A combined separation method of lysozyme and ovotransferrin in egg white

A technology of ovotransferrin and lysozyme, applied in the field of protein separation and purification, can solve the problems of low separation efficiency and difficult industrialization, and achieve the effect of simple operation, low cost and high efficiency separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

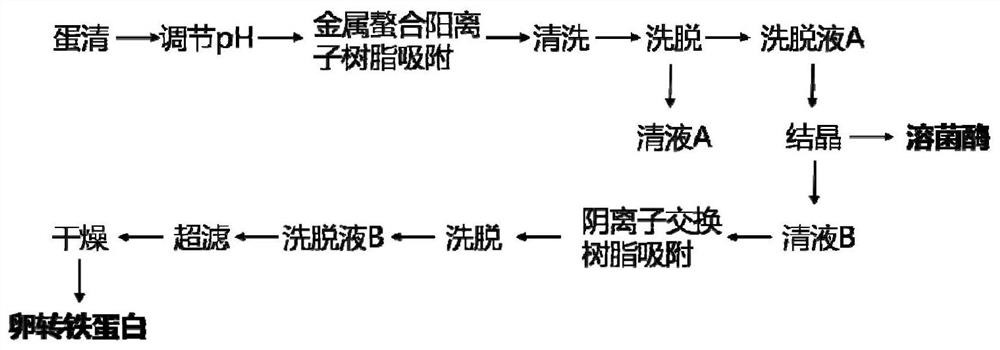

Method used

Image

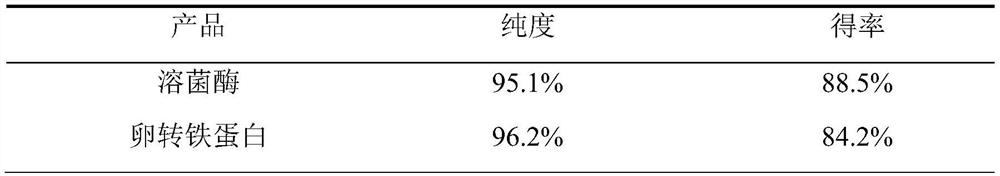

Examples

Embodiment 1

[0046] (1) Egg liquid pretreatment: Stir the egg white liquid and adjust the pH to 8;

[0047] (2) Adsorption by metal chelating cation resin: mix carboxyl type weak cation exchange resin and pretreated egg white liquid according to the ratio of material to liquid 1:5, add ferric chloride, so that the molar concentration of ferric chloride in egg white liquid is 0.2mmol / L, adsorbed for 5 hours, and removed the supernatant A after the adsorption was completed;

[0048] (3) Cleaning: add NaCl solution with a concentration of 0.9% to the adsorbed resin according to the ratio of material to liquid 1:3, remove the supernatant after shaking and mixing, and repeat cleaning 5 times;

[0049] (4) Elution: Add NaCl solution with a concentration of 5% to the cleaned resin according to the ratio of solid to liquid at 1:3, collect the clear liquid after shaking and eluting for 30 minutes, repeat the operation 5 times, collect all the eluents and mix them evenly to obtain Eluent A;

[00...

Embodiment 2

[0058] (1) Egg liquid pretreatment: Stir the egg white liquid and adjust the pH to 9.5;

[0059] (2) Adsorption by metal chelating cation resin: mix carboxyl-type weak cation exchange resin and pretreated egg white liquid according to the ratio of material to liquid 1:5, add ferric chloride, so that the molar concentration of ferric chloride in the egg white liquid is 0.1mmol / L, adsorbed for 5 hours, and removed the supernatant A after the adsorption was completed;

[0060] (3) Cleaning: add a NaCl solution with a concentration of 0.9% to the adsorbed resin according to the ratio of material to liquid 1:3, remove the supernatant after shaking and mixing, and repeat the cleaning 4 times;

[0061] (4) Elution: Add NaCl solution with a concentration of 7% to the cleaned resin according to the ratio of solid to liquid at 1:3, collect the clear liquid after shaking and eluting for 30 minutes, repeat the operation 4 times, collect all the eluents and mix them evenly to obtain Elue...

Embodiment 3

[0070] (1) Egg liquid pretreatment: Stir the egg white liquid and adjust the pH to 6.5;

[0071] (2) Adsorption by metal chelating cation resin: mix carboxyl type weak cation exchange resin and pretreated egg white liquid according to the ratio of material to liquid 1:5, add ferric chloride, so that the molar concentration of ferric chloride in egg white liquid is 0.2mmol / L, adsorbed for 5 hours, and removed the supernatant A after the adsorption was completed;

[0072] (3) Cleaning: add NaCl solution with a concentration of 0.9% to the adsorbed resin according to the ratio of material to liquid 1:3, remove the supernatant after shaking and mixing, and repeat cleaning 5 times;

[0073] (4) Elution: Add NaCl solution with a concentration of 5% to the cleaned resin according to the ratio of solid to liquid at 1:3, collect the clear liquid after shaking and eluting for 30 minutes, repeat the operation 5 times, collect all the eluents and mix them evenly to obtain Eluent A;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com