Piezoelectric and electromagnetic coupling vibration sensor

A vibration sensor and electromagnetic coupling technology, applied in the direction of using electromagnetic means, instruments, and electrical devices, can solve the problems of low monitoring sensitivity and inaccurate monitoring results, and achieve the effect of improving resolution, sensitivity and sensitivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

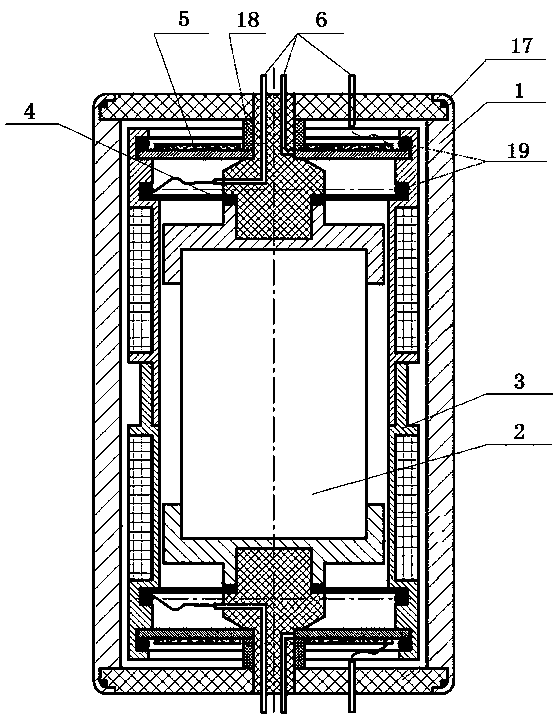

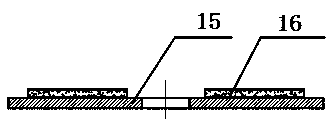

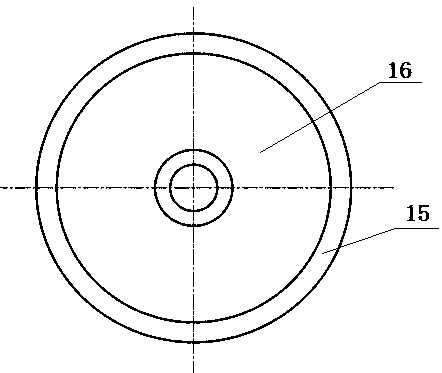

[0026] see Figure 1-Figure 5 A piezoelectric and electromagnetic coupling vibration sensor shown includes an outer casing 1, a magnetic circuit system 2 is arranged in the center of the outer casing 1, and a closed annular gap is formed between the magnetic circuit system 2 and the outer casing 1, and the The annular gap generates a gap magnetic field, and the coil vibrating body 3 is arranged in the annular gap. The coil vibrating body 3 is suspended outside the magnetic circuit system 2 through the spring sheet 4, and a piezoelectric vibrator 5 is arranged between the coil vibrating body 3 and the magnetic circuit system 2. The coil vibrating body 3 can vibrate up and down and reset relative to the magnetic circuit system 2 under the condition of external vibration, and the up and down vibration of the coil vibrating body 3 relative to the magnetic circuit system 2 makes the coil vibrating body 3 cut the gap magnetic field to generate an induced electrical signal, At the sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com