Double-die head coating device and pole piece coating process thereof

A technology of coating device and coating process, which is applied to devices for coating liquid on surfaces, coatings, electrode manufacturing, etc. , the effect of reducing the risk of abnormality, improving production efficiency and production excellence rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

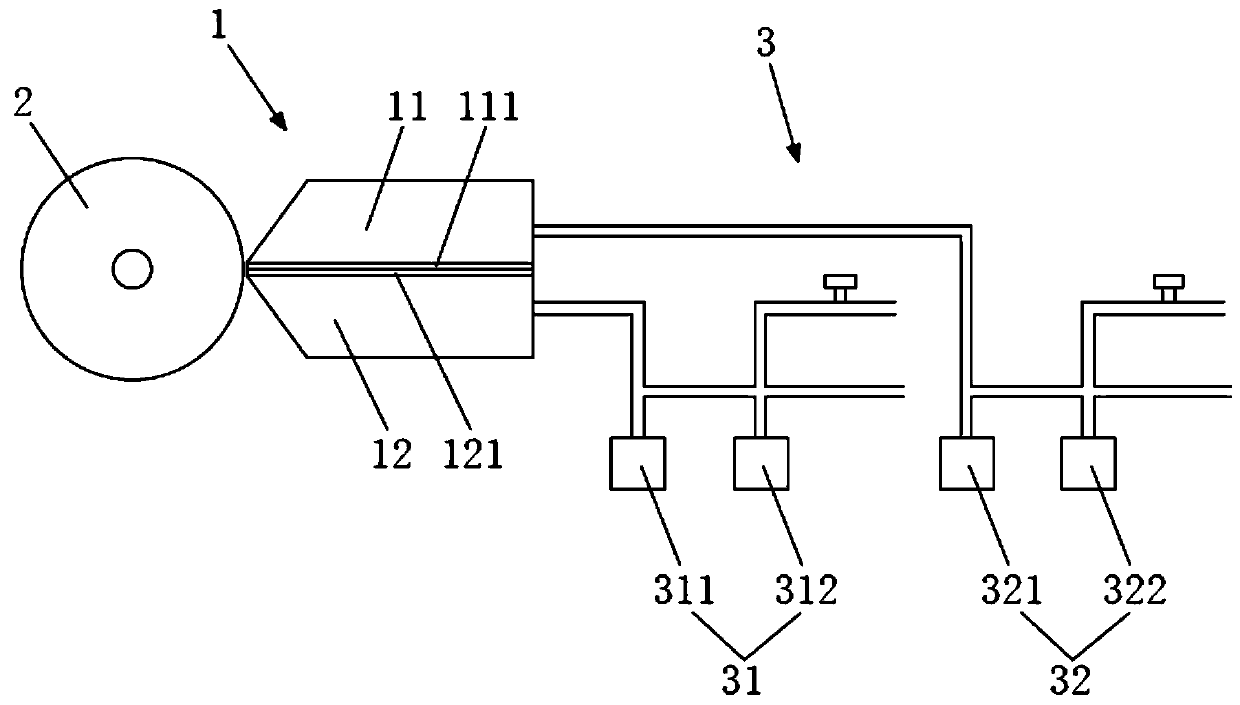

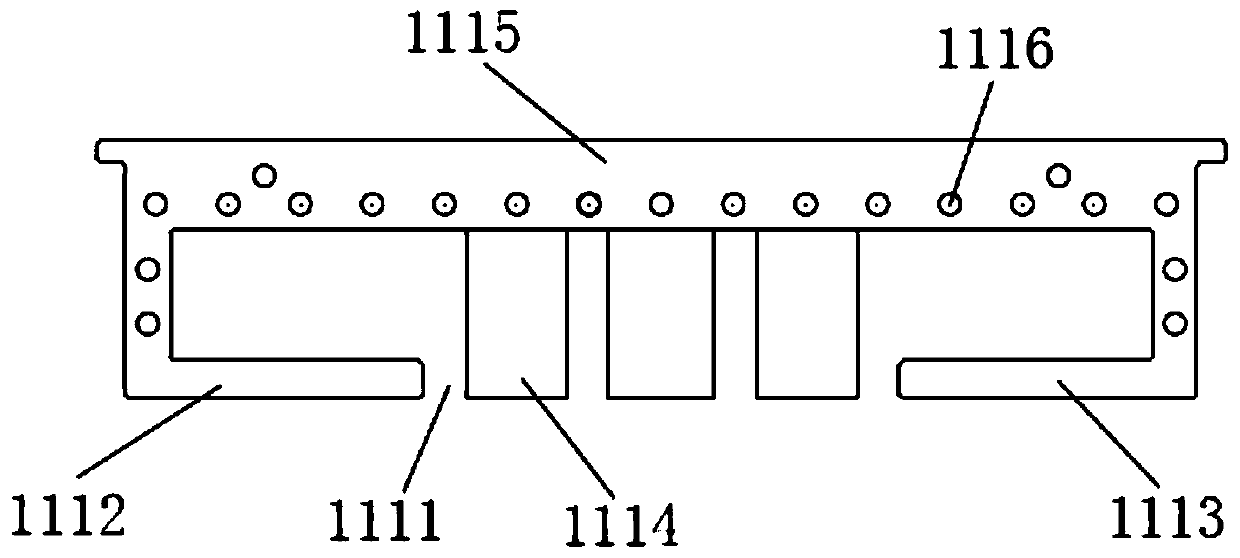

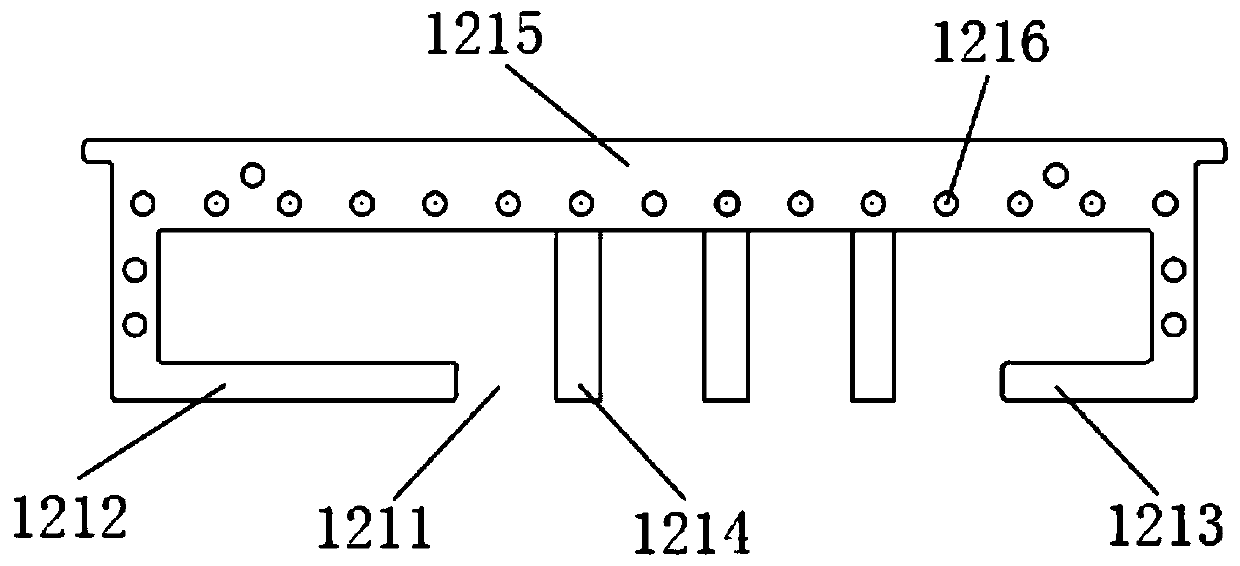

[0035] Such as Figure 1~5 As shown, a double die head coating device includes a die head structure 1 and a roller shaft structure 2 arranged in cooperation with the die head structure 1. The die head structure 1 includes a first die head 11 and a corresponding arrangement with the first die head 11. The second die head 12, the first die head 11 is provided with a first gasket 111, the second die head 12 is provided with a second gasket 121, the first gasket 111 and the second gasket 121 are correspondingly arranged on the first mold Between the head 11 and the second die head 12, wherein, the first gasket 111 is provided with a first fixing hole 1116, and is fixed on the first die head 11 by cooperating with screws, and the second gasket 121 is provided with a second The fixing hole 1216 is fixed on the second die head 12 by screwing with the screw; the first gasket 111 has a plurality of first flow openings 1111, the second gasket 121 has a plurality of second flow openings ...

Embodiment 2

[0046] A pole piece coating process of a double-die coating device, the double-die coating device is the double-die coating device of any one of the above-mentioned sections, and the pole piece coating process comprises in turn:

[0047] The first coating stage: the roller shaft structure 2 drives the pole piece 4 to rotate, and the first die head 11 and the second die head 12 coat the rotating pole piece 4 at the same time, and the coating is respectively drawn from multiple first flow ports 1111 and multiple A second flow port 1211 flows out, so that the pole piece 4 gets the first complete paint area 411 covered by the paint, and a plurality of first flow ports 1111 and a plurality of second flow ports 1211 correspond to obtain the first complete paint area 411;

[0048] Partial coating stage: the first die head 11 stops coating, the second die head 12 continues to coat the rotating pole piece 4, and the paint flows out from a plurality of second branch ports 1211, so that t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com