Coal gasification catalyst loading method

A catalyst and coal gasification technology, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, catalyst activation/preparation, etc., can solve the problems of coal sample sticking to the wall, blocking equipment, etc., reduce the probability of agglomeration, and avoid coal sample Effects of wall sticking and clogged equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to further understand the present invention, the preferred embodiments of the present invention are described below in conjunction with the examples, but it should be understood that these descriptions are only for further illustrating the features and advantages of the present invention rather than limiting the patent requirements of the present invention.

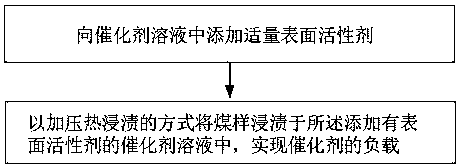

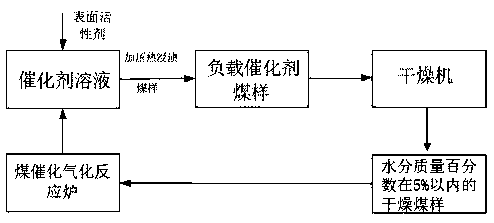

[0021] refer to figure 1 , the invention provides a catalyst loading method for coal gasification, comprising the following steps:

[0022] Step 1, adding an appropriate amount of surfactant to the catalyst solution.

[0023] Specifically, the catalyst solution used in this embodiment can be alkali metal potassium or sodium salts and hydroxides, such as potassium carbonate solution; or alkaline earth metal calcium, magnesium salts or hydroxides, transition metal iron, Salts of nickel, or binary, ternary or multiple composite catalysts of the above metals. Because the catalyst loading in the coal sample i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com