splash deflector

A diversion device and anti-splash technology, which is applied in the direction of metal processing equipment, maintenance and safety accessories, metal processing machinery parts, etc., can solve the problem that cooling water is easy to splash out of the water tank, so as to avoid splashing out of the water tank, ensure cleanliness, easy to get effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

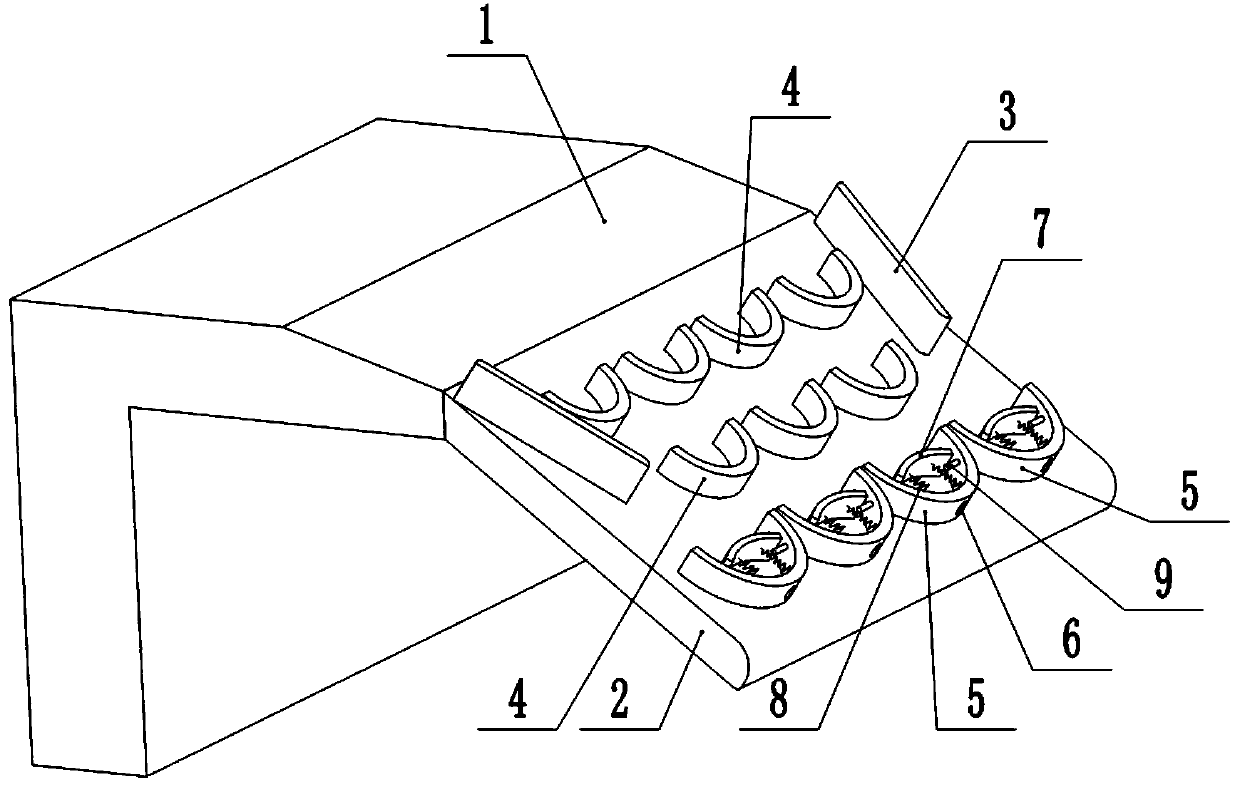

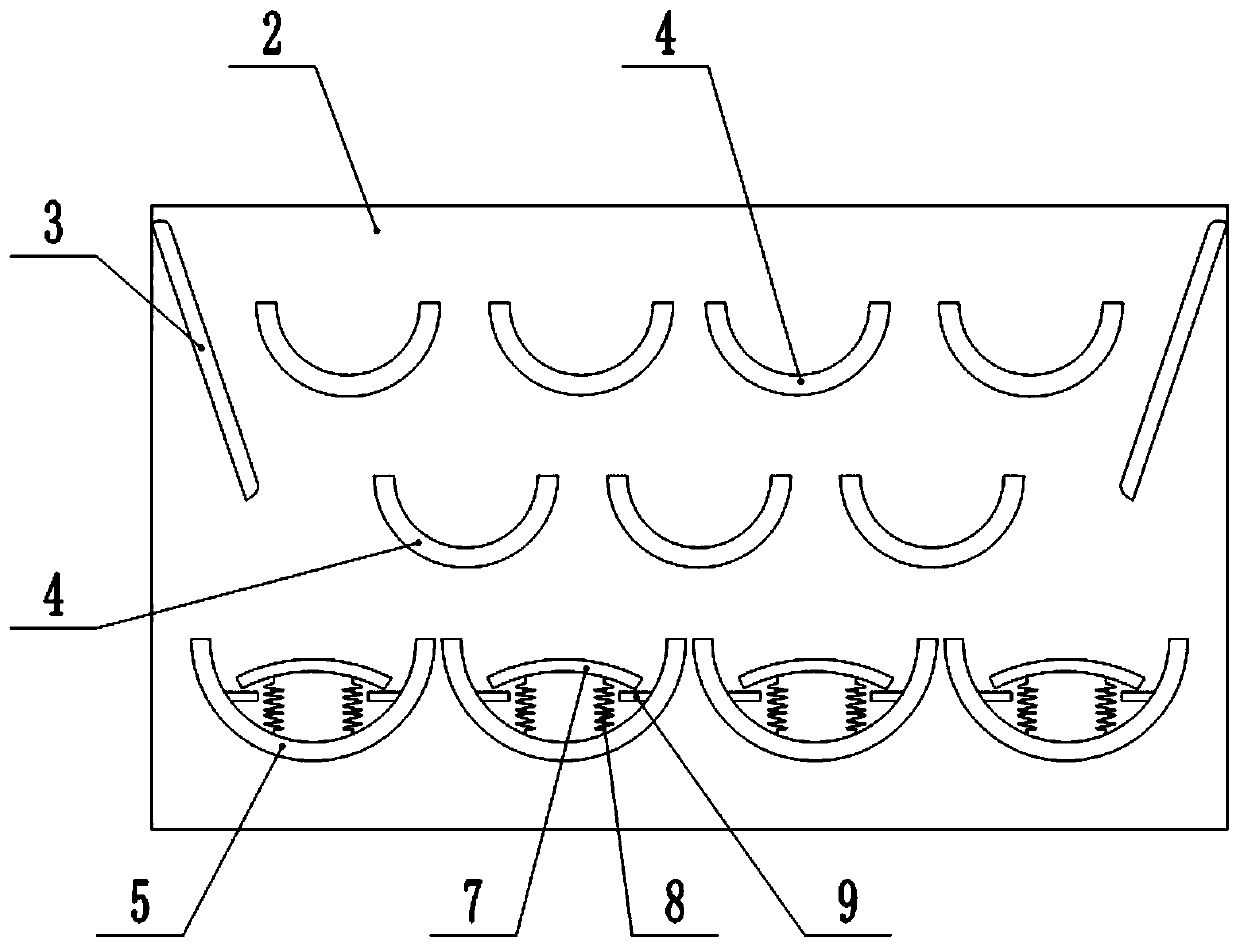

[0036] This embodiment is basically as figure 1 and figure 2 As shown, the anti-splash deflector includes a deflector 2 fixedly connected to the right end of the self-flowing part 1 at the low point of cooling water, the deflector 2 is arranged obliquely, and the left end of the deflector 2 is higher than the right end. The inclination angle of flow plate 2 is 45°. The side wall of the deflector 2 is provided with two deflectors 3 and several spoilers 4, the two deflectors 3 are in an inverted figure-eight shape, and the spoilers 4 are arc-shaped. In this embodiment, the number of baffles 4 is seven, and the seven baffles 4 are divided into upper and lower layers. The quantity of 4 is four, and the quantity of the spoiler 4 of the lower floor is three.

[0037] Below the two ends of the diversion plate 3 and the lower baffle 4 are provided with an arc-shaped diverter plate 5, the diverter plate 5 is fixedly connected to the diverter plate 2, and the diverter plate 5 is use...

Embodiment 2

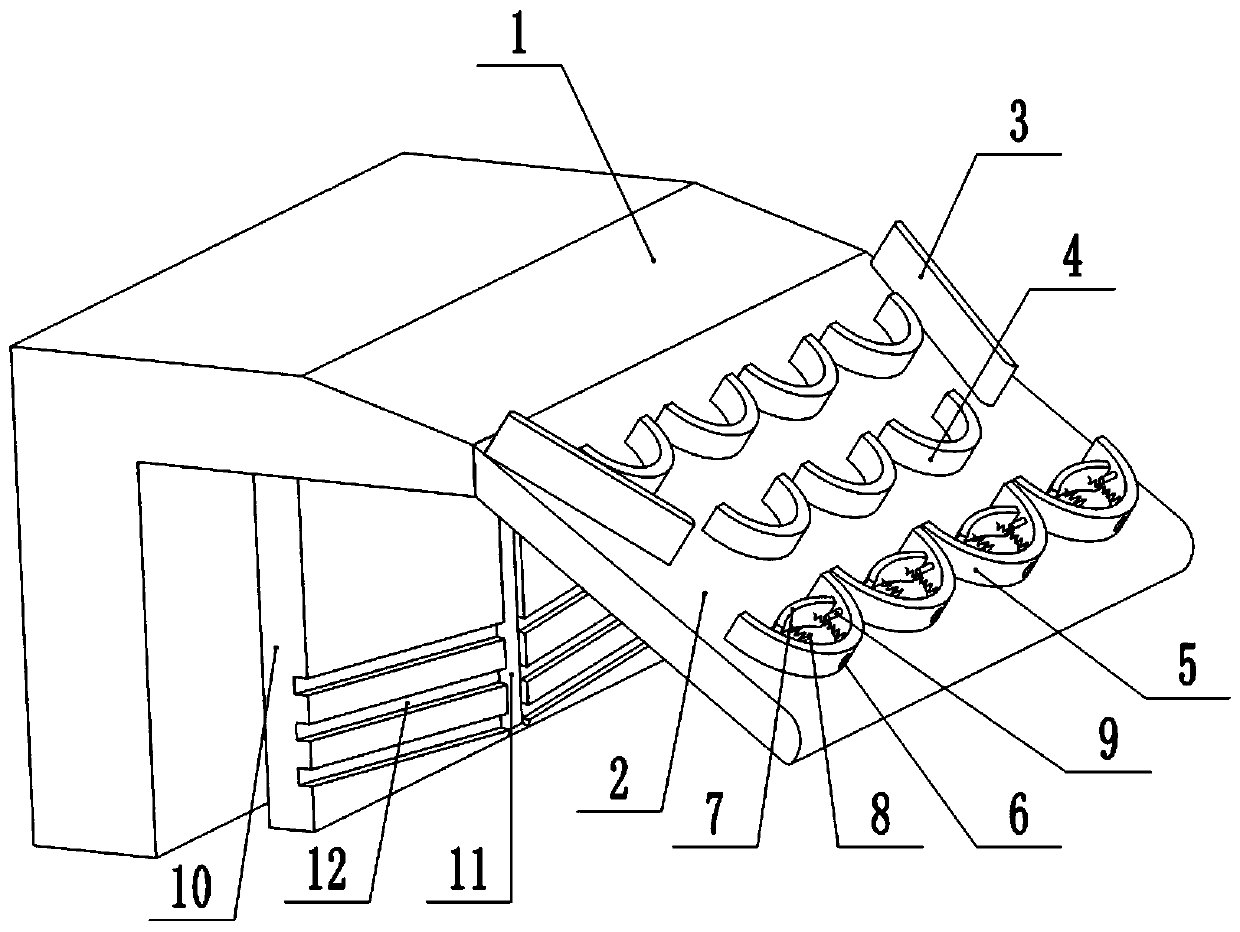

[0042] The difference between this embodiment and Embodiment 1 is that: figure 2 and image 3 As shown, the splash-proof deflector device further includes a splash-proof plate 10 , which is located on the left side of the deflector 2 , and the splash-proof plate 10 is fixedly connected with the cooling water low point artesian part 1 . A confluence groove 11 and a plurality of drainage grooves 12 are provided on the right side wall of the splash guard 10. In this embodiment, there are six drainage grooves 12 in total. The confluence groove 11 is vertically arranged and the confluence groove 11 is located at the center of the splash guard 10, the diversion groove 12 is connected with the confluence groove 11, and the diversion groove 12 is arranged symmetrically along the vertical center line of the confluence groove 11, and the diversion groove 12 is close to One end of the confluence groove 11 is lower than the end of the drainage groove 12 away from the confluence groove 1...

Embodiment 3

[0045] The difference between this embodiment and Embodiment 1 is that: figure 2 , Figure 4 and Figure 5 As shown, the splash-proof deflector device further includes a splash-proof plate 10 , which is located on the left side of the deflector 2 , and the splash-proof plate 10 is fixedly connected with the cooling water low point artesian part 1 . The bottom end of the splash guard 10 is a V-shaped structure, and the splash guard 10 is provided with a first splash roller 13 and a second splash roller 14 arranged symmetrically along the vertical center line of the splash guard 10, and the first splash roller 13 and the outer walls of the second anti-splash roller 14 are in contact with the V-shaped surface of the splash-proof plate 10, and the ends of the first anti-splash roller 13 and the second anti-splash roller 14 that are close to each other are inclined downward. Specifically, a mounting block 15 is fixedly connected to the side wall and the V-shaped surface of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com