Motor mounting structure with electromagnetic induction type rotary transformer

A resolver and electromagnetic induction technology, applied in electromechanical devices, structural connections, electrical components, etc., can solve the problems of poor shock resistance, poor anti-shake ability, and can only be installed at the end of the motor shaft, achieving long service life and high resistance. The effect of strong low temperature capability and diversified installation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in detail below in conjunction with specific embodiments. The following examples will help those skilled in the art to further understand the present invention, but do not limit the present invention in any form. It should be pointed out that for those of ordinary skill in the art, several changes and modifications can be made without departing from the concept of the present invention.

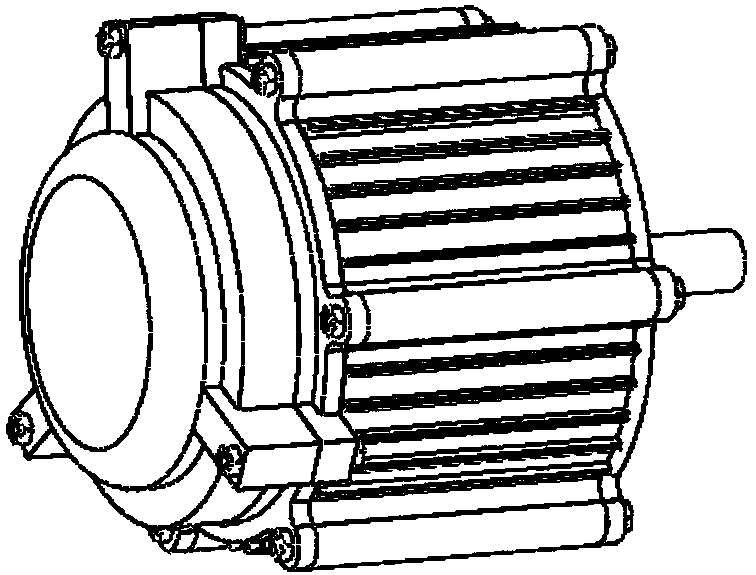

[0042] figure 1 It is a schematic diagram of the appearance of the inner rotor motor of the present invention.

[0043] The inner rotor motor uses the wire package in the middle of the motor as a rotating body to output torque, and the magnetic steel of the motor is fixed differently.

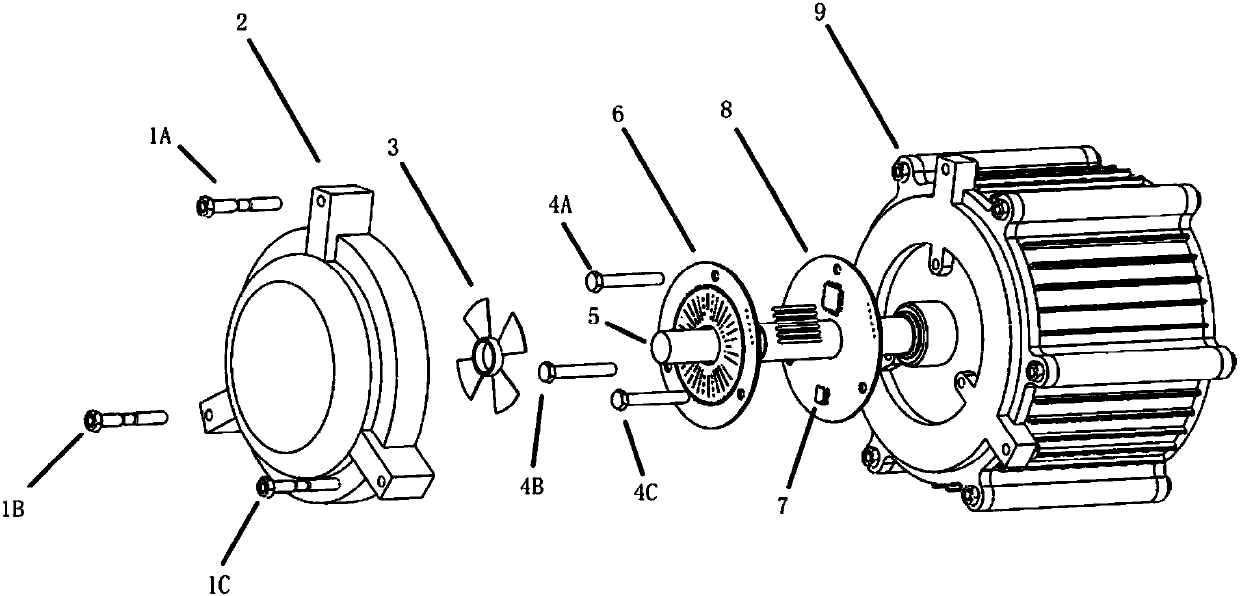

[0044] figure 2 It is a schematic diagram of the explosive structure of the inner rotor motor of the present invention.

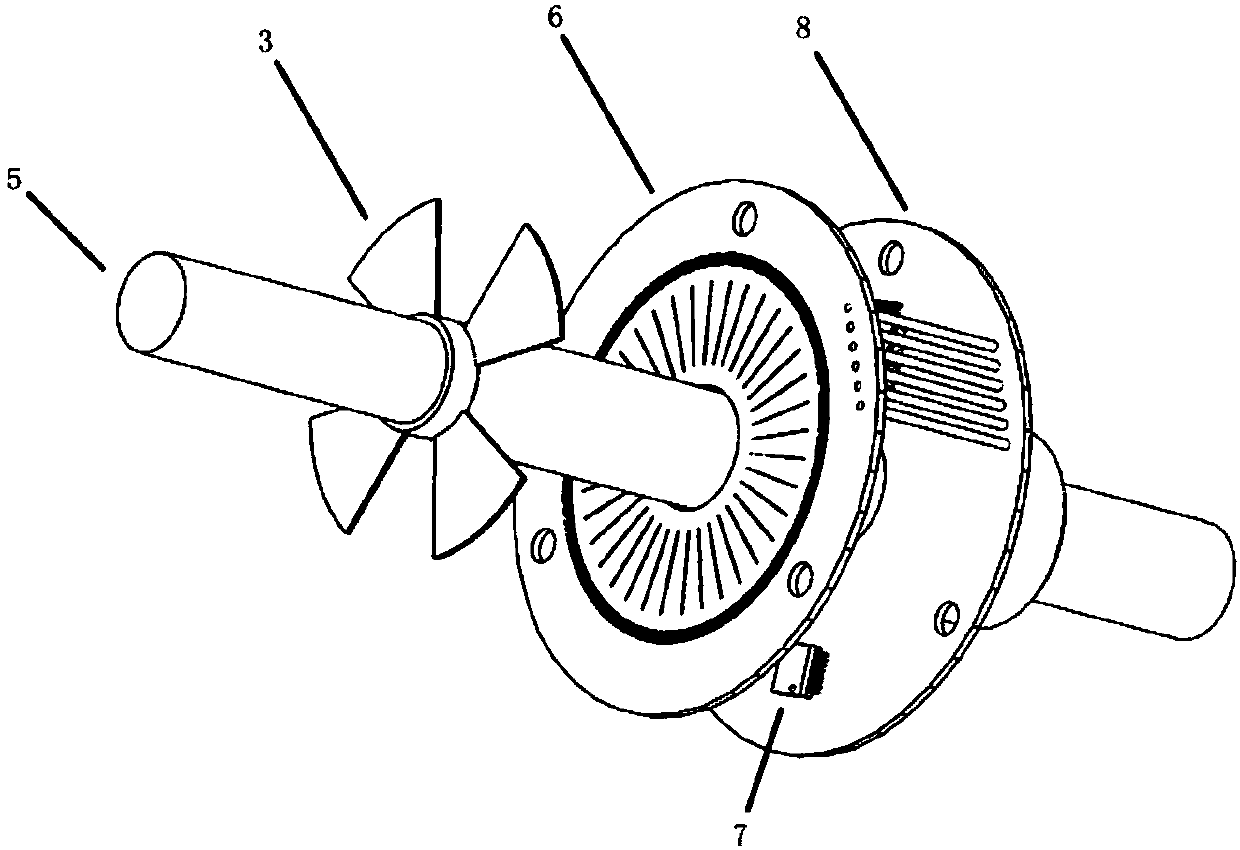

[0045] As shown in the figure, the wire package in the middle of the motor body 9 is connected to the motor shaft 5 and drives it to rotate; the sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com