Plastic craft product spraying and processing equipment

A processing equipment and process technology, which is applied in the field of plastic handicraft processing equipment, can solve the problems of low quality plastic products and polishing of craft products, and achieve the effects of reasonable structure, strong practicability and novel design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

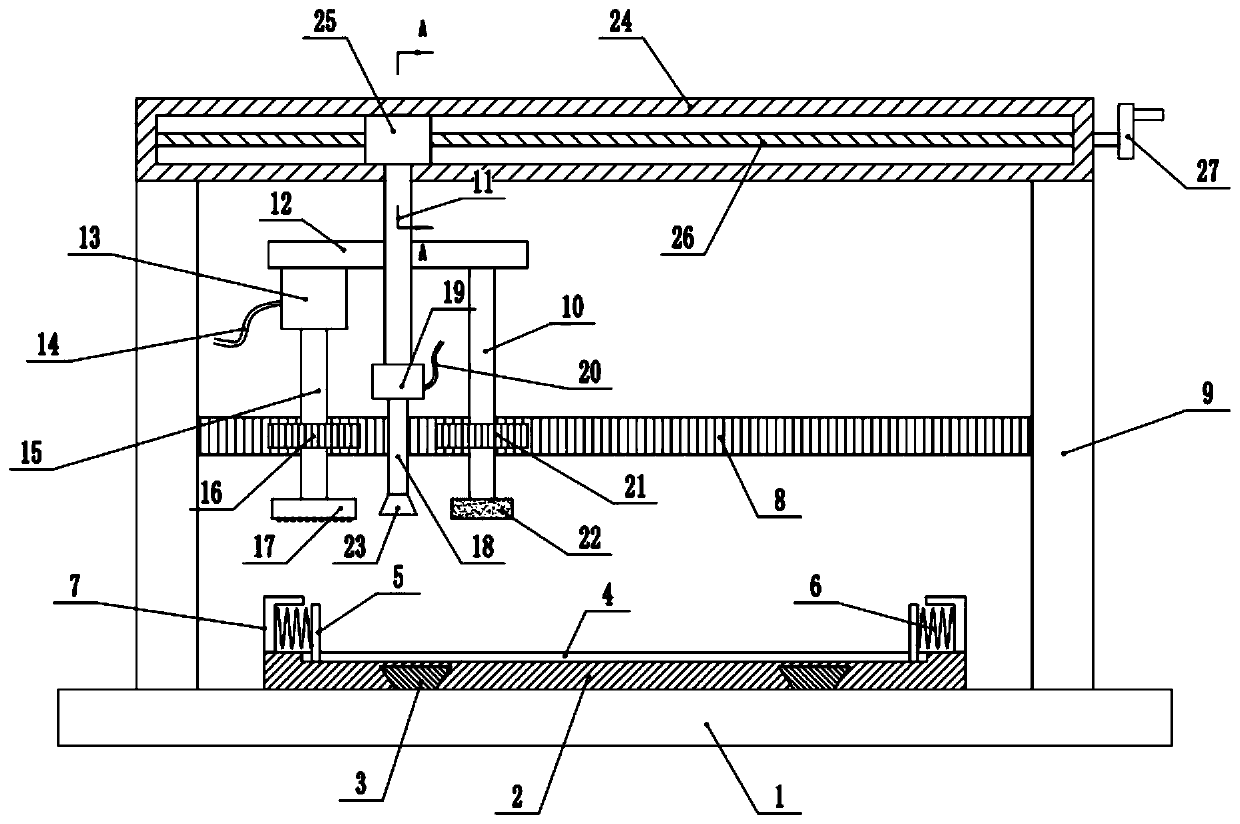

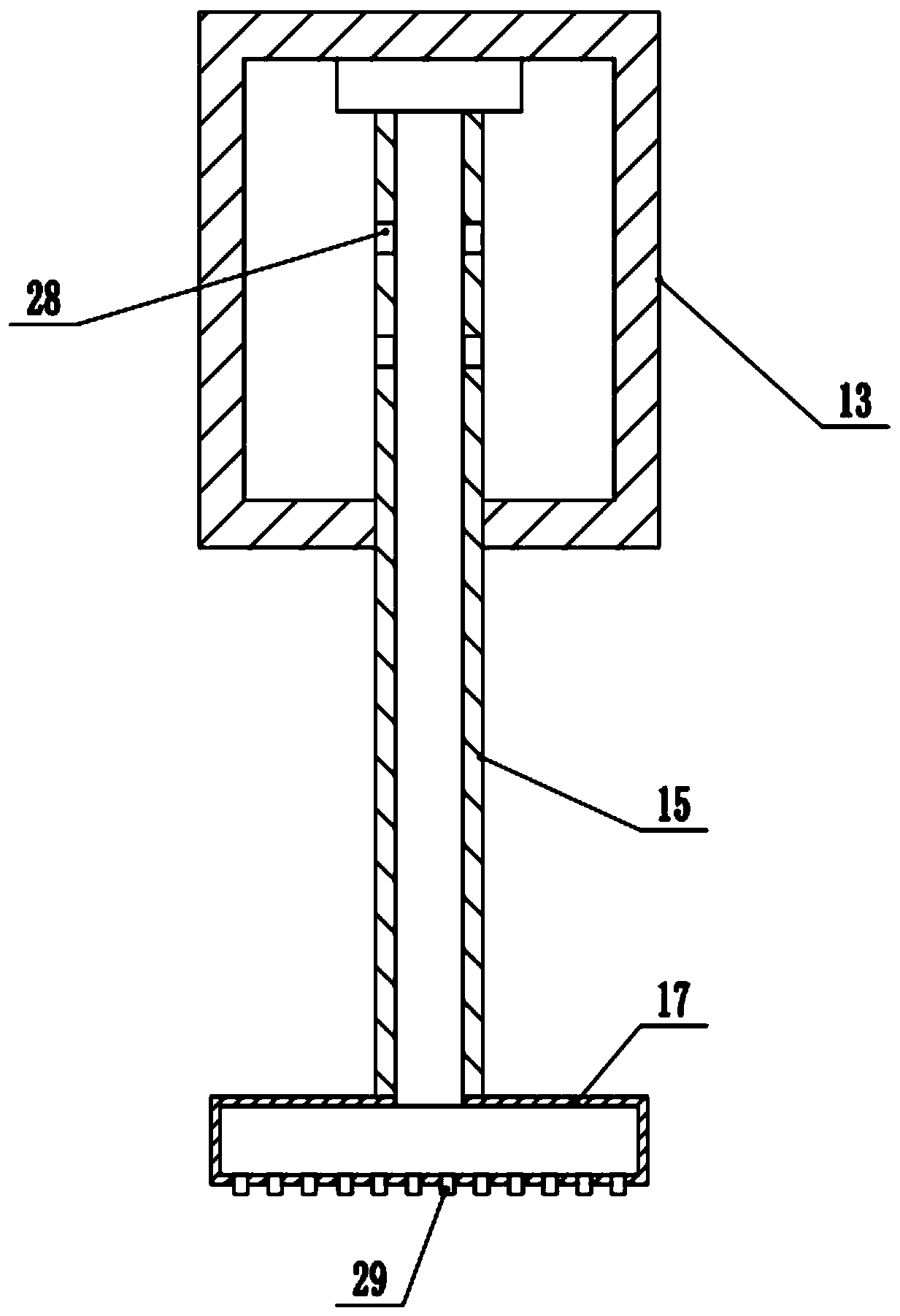

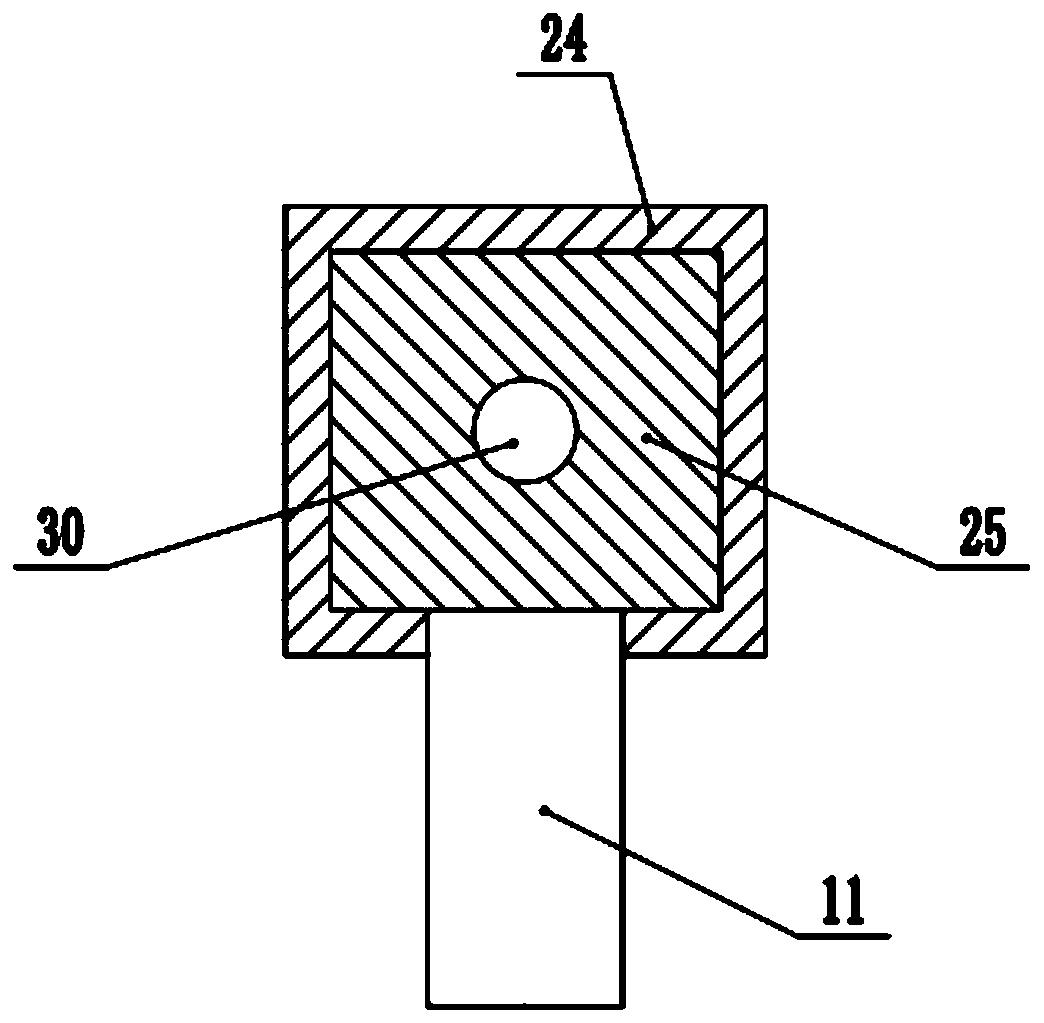

[0027] refer to Figure 1~3 , in an embodiment of the present invention, a spraying processing equipment for plastic craft products includes a fixed bottom plate 1, and support frames 9 are installed on both sides of the upper end of the fixed bottom plate 1, on the one hand, it realizes the support and fixation of the fixed rack 8, on the other hand To realize the support and fixation of the limit frame 24, the middle part of the support frame 9 is equipped with a fixed rack 8, and the fixed rack 8 is respectively meshed with the first gear 16 and the second gear 21, so that the first gear 16 and the second gear The gear 21 rotates, the limit frame 24 is installed on the upper end of the support frame 9, and the limit block 25 is installed inside the limit frame 24, and the middle part of the limit block 25 is connected with the screw mandrel 26 through the internal thread hole 30, realizing the internal thread 30 and the position limit. Frame 24 acts as a limiter for the lim...

Embodiment 2

[0029] In another embodiment of the present invention, the difference between this embodiment and the above-mentioned embodiment is that baffles 7 are installed on both sides of the upper end of the workbench 2, and a clamping spring 6 is installed on the inside of the baffle 7 for Realize the left and right buffer support of the clamping plate 5, the other end of the clamping spring 6 is connected with the clamping plate 5, and the middle part of the upper end of the workbench 2 is provided with a guide groove 4 that cooperates with the clamping plate 5 for clamping The left and right movement of the plate 5 is guided, so that the clamping plate 5 can well polish the craft products that need to be sprayed.

[0030] The present invention is suitable for processing and horizontal bases of handicrafts. When in use, put the corresponding handicrafts in the middle of the clamping plate 2 on the workbench, perform clamping and positioning by the clamping spring 6, and then turn the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com