Mechanical assembly control system and assembly method of cylinder body and composite cover

A technology of assembly control and combined cover, which is applied in the direction of manufacturing tools, metal processing equipment, metal processing, etc., can solve the problems of low assembly production efficiency of combined cover, large production line cost investment, small thickness of combined cover, etc., and achieve low labor intensity , Good assembly effect and simple assembly method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

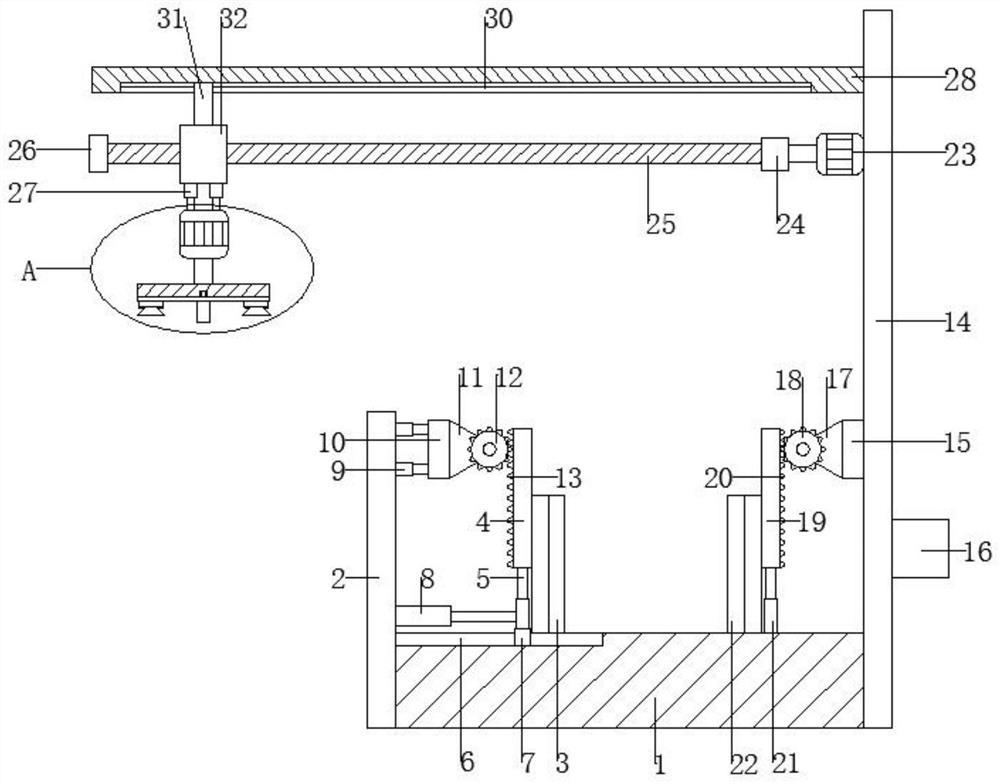

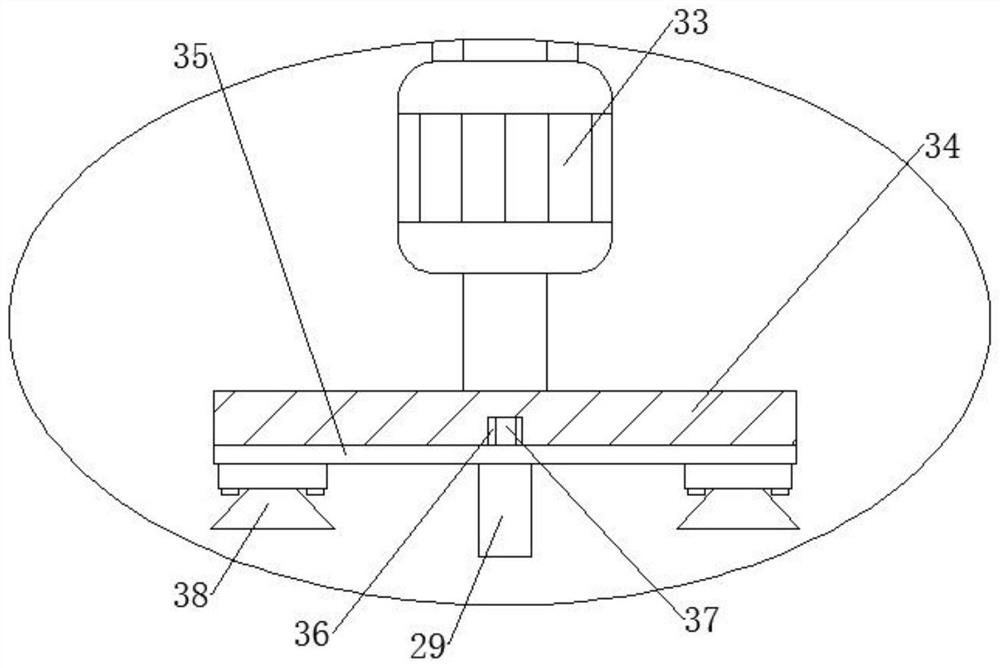

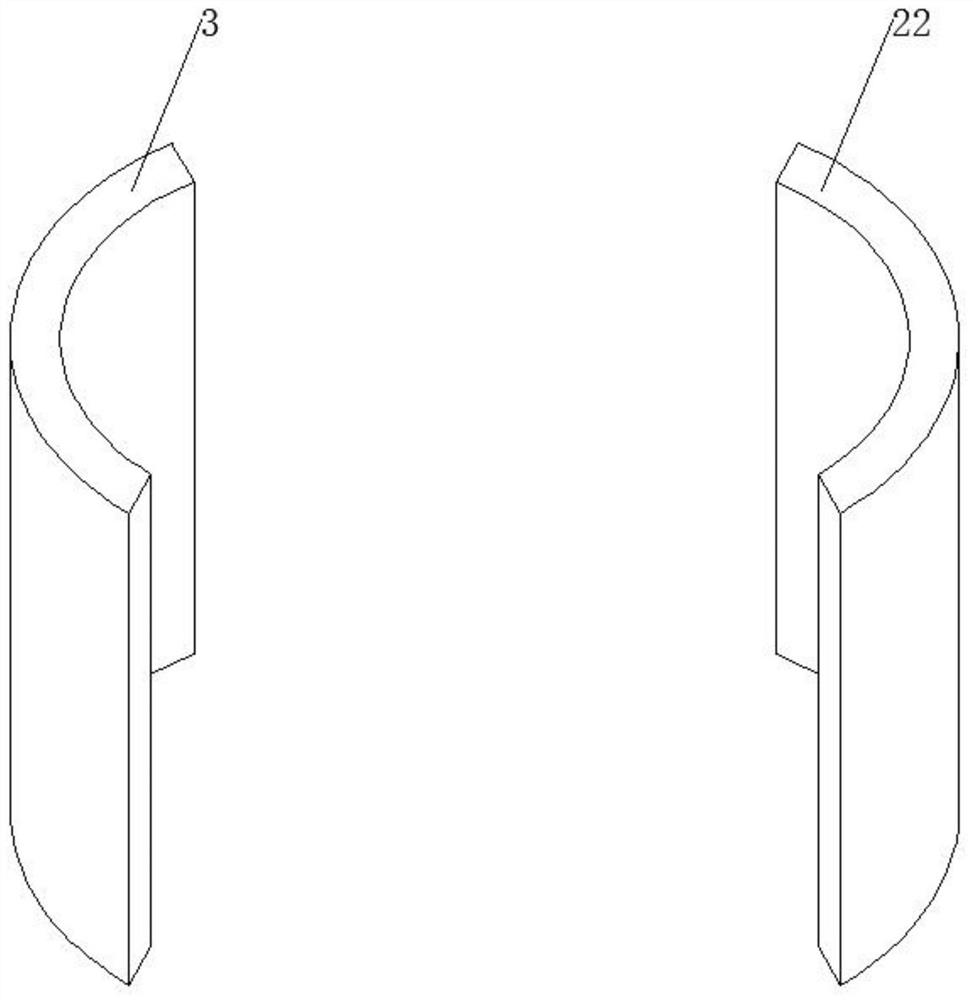

[0034] see Figure 1-4, a mechanical assembly control system for a cylinder body and a combination cover and an assembly method thereof, comprising a cylinder body (not shown in the figure), a combination cover (not shown in the figure), an assembly platform 1 and a PLC programmable controller 16, and the combination cover There is a positioning hole (not shown in the figure) in the middle of the upper end. The positioning hole is mainly used for the passage of the positioning block. The cylinder and the combination cover are connected by threads. The patent number "CN201510380016.4" records "a combination cover that automatically "Assembly system" has recorded the shape of the cylinder body and the combined cover in detail, which is a well-known technology for those skilled in the art, so it will not be shown in the figure, and will not be explained too much. The left and right ends of the assembly platform 1 are respectively fixedly connected with the left fixing seat 2 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com