Sludge ceramsite concrete ecological revetment construction method

A technology of silt ceramsite and construction method, applied in the fields of botanical equipment and methods, excavation, plant protection, etc., can solve the problems of high water content, low shear strength, high compressibility, etc., to improve ecology and beautify the environment, Satisfy the effect of safety and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

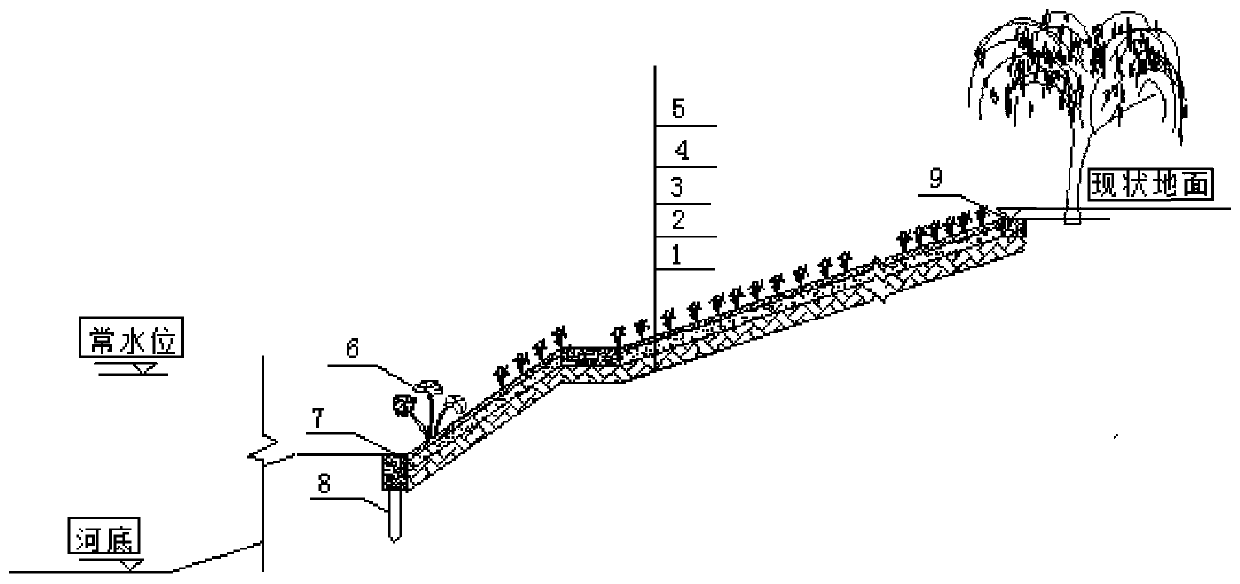

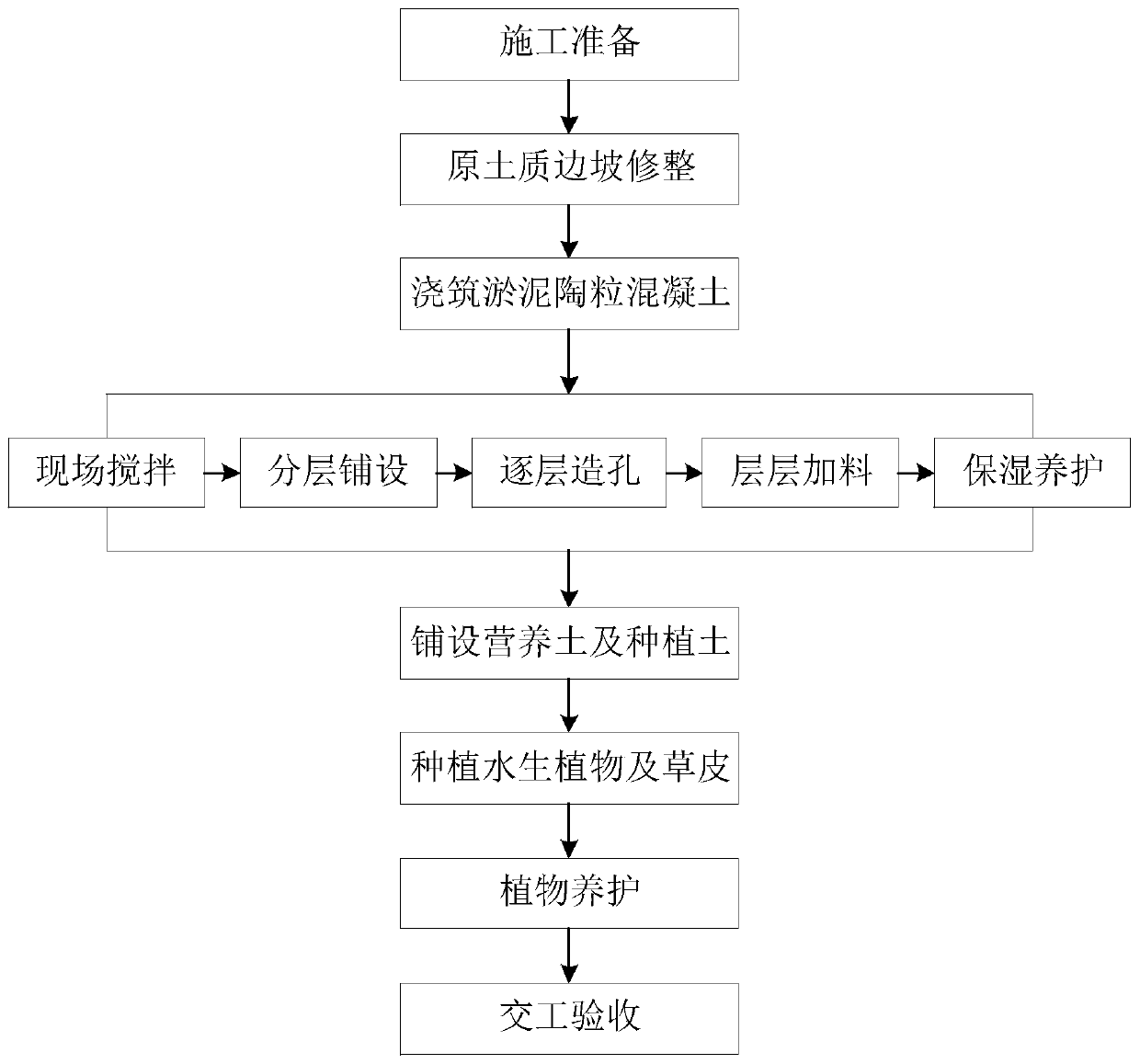

[0030] A kind of silt ceramsite concrete ecological slope protection construction method, such as figure 1 and figure 2 shown, including the following steps:

[0031] The first step, undisturbed soil slope 1 trimming and slope cutting

[0032] The sundries on the surface of the original soil slope 1 are removed, and the original soil slope 1 is trimmed, slope cut, and compacted according to the slope ratio and structural requirements for forming slope protection.

[0033] The second step, pouring silt ceramsite concrete 2

[0034] According to the needs, pour the bottom beam 7 at the foot of the slope and set up wooden piles 8 to protect the bottom of the silt ceramsite concrete ecological slope protection, excavate a certain depth of foundation soil at the top of the slope, and pour silt ceramsite concrete as the roof protection structure, Form the top beam 9.

[0035] A 12cm-thick silt ceramsite concrete 2 is poured on the slope after slope protection. The cast-in-place...

Embodiment 2

[0044]The difference between this embodiment and Embodiment 1 is that in the second step, the silt ceramsite concrete 2 is laid in layers on the slope to be treated, and each layer of silt ceramsite concrete is inserted and rammed to form and make holes. And the matrix balls are filled into the holes of each layer of silt ceramsite concrete, which can not only serve as the soil required for plant growth, but also provide the required fertilizer for plant growth. After the matrix balls are pulverized, connected pores can be formed between the matrix balls, which further meets the requirements of the pores for good plant growth. The matrix ball is a spheroid made by mixing soil, slow-release fertilizer, organic matter, and water-retaining materials. The particle size is 5mm to 10mm. Organic matter 3%, water-retaining material 3%. The preparation process of the matrix ball is as follows: mix the soil, slow-release fertilizer, organic matter, and water-retaining materials accordi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com