Cable crane main cable dismantling construction method

A cable crane and construction method technology, which is applied to cable cranes, hoists, load suspending elements, etc., can solve the problems of long construction period, safety risks of high-altitude operations, and large resource occupancy, and achieve the effect of solving safety risks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in combination with specific embodiments. The specific embodiments are further explanations of the principles of the present invention and do not limit the present invention in any way. The same or similar technologies as the present invention do not exceed the protection scope of the present invention.

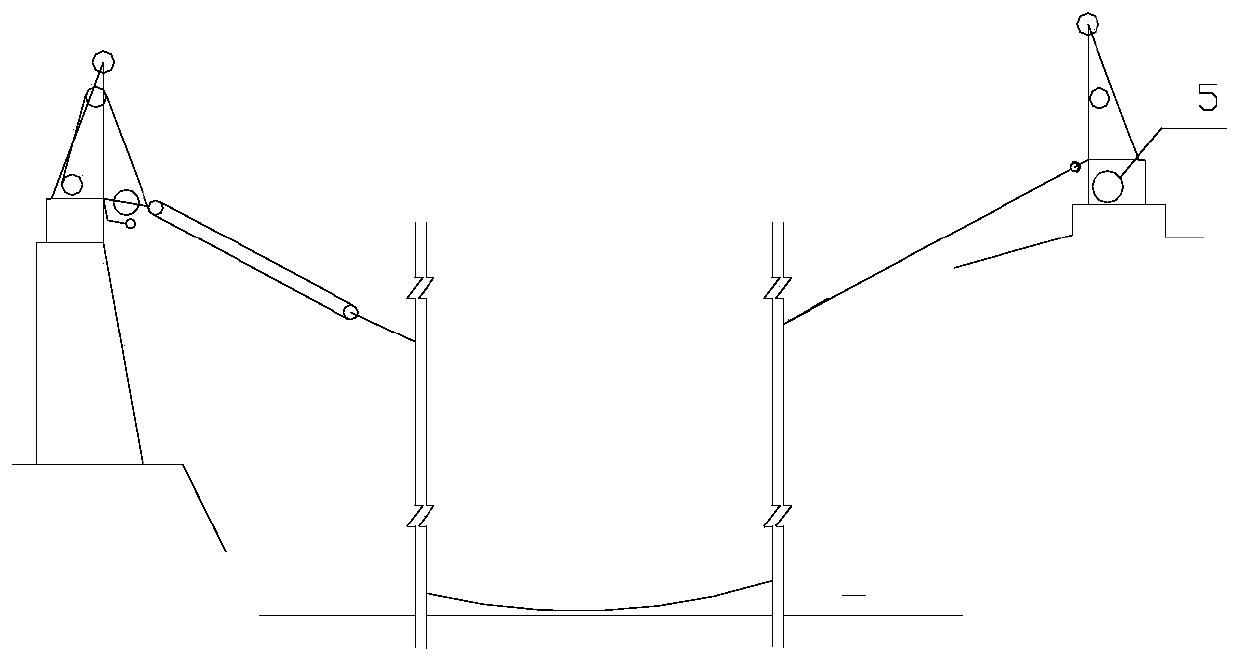

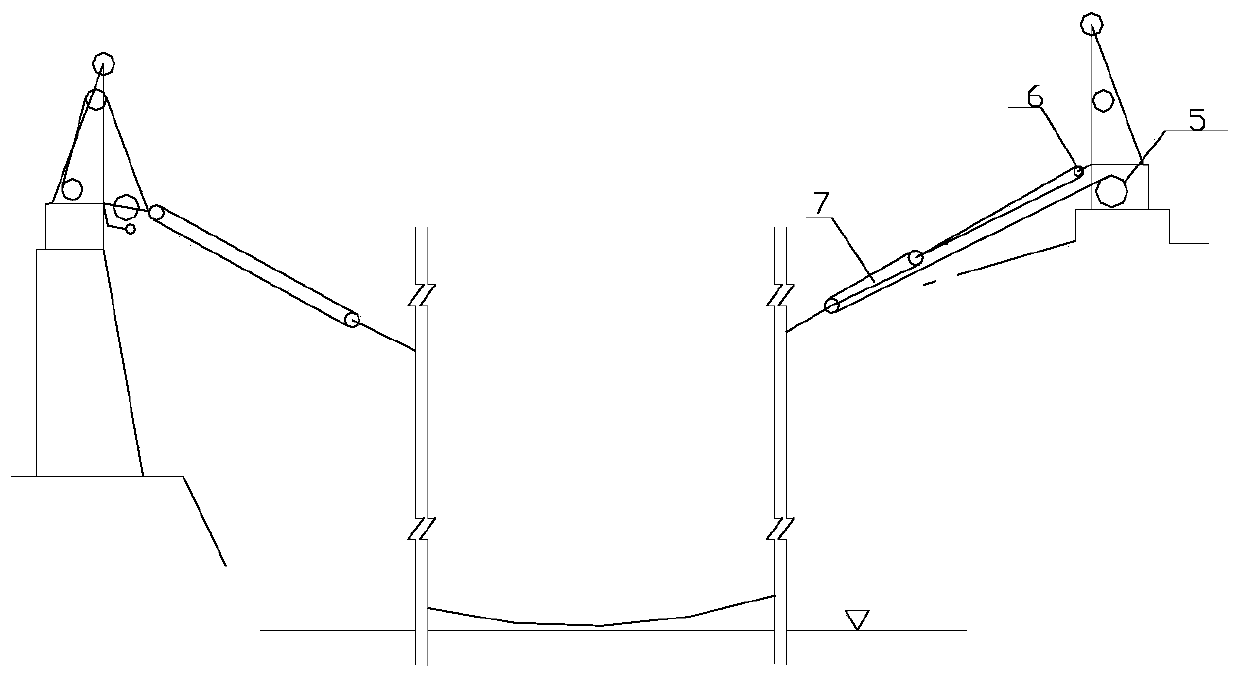

[0028] Combined with the drawings.

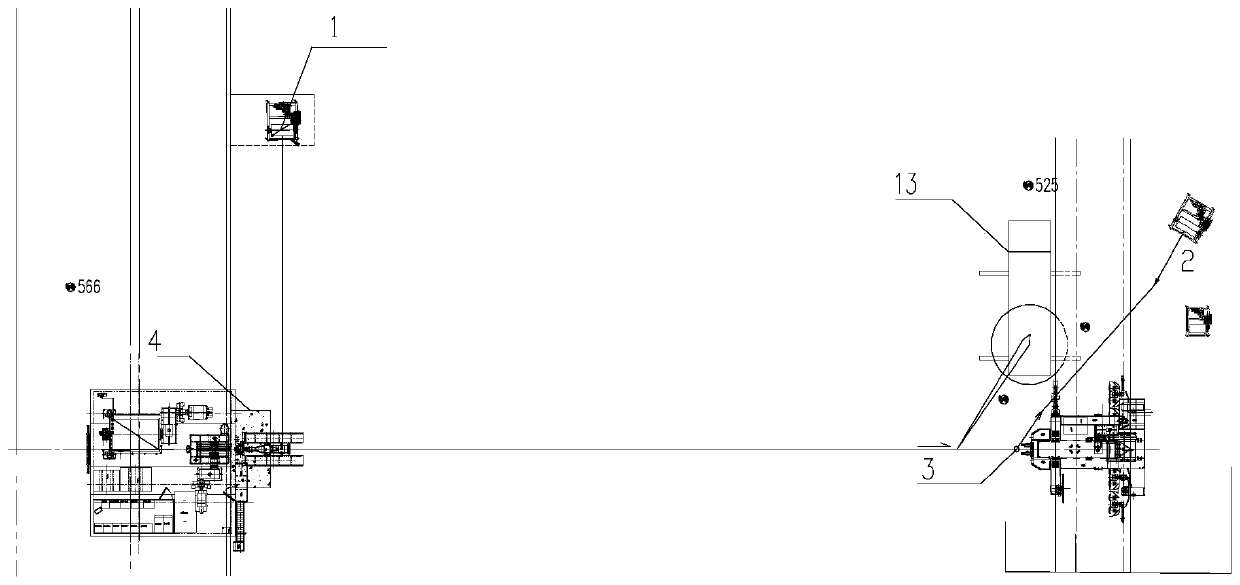

[0029] The method of the present invention will be described below by taking the removal of the main rope of a certain engineering cable crane as an example.

[0030] (1) Design and layout of towing rope-guided ground anchors: The towing rope-guided ground anchors are mainly used for the removal of the guided towing ropes of the main rope of the cable machine. The towing rope guided ground anchors of the main and auxiliary vehicles can be buried according to the site conditions, such as the main cable machine of the pavilion. Removal of the ropes. A 30t guided ground anchor is buried at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com