dried and calcined at 600 °C for 4 h to obtain the modifier as TiO 2 ZrO 2 catalyst, where TiO 2 with ZrO 2 The mass ratio is 10:100.

[0082] The catalyst prepared above was put into a tubular fixed-bed reactor, the inner diameter of the reactor was 10 mm, and the filling am...

Embodiment 2

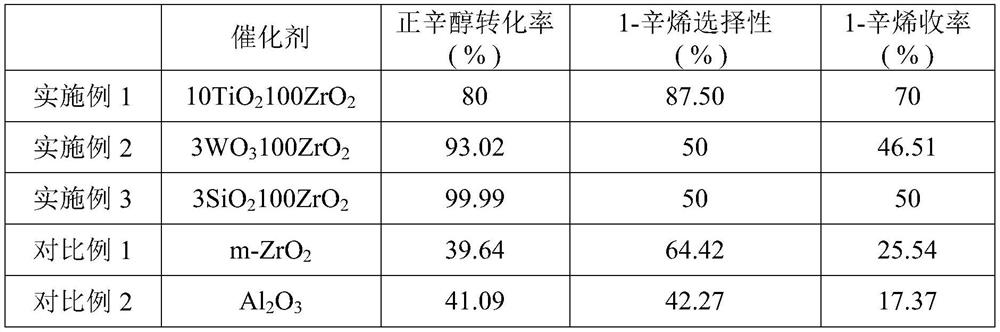

[0085] Similar to Example 1, the difference is that in the preparation of the catalyst, the modifier precursor is 0.9557g of ammonium metatungstate, which is directly added to the solution containing the zirconium source, and the modifier is WO. 3 ZrO 2 catalyst, where WO 3 with ZrO 2 The mass ratio is 3:100. The reaction results are shown in Table 1.

Embodiment 3

[0087]Similar to Example 1, the difference is that in the preparation of the catalyst, the modifier precursor is 0.9 g of silica gel, which is directly added to the solution containing the zirconium source, and the modifier is SiO 2 ZrO 2 catalyst, where SiO 2 with ZrO 2 The mass ratio is 3:100. The reaction results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com