Water-soluble lignin base chain transferring agent and preparation method thereof

A water-soluble lignin and chain transfer agent technology, which is applied in the field of polymer material science and application, can solve the problems of limited practical application, poor water solubility, and few high-active sites, and achieve good polymerization controllability and harsh reaction conditions , easy operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

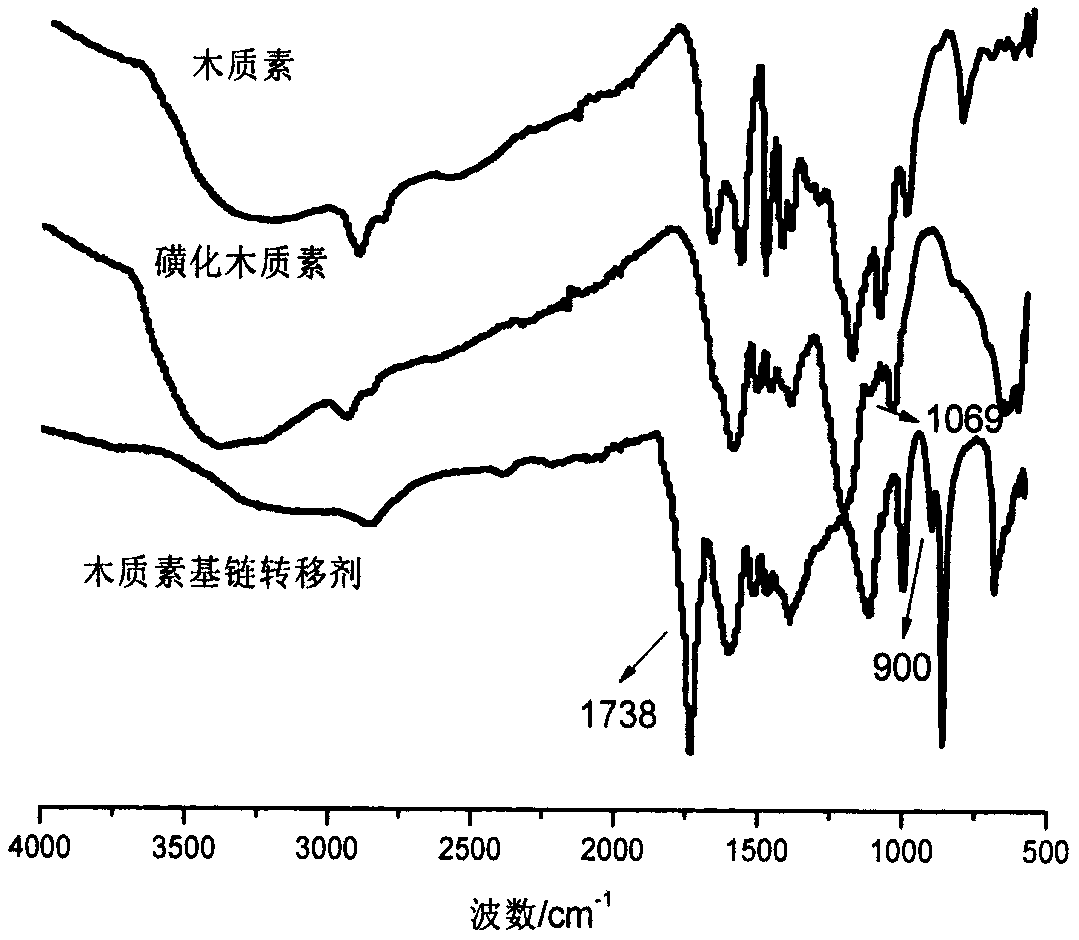

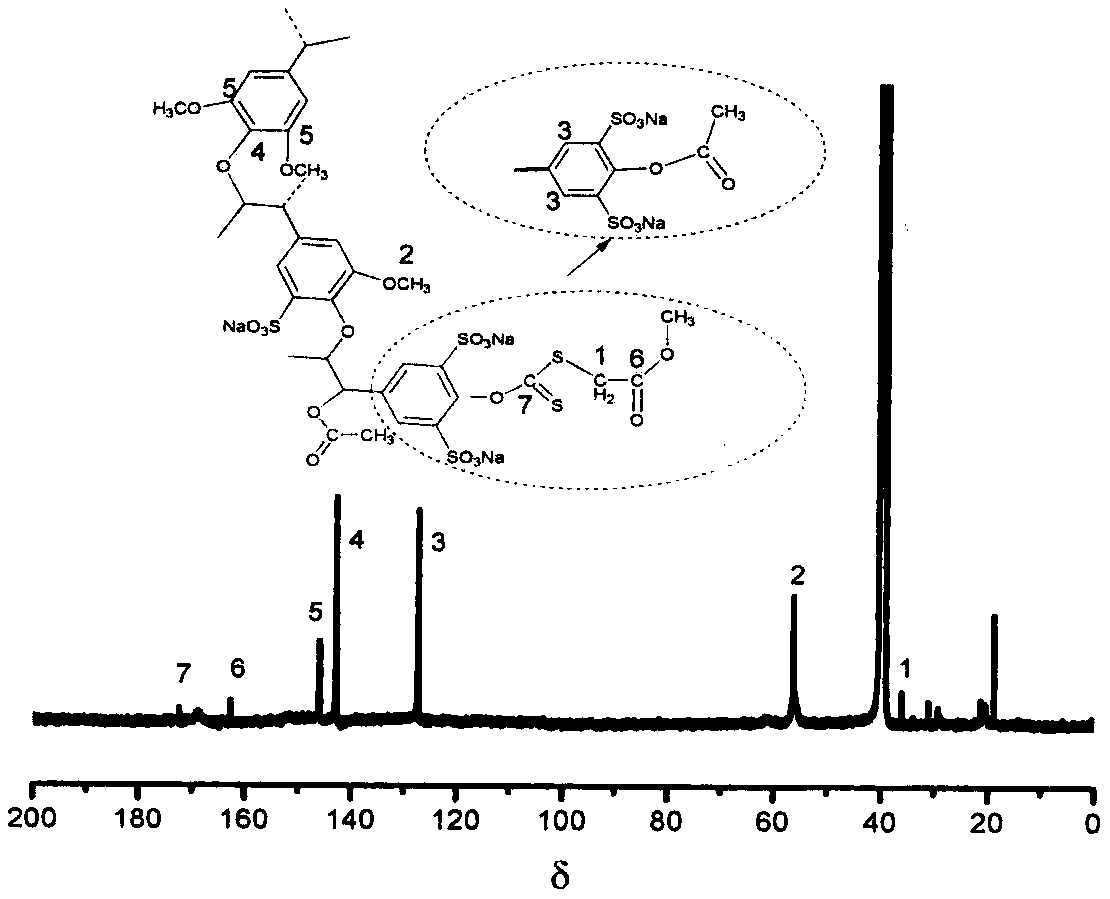

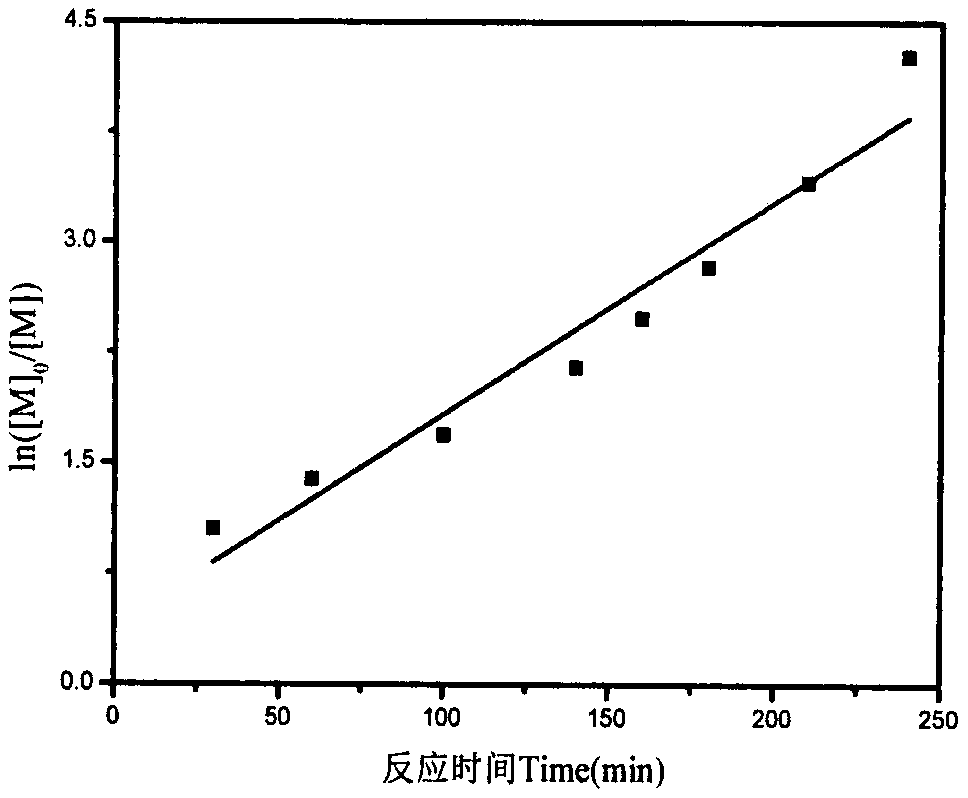

[0019] Example 1 Preparation of water-soluble lignin-based chain transfer agent

[0020] Weigh 1g of lignin and 15mL of chloroform in a reaction flask, stir well, add 1g of chlorosulfonic acid to react for 2h, add NaOH solution to the system to adjust to pH>7, continue to react for 1h, add HCl solution to adjust the system pH to Neutral, the obtained mixed solution was dialyzed for 48 hours, and then freeze-dried to obtain a sulfonated lignin sample.

[0021] Put 1g of the above-obtained sulfonated lignin and 30mL of 1M NaOH solution in the reaction flask, stir to dissolve, and add 1.62g CS dropwise to the flask in an ice water bath 2 After reacting at 30℃ for 4h, add 1.83g methyl bromoacetate dropwise, continue the reaction for 12h, drop the reaction solution into anhydrous ethanol for precipitation, the resulting precipitate is dissolved in deionized water and then dropped into anhydrous ethanol for precipitation, repeat operation 2 ~3 times, the precipitate is dried to a constan...

Embodiment 2

[0022] Example 2 Preparation of water-soluble lignin-based chain transfer agent

[0023] Weigh 1g of lignin and 15mL of chloroform in a reaction flask, stir well, add 2g of chlorosulfonic acid to react for 2h, add NaOH solution to the system to adjust to pH>7, continue the reaction for 1h, add HCl solution to adjust the system pH to Neutral, the obtained mixed solution was dialyzed for 48 hours, and then freeze-dried to obtain a sulfonated lignin sample.

[0024] Put 1g of the above-obtained sulfonated lignin and 30mL of 1M NaOH solution in the reaction flask, stir to dissolve, and add 1.62g CS dropwise to the flask in an ice water bath 2 After reacting at 30℃ for 4h, add 1.83g methyl bromoacetate dropwise, continue the reaction for 12h, drop the reaction solution into anhydrous ethanol for precipitation, the resulting precipitate is dissolved in deionized water and then dropped into anhydrous ethanol for precipitation, repeat operation 2 ~3 times, the precipitate is dried to a con...

Embodiment 3

[0025] Example 3 Preparation of water-soluble lignin-based chain transfer agent

[0026] Weigh 1g of lignin and 15mL of chloroform in a reaction flask, stir well, add 3g of chlorosulfonic acid to react for 3h, add NaOH solution to the system to adjust to pH>7, continue to react for 2h, add HCl solution to adjust the system pH to Neutral, the obtained mixed solution was dialyzed for 48 hours, and then freeze-dried to obtain a sulfonated lignin sample.

[0027] Put 1g of the above-obtained sulfonated lignin and 30mL of 1M NaOH solution in the reaction flask, stir to dissolve, and add 1.62g CS dropwise to the flask in an ice water bath 2 After reacting at 30℃ for 4h, add 1.83g methyl bromoacetate dropwise, continue the reaction for 12h, drop the reaction solution into anhydrous ethanol for precipitation, the resulting precipitate is dissolved in deionized water and then dropped into anhydrous ethanol for precipitation, repeat operation 2 ~3 times, the precipitate is dried to a constan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com