External screw thread hot extrusion molding machine for fire extinguisher siphon pipe

A technology of external thread and siphon pipe is applied in the field of external thread hot extrusion forming machine for siphon pipe of fire extinguisher, which can solve the problems of low efficiency and complicated process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

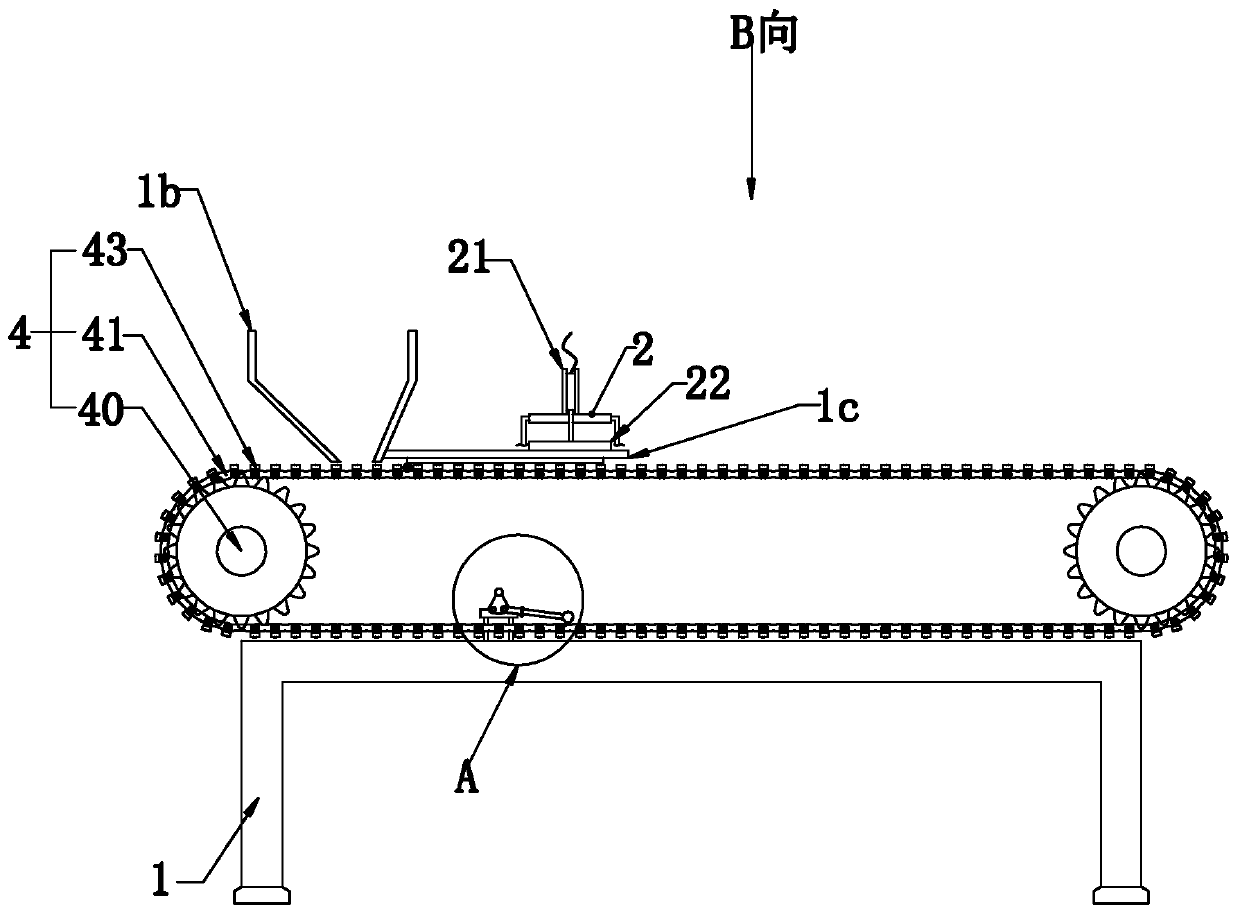

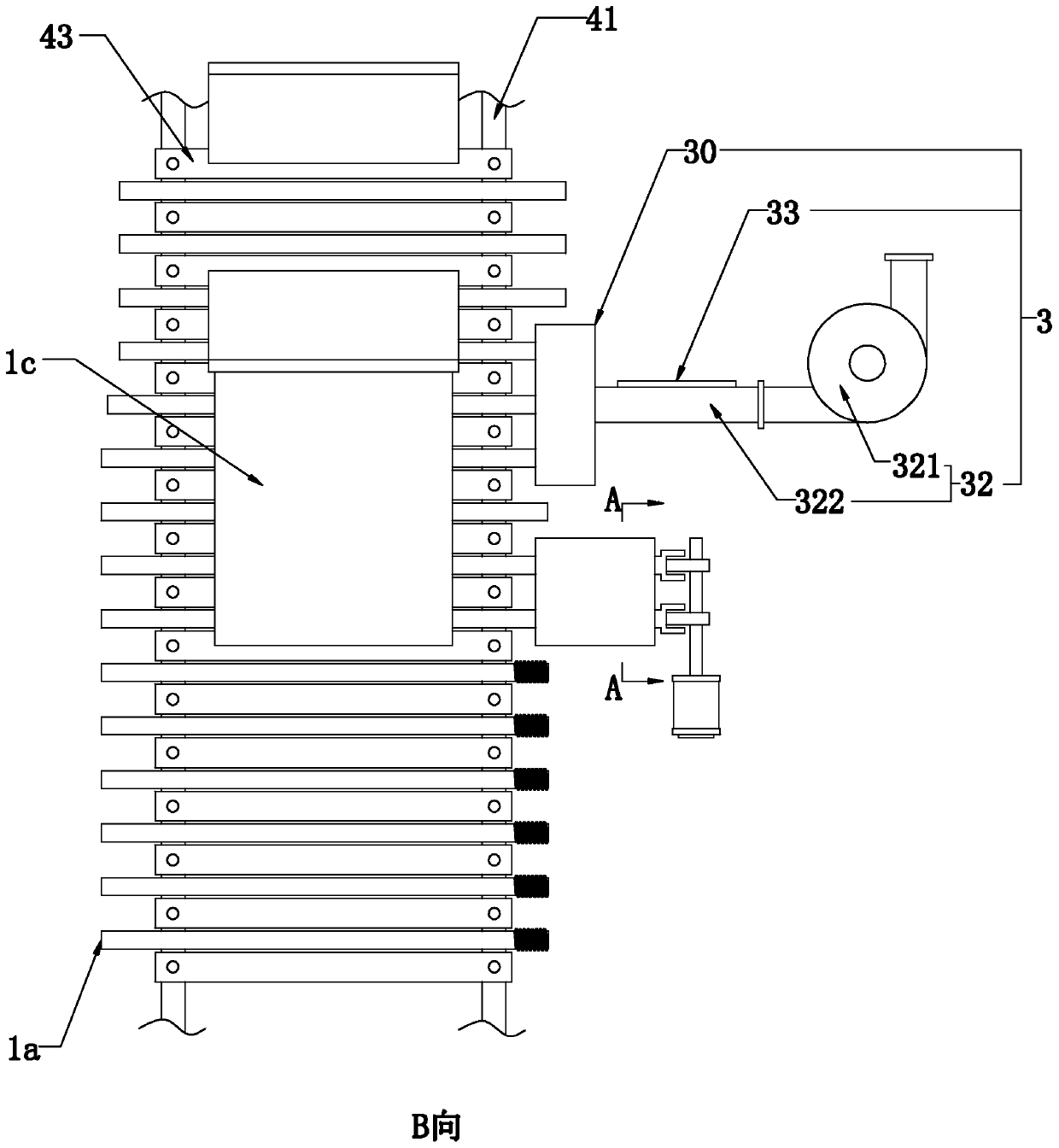

[0028] like Figure 1 to Figure 7 As shown, the present invention discloses an external thread hot extrusion molding machine for a fire extinguisher siphon, which includes a frame 1, and in a specific embodiment of the present invention, includes a screw thread installed on the frame 1 and used to extrude a plastic pipe joint Forming component 2, preheating component 3 for heating plastic pipe joints, and conveying component 4 for combing plastic tubes and feeding them into preheating component 3 for heating and thread forming component 2 for thread forming .

[0029] In a specific embodiment of the present invention, the conveying assembly 4 can convey two plastic pipes into the thread forming assembly 2 at a time.

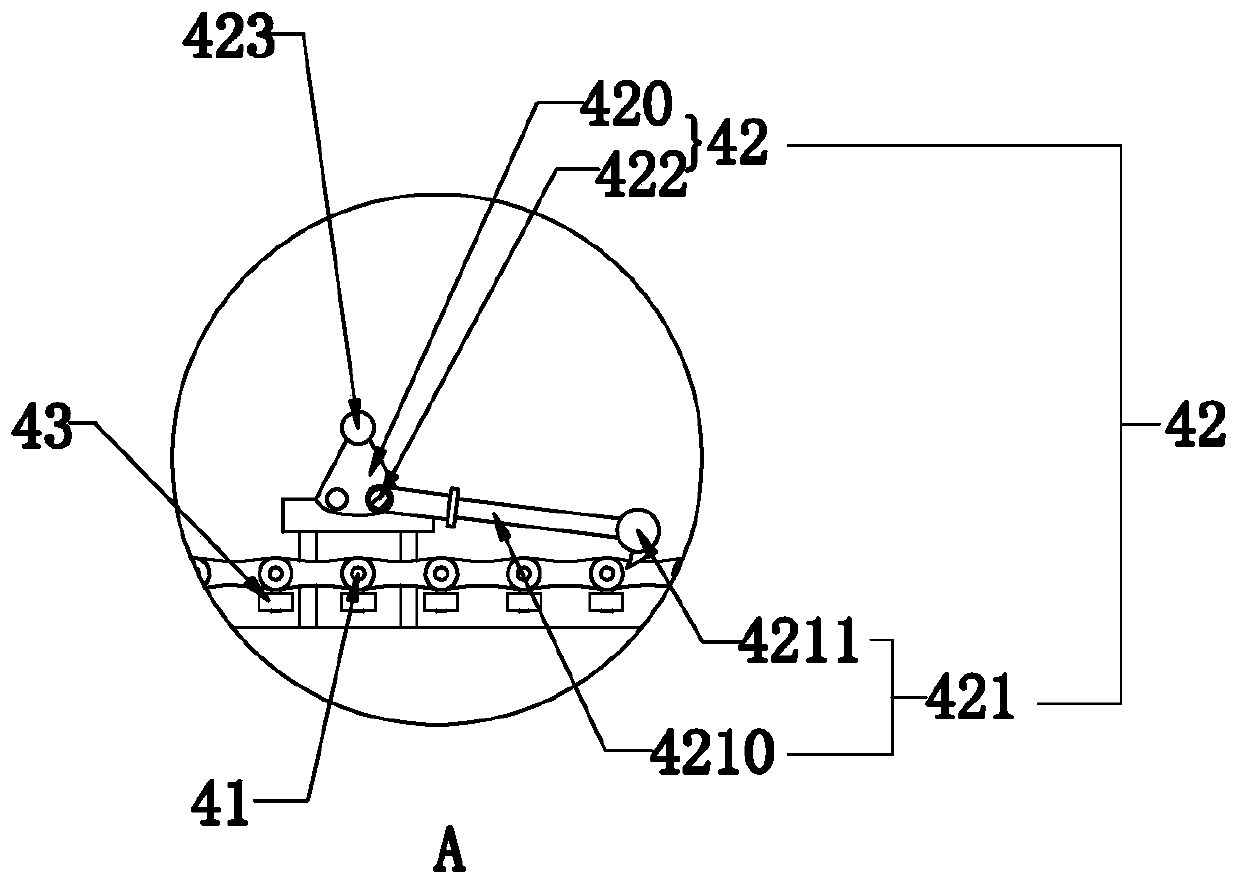

[0030] In a specific embodiment of the present invention, the conveying assembly 4 includes at least two groups of transmission sprockets 40 rotatably connected to the frame 1, transmission chains 41 laid on and engaged with each group of transmission sprockets ...

Embodiment 2

[0054] Embodiment 2, the difference with embodiment 1 is that

[0055] like Figure 8 As shown, in the specific embodiment of the present invention, it also includes a limiting device 5 for limiting the movement of the transmission chain 41 at intervals; ) the limit block 51 inside.

[0056] By adopting the above technical solution: when the plastic pipe is being shaped (that is: one end of the plastic pipe is in the thread forming assembly), in order to prevent the transmission chain from moving (for example: due to equipment failure), the transmission chain can be snapped into the transmission chain through the limit block In the chain ring, it can achieve the effect of limiting the transmission chain and ensure the efficiency of production.

Embodiment 3

[0057] Embodiment 3, the difference with the foregoing embodiment is that

[0058] like Figure 9 , in a specific embodiment of the present invention, a layer of heat transfer plate 6 for transferring the internal heat of the hot air pipe 322 to the plastic pipe joint is provided in the bottom of the preheating tank 300 .

[0059] In a specific embodiment of the present invention, the thickness of the heat transfer plate 6 can gradually become thicker from the conveying direction of the conveying assembly.

[0060] In a specific embodiment of the present invention, the heat transfer plate 6 may be provided with a hot gas discharge channel 60 that passes through the heat transfer plate 6 from the direction of the conveying assembly and communicates with the hot air pipe 322 .

[0061] By adopting the above technical solution: the heat transfer plate can not only ensure that the joints of the plastic pipes are softened due to heat, but also avoid blowing the plastic pipes due t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com