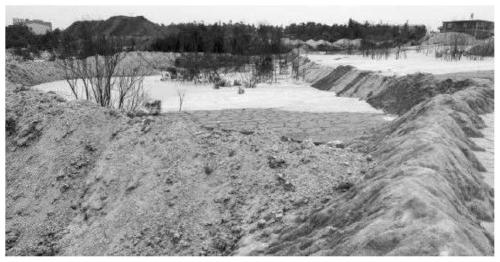

Mixed mortar with high content of stone powder paste

A technology for mixing mortar and gypsum gypsum, which is applied in the field of comprehensive utilization of gypsum powder and gypsum to achieve the effects of good fluidity, stable performance and reduced labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

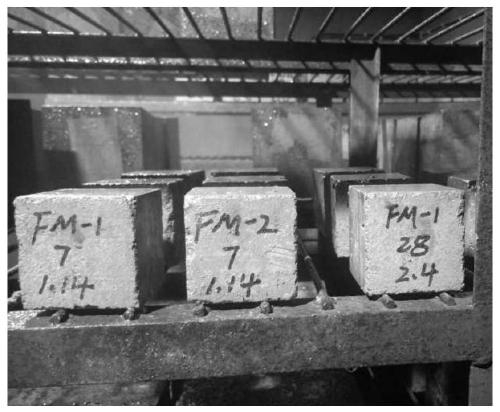

Examples

Embodiment 1

[0032] In the prior art, when mixing mortar and concrete, an appropriate amount of effective fine particles, generally about 25% of fly ash, is added to replace part of the sand and cement with the same amount of fly ash to improve the performance of the mixture. The principle is to make use of the activity of the mixed fly ash to allow the cement to effectively combine and react with fillers, admixtures, etc. during the mixing and hydration solidification process to produce a mixture with better workability and compactness. However, if the amount of effective fine particles in mortar and concrete is too much, it is easy to form powder coating on the surface of aggregate, cause retardation, increase shrinkage, weaken the effect of aggregate skeleton, and affect the compressive and flexural strength of concrete. While the early strength of the mixture increases, it will affect the later strength of the mixture. The present invention mainly utilizes the recycled stone powder pas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com