Converter sliding plate slag blocking hydraulic control device

A technology of control device and slide plate, which is applied in the direction of fluid pressure actuating device, manufacturing converter, fluid pressure actuating system components, etc. problems, to achieve significant economic benefits, improve quality, and improve the effect of response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

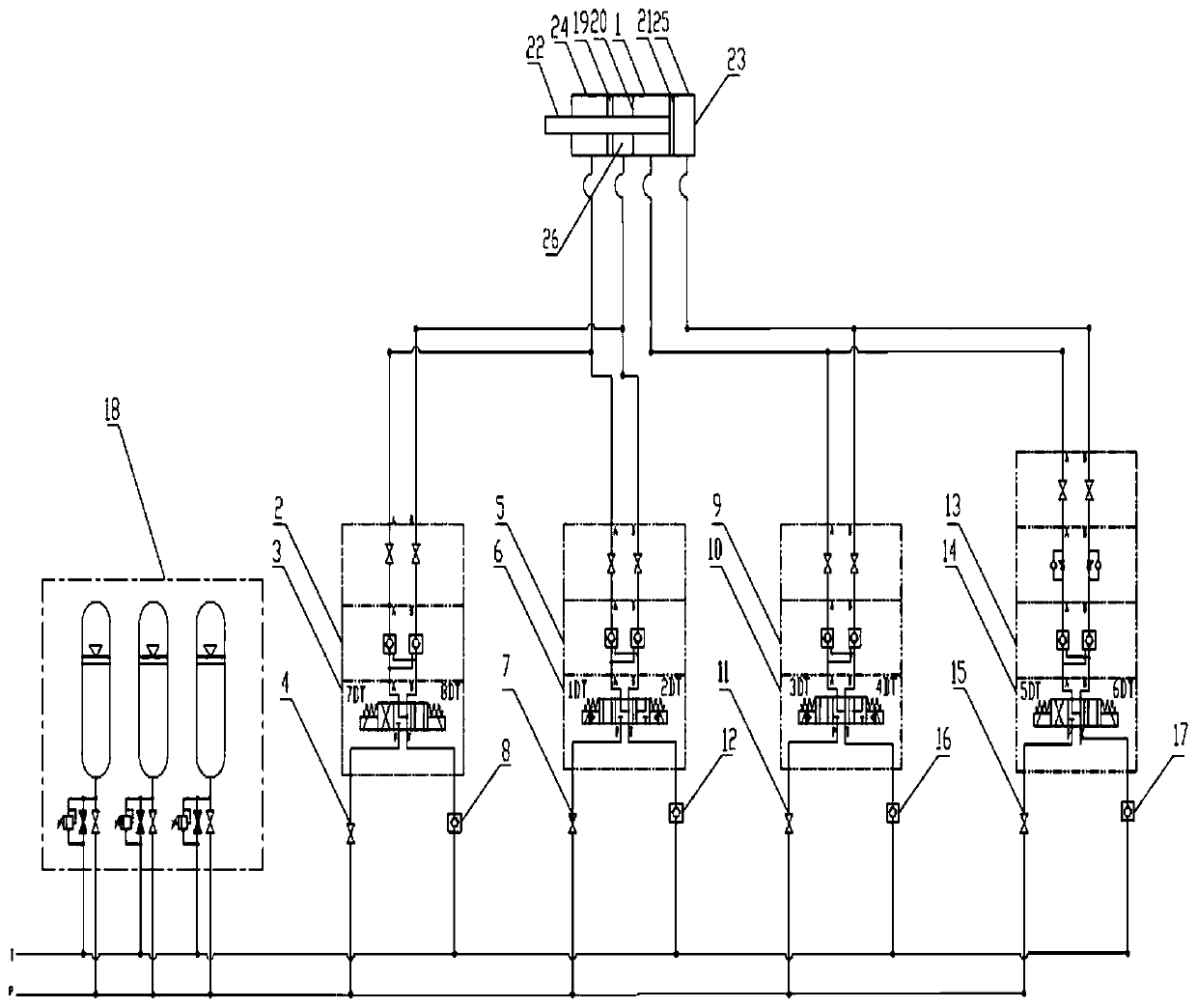

[0017] The present invention includes a composite hydraulic cylinder 1 , a first quick response control unit, a second quick response control unit, a first slow electromagnetic control unit, a second slow electromagnetic control unit and an accumulator group 18 .

[0018] As shown in the figure, the composite hydraulic cylinder 1 is composed of a first hydraulic cylinder 24 and a second hydraulic cylinder 25 . The first hydraulic cylinder 24 is made up of piston rod, cylinder barrel 23, first piston 19, dividing plate 20; The second hydraulic cylinder 25 is made up of piston rod, cylinder barrel 23, dividing plate 20, second piston 21; The first hydraulic cylinder 24 and the second hydraulic cylinder 25 share a piston rod, cylinder barrel 23, and partition 20. In the first hydraulic cylinder 24, the pressure is formed by the outer surface of the first piston 19, cylinder barrel 23, partition 20, and piston rod. Cavity 26.

[0019] As shown in the figure, the overall structure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com