Bar-planting-type greening groove structure of roadbed slope platform and mounting method

A technology of greening tanks and platforms, applied in botany equipment and methods, infrastructure engineering, excavation, etc., can solve the problems of difficult to guarantee the quality of greening tank concrete maintenance, low survival rate of plant cultivation in greening tanks, and non-replaceable maintenance of greening tanks and other issues, to achieve the effect of saving engineering construction costs, improving construction efficiency, and facilitating construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below through specific embodiments in conjunction with the accompanying drawings.

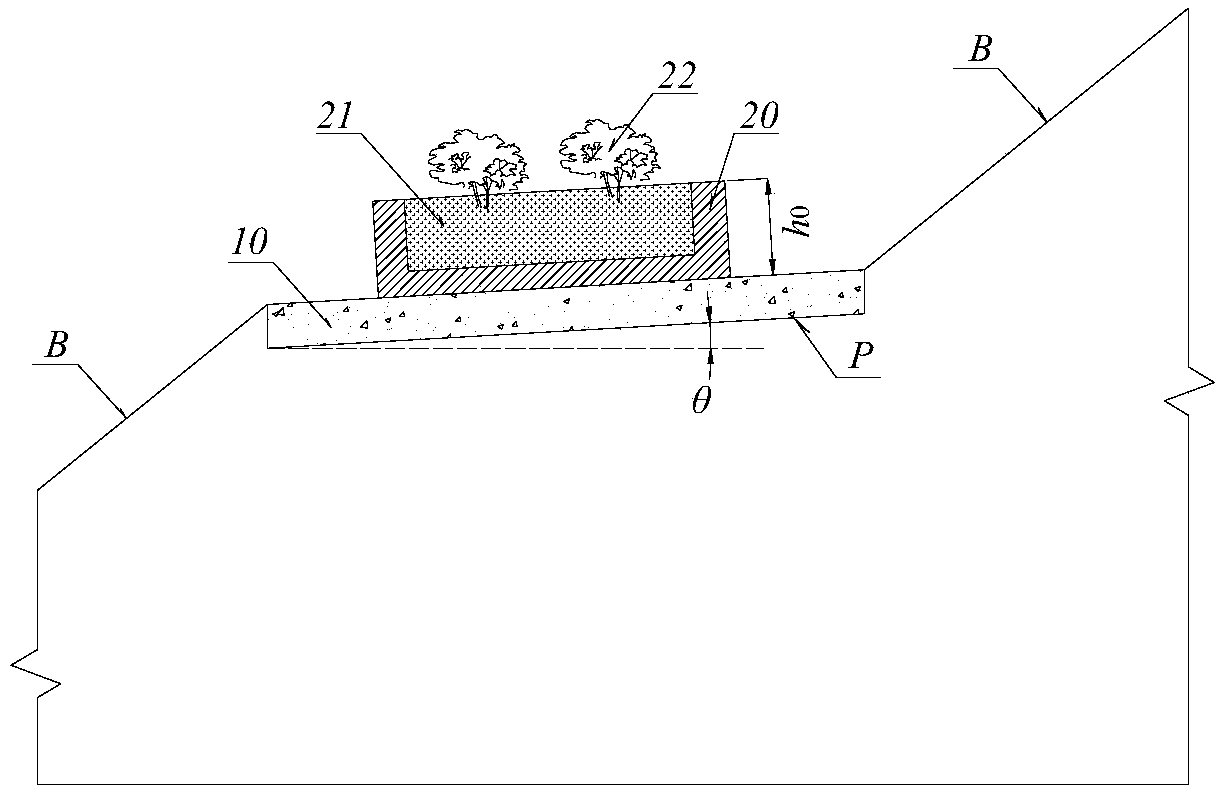

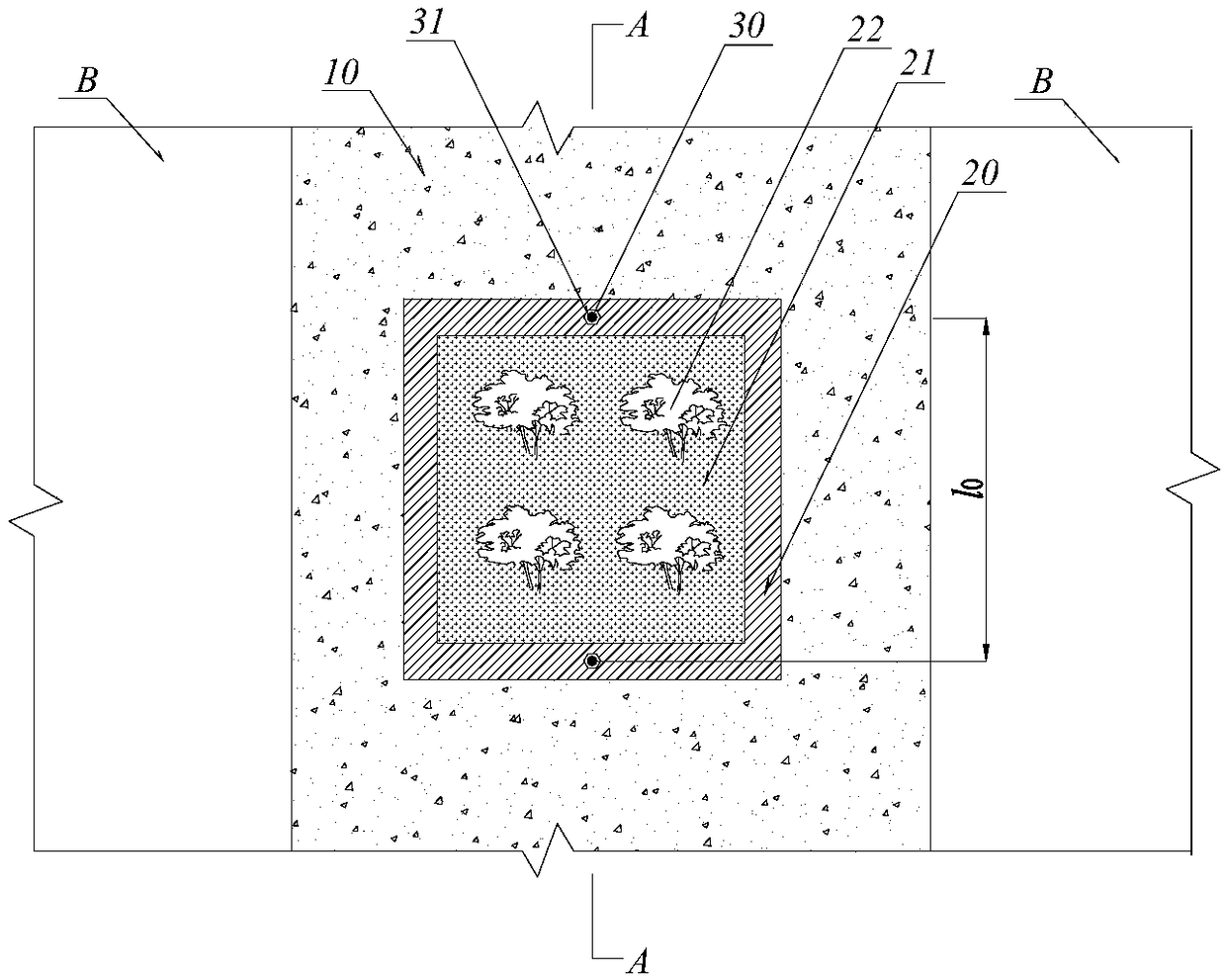

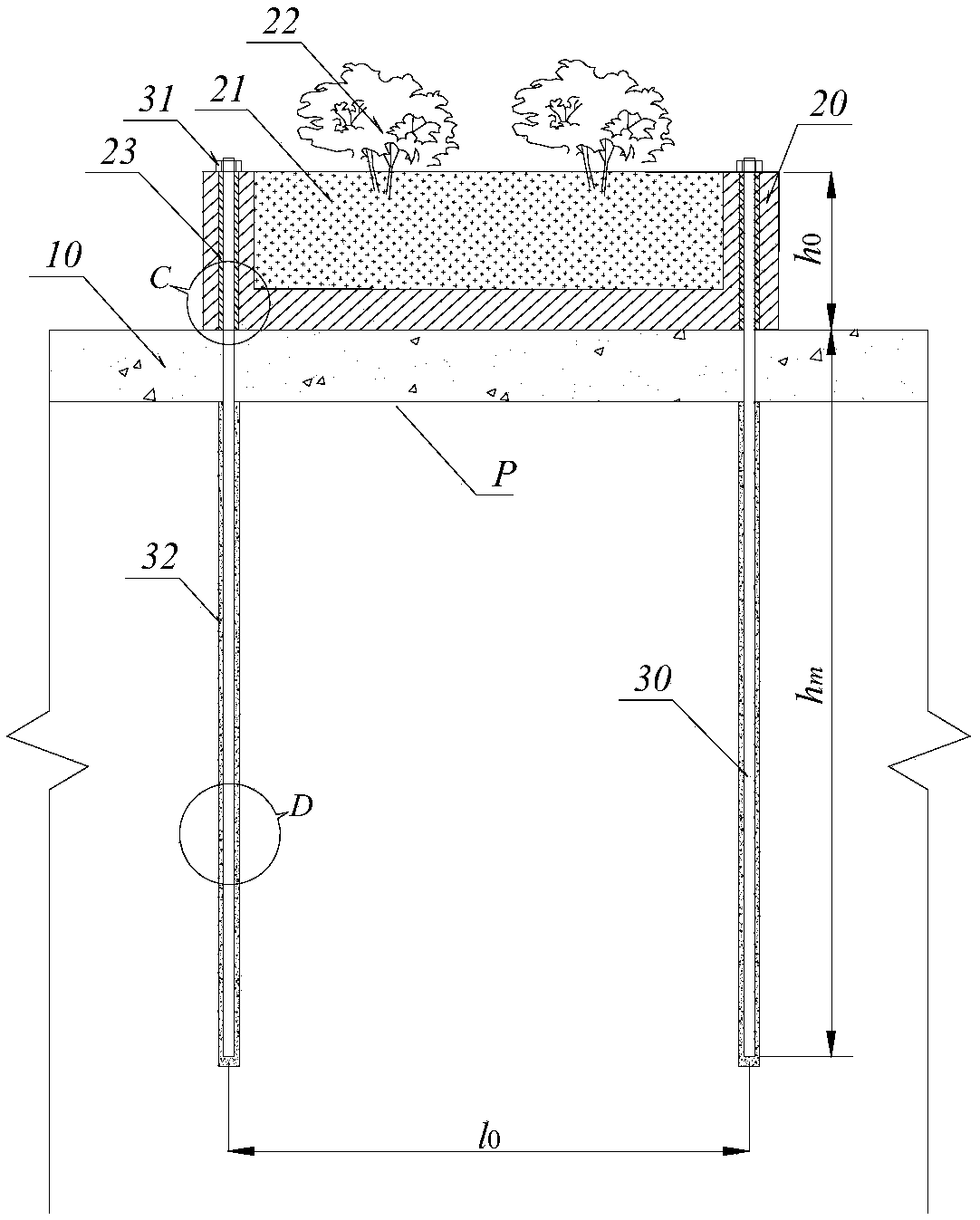

[0022] refer to figure 1 , figure 2 , image 3 , the present invention is a kind of roadbed slope platform planting reinforcement type green groove structure, including slope platform P and the platform sealing layer 10 that seals it. On the platform sealing layer 10, prefabricated greening grooves 20 are arranged at intervals along the transverse direction, and anchor members are arranged on the lateral side walls of the prefabricated greening grooves 20. In and anchored to the underlying foundation. The prefabricated greening groove 20 is filled with planting soil 21 for planting greening plants 22 . The slope platform P is arranged between two adjacent subgrade slopes B, and between the subgrade slope B and a drainage ditch or a side ditch.

[0023] refer to figure 1 , the prefabricated greening tank 20 is a reinforced concrete st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com