Automatic spot welding device for sealing plate of filter

An automatic spot welding and sealing plate technology, which is applied in the filter field, can solve the problems that cannot be directly applied to the spot welding operation of the filter sealing plate, and achieve the effect of high spot welding efficiency, convenient operation and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

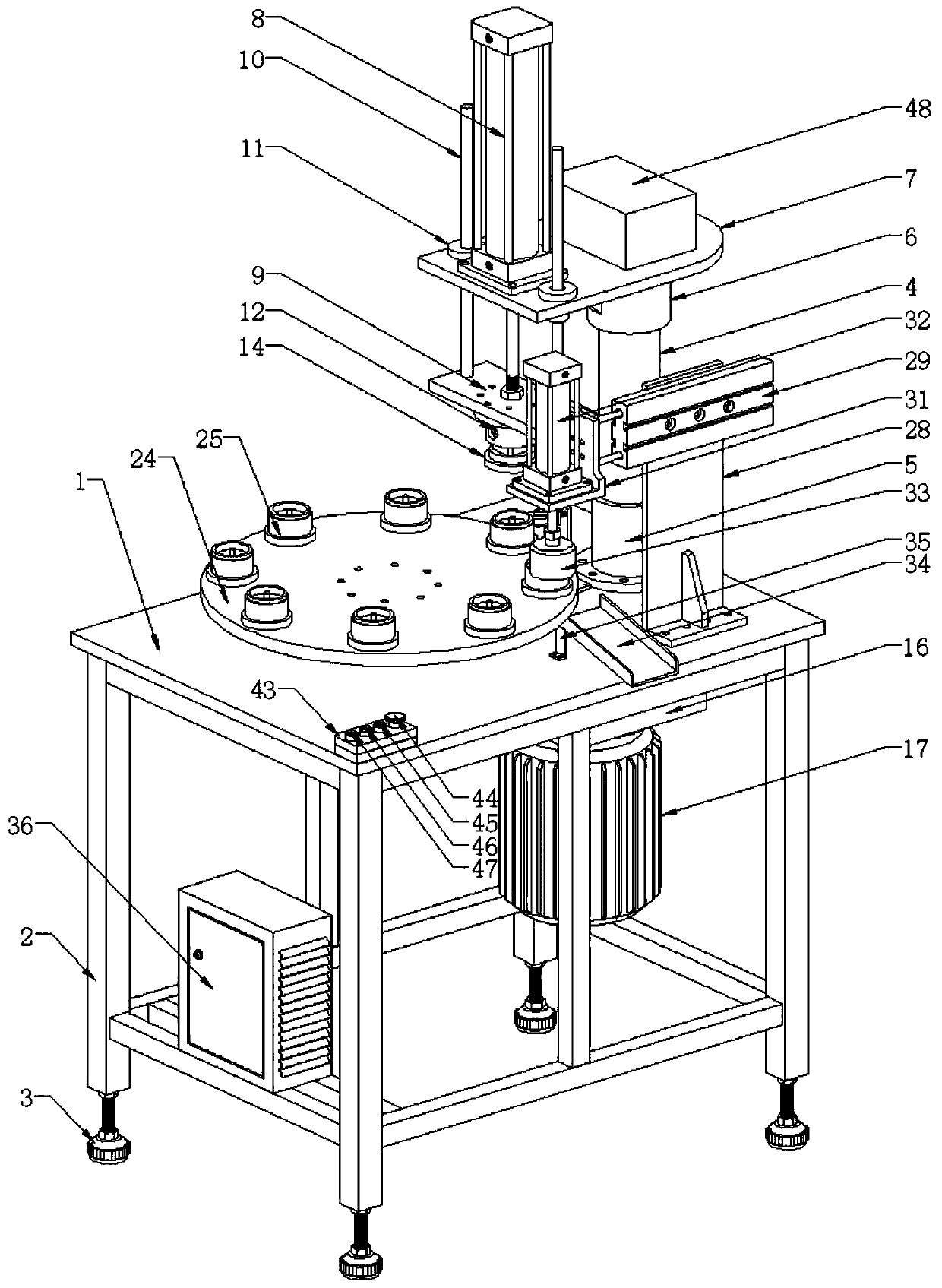

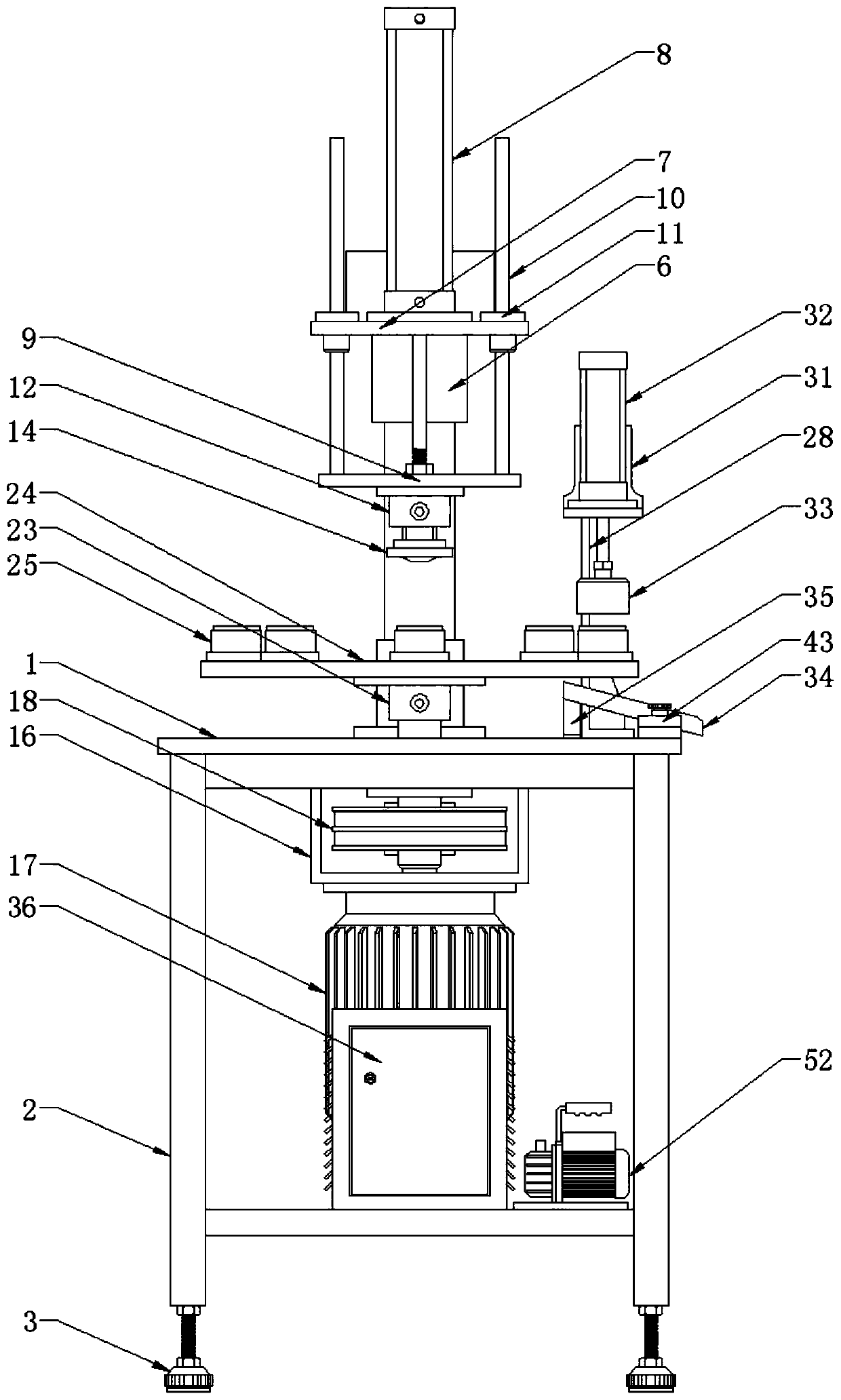

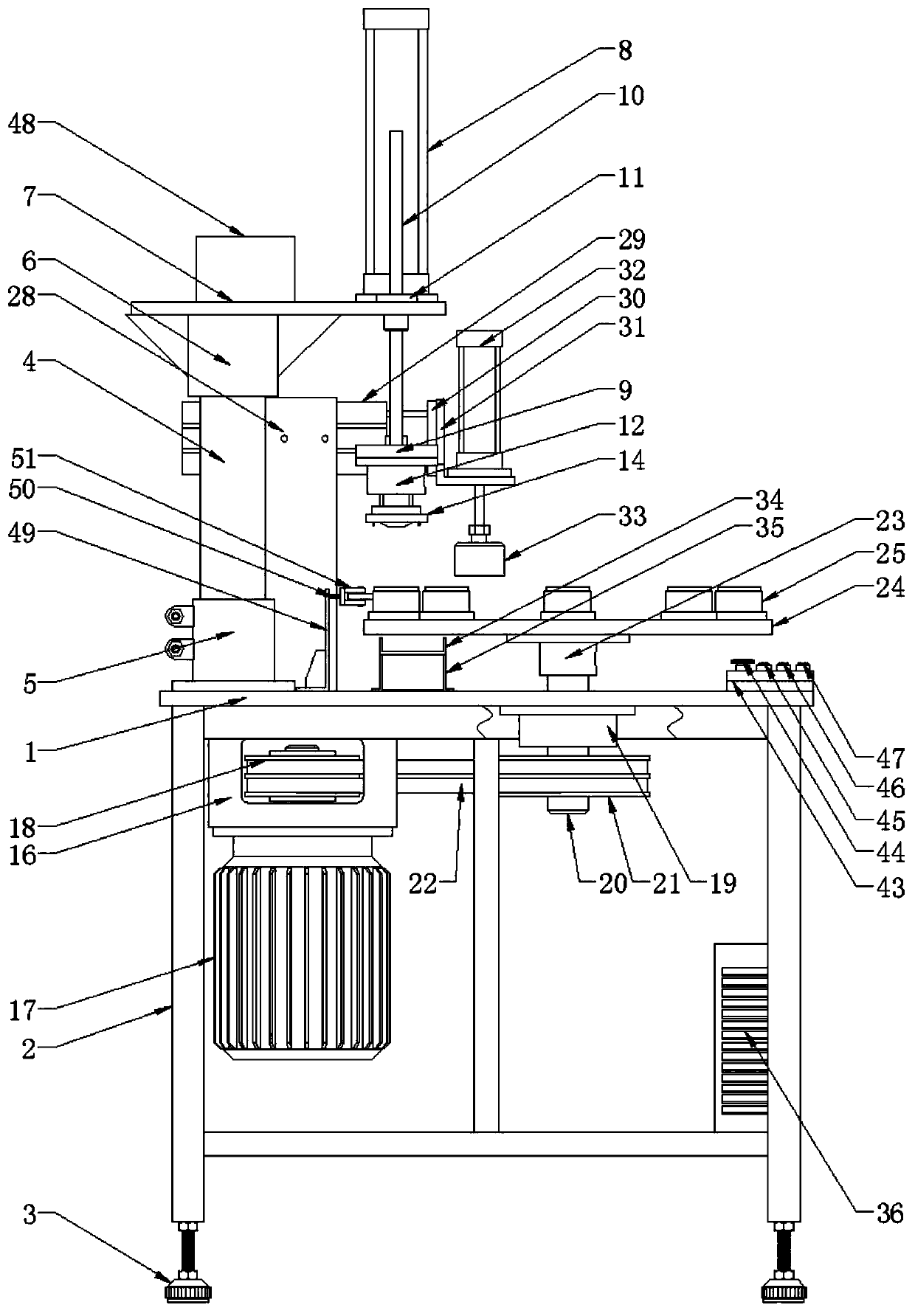

[0028] Such as Figure 1 to Figure 10 As shown, an automatic spot welding device for a filter sealing plate includes a support plate 1, a support frame 2, a foot 3, a spot welding assembly, a placement assembly and a retrieving assembly, and the support plate 1 is horizontally installed on the support frame 2 At the top, the legs 3 are evenly distributed on the bottom of the support frame 2, the spot welding assembly is arranged on the top of the support plate 1 and used for spot welding the sealing plate of the filter, and the placement assembly is arranged in the center and front Above the support plate 1, it is used to place the sealing plate of the filter to be spot-welded, and the take-up assembly is arranged next to the spot-welding assembly and is used to remove the welded filter sealing plate.

[0029]In the present invention, the spot welding assembly includes a mounting column 4, a welding cylinder 8 and a welding block 14, the mounting column 4 is vertically arrange...

Embodiment 2

[0033] Such as Figure 1 to Figure 10 As shown, an automatic spot welding device for a filter sealing plate includes a support plate 1, a support frame 2, a foot 3, a spot welding assembly, a placement assembly and a retrieving assembly, and the support plate 1 is horizontally installed on the support frame 2 At the top, the legs 3 are evenly distributed on the bottom of the support frame 2, the spot welding assembly is arranged on the top of the support plate 1 and used for spot welding the sealing plate of the filter, and the placement assembly is arranged in the center and front Above the support plate 1, it is used to place the sealing plate of the filter to be spot-welded, and the take-up assembly is arranged next to the spot-welding assembly and is used to remove the welded filter sealing plate.

[0034] In the present invention, the spot welding assembly includes a mounting column 4, a welding cylinder 8 and a welding block 14, the mounting column 4 is vertically arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com