An AC stepping motor

A technology of stepping motors and motor bodies, which is applied in the direction of electromechanical devices, electrical components, electric components, etc., can solve the problems of excessive circular runout tolerance of the motor shaft, loosening and falling off of the fixed part of the motor, and lower production pass rate, etc., to achieve enhanced Air pumping capacity, avoiding the excessive tolerance of motor shaft circular runout, and ensuring the effect of production safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

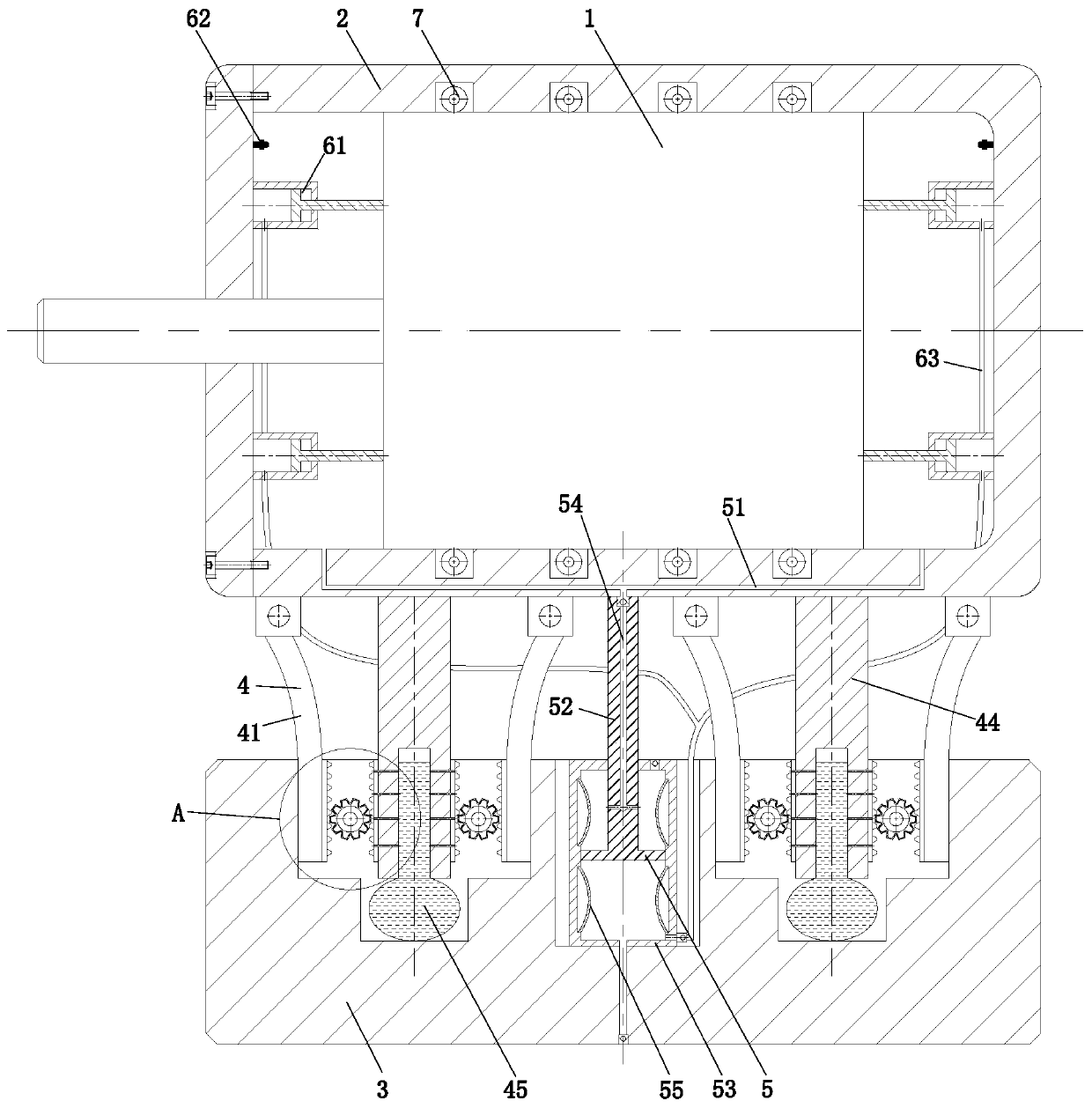

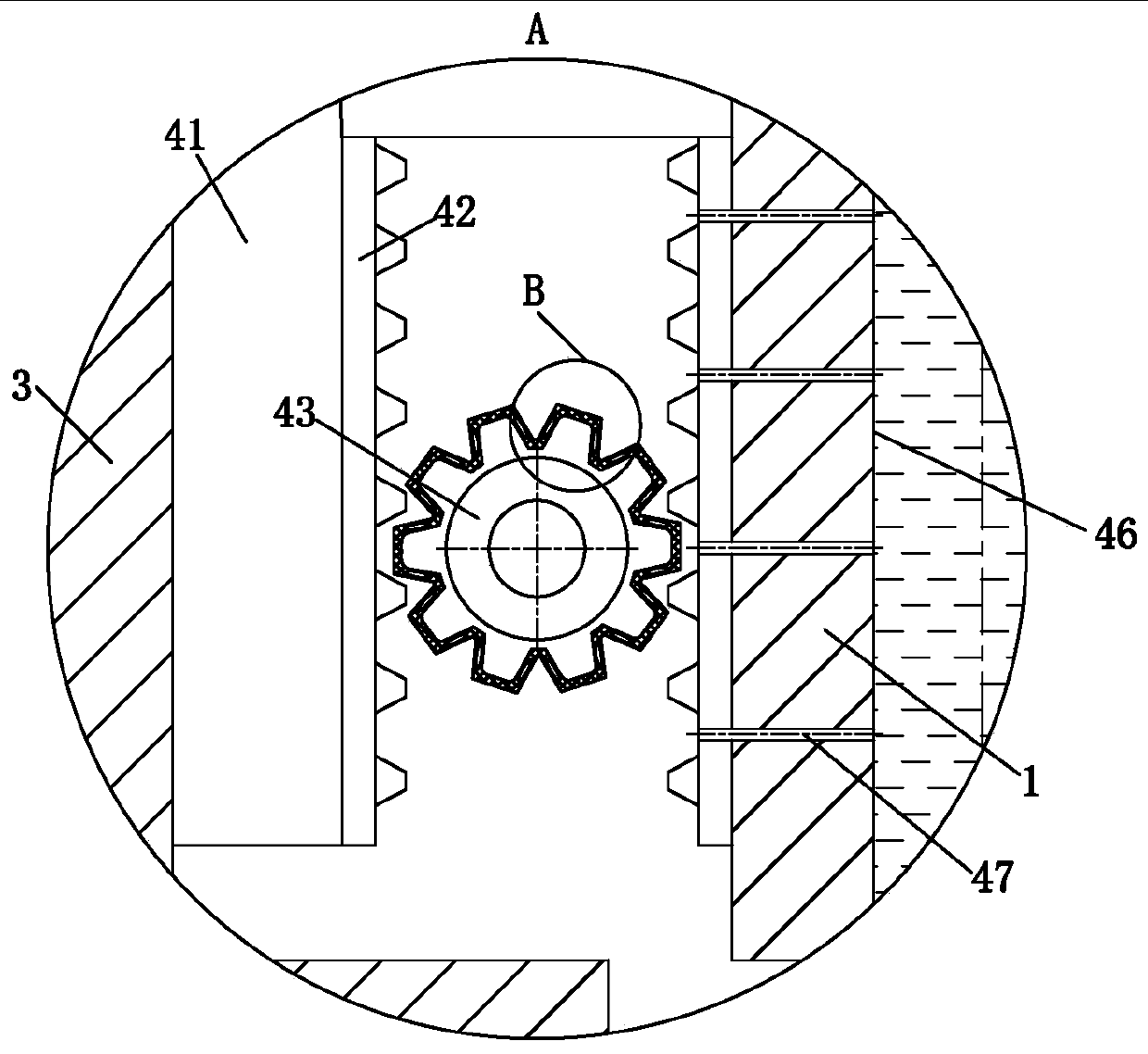

[0023] As an embodiment of the present invention, one end of the support column 44 located in the base 3 is provided with an oil bag 45, and the oil bag 45 is filled with lubricating oil; the end of the support column 44 located in the base 3 is provided with a lubrication hole 46. The oil bladder 45 is in communication with the lubrication hole 46; the lubrication hole 46 and the rack 42 are in communication through a set of communication holes 47; the oil bladder 45, the lubrication hole 46 and the communication hole 47 are mutually matched for Reduce the wear of the gear 43 and the rack 42; the high-frequency vibration generated by the motor body 1 during normal operation is transmitted to the connecting rod 41 and the support column 44 through the soundproof box 2. The support column 44 squeezes the oil sac 45, and the oil sac 45 The lubricating oil is extruded onto the rack 42 through the lubrication hole 46 and the communicating hole 47, so that the gear 43 and the rack ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com