Step-by-step dressing cutting device

A step-by-step, frame technology, applied in metal processing and other directions, can solve the problems of uneven cutting, inconvenient division of large pieces of dressing, and large manual labor, achieving ingenious structure, reducing manual labor, and improving cutting efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

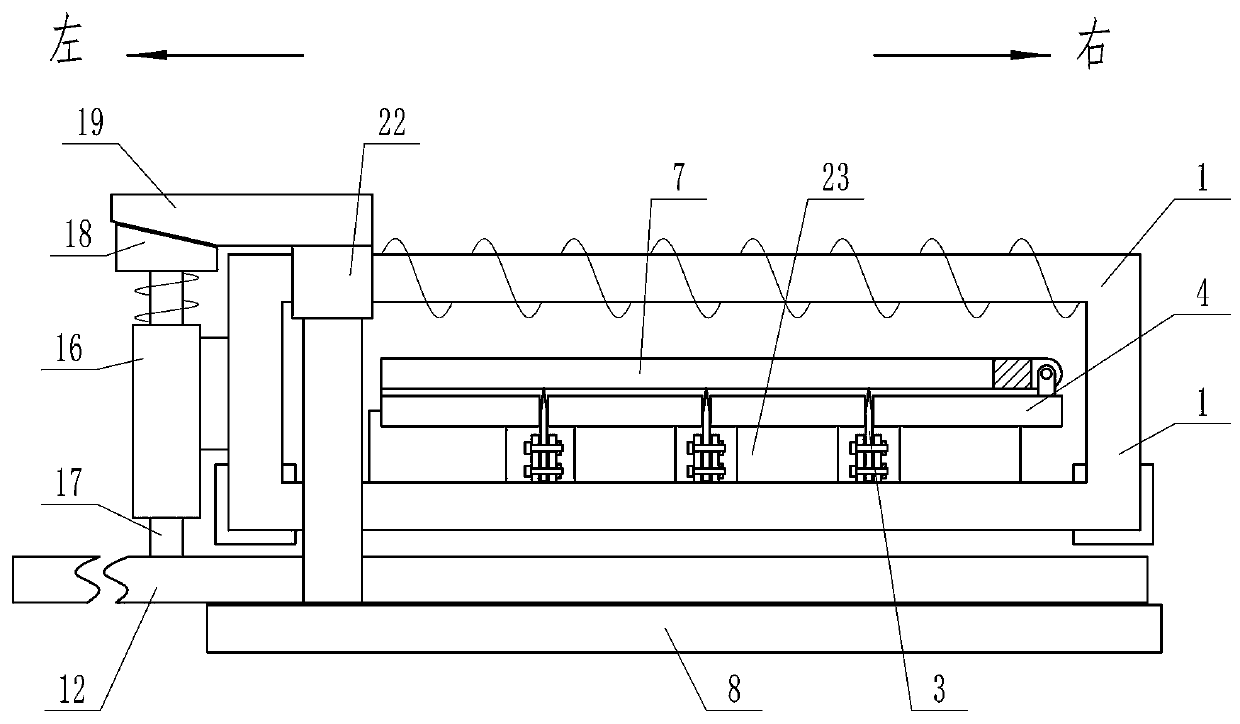

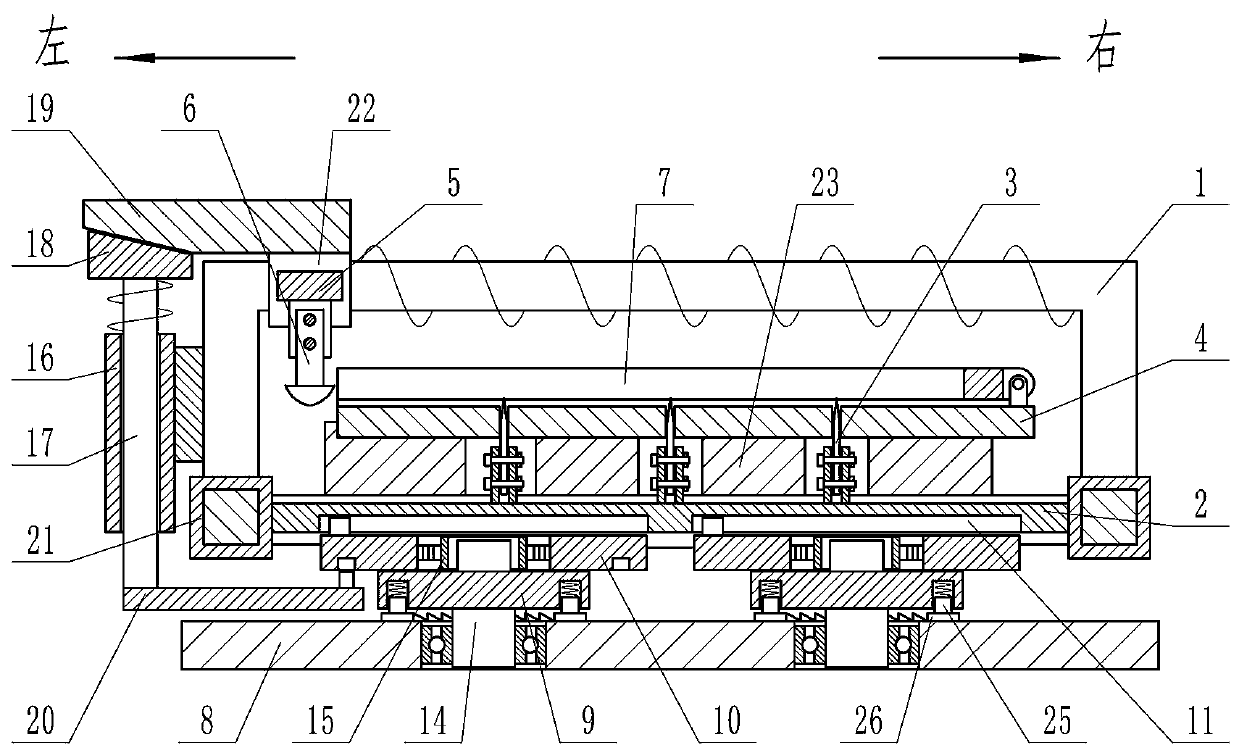

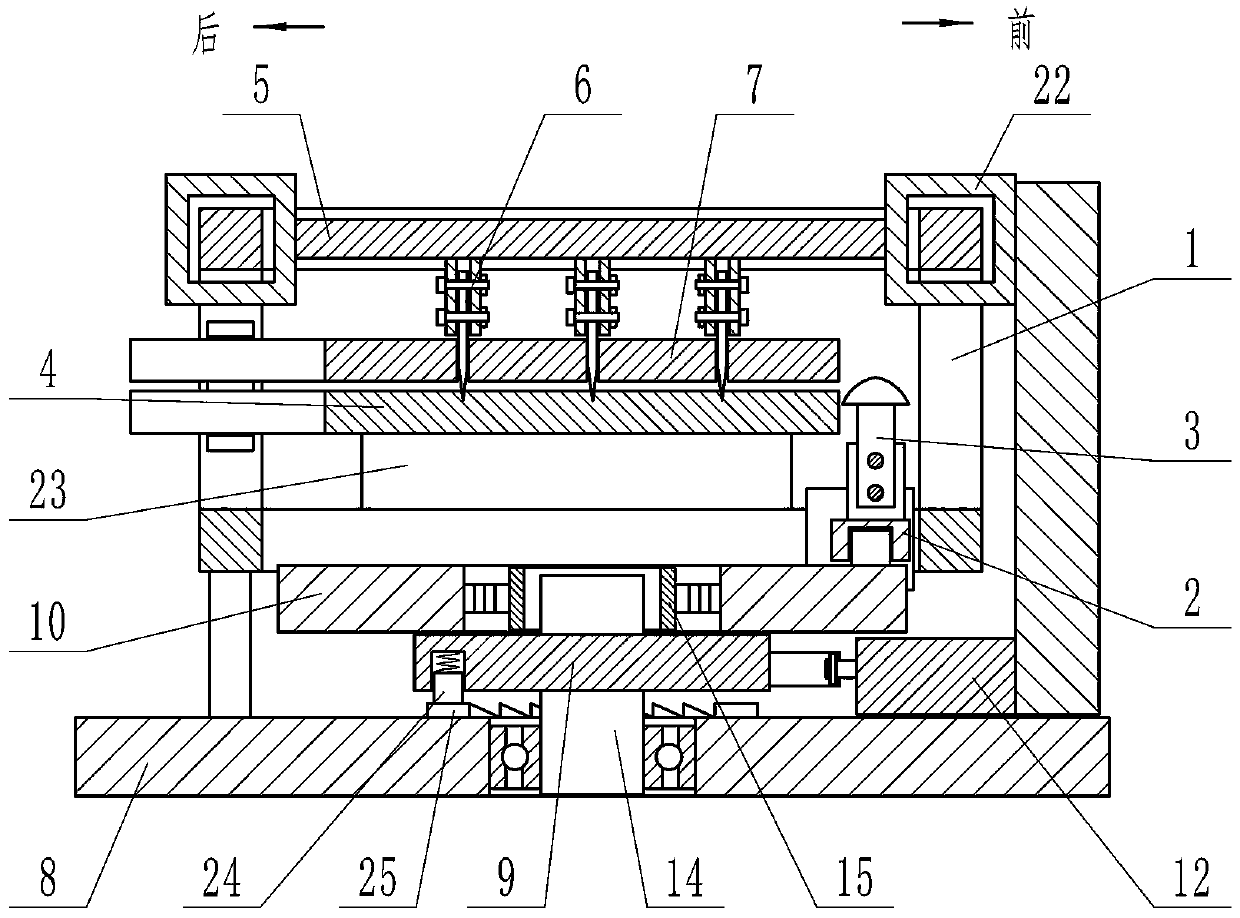

[0026] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0027] Depend on Figure 1 to Figure 13 Given, the present invention comprises a horizontal cuboid frame 1, the lower end of the frame 1 has a horizontal plate 2 arranged along the left and right directions and can move back and forth along the frame 1, and a plurality of first horizontal plates uniformly distributed along the left and right directions are fixed on the upper end surface of the horizontal plate 2. A blade 3, a horizontal and detachable flat plate 4 is installed in the frame 1, a plurality of first through grooves are opened along the front and rear directions and vertically run through the upper and lower end surfaces of the flat plate 4 on the flat plate 4, and the plurality of first through grooves are connected with the plurality of first through grooves. There is a one-to-one correspondence between th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com