Coating painting roller for constructional engineering

A construction engineering and coating technology, which is applied in the direction of architecture and building construction, can solve the problems of reducing the quality of painting and uneven distribution of coatings, and achieve the effects of improving efficiency and quality, avoiding clogging, and reducing volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

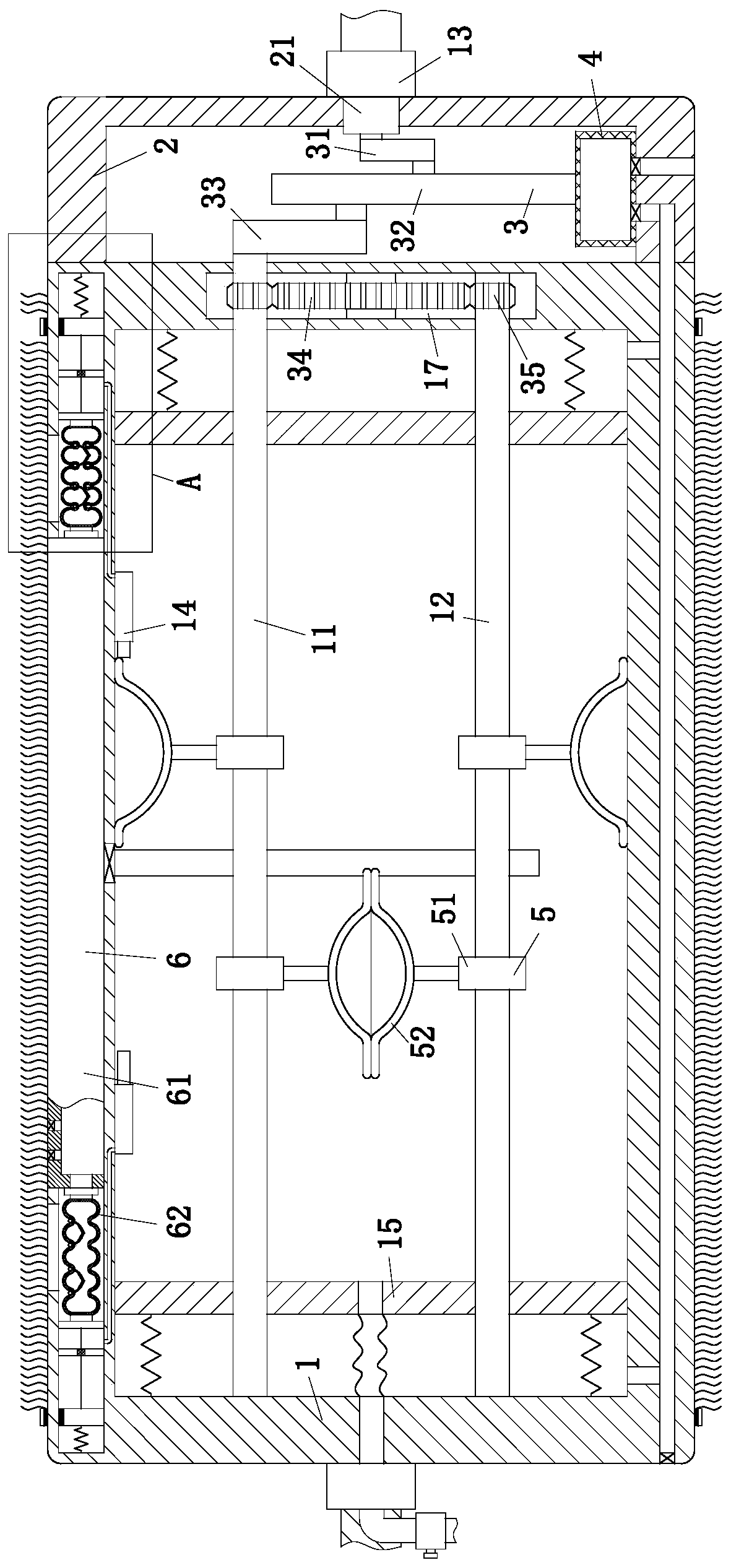

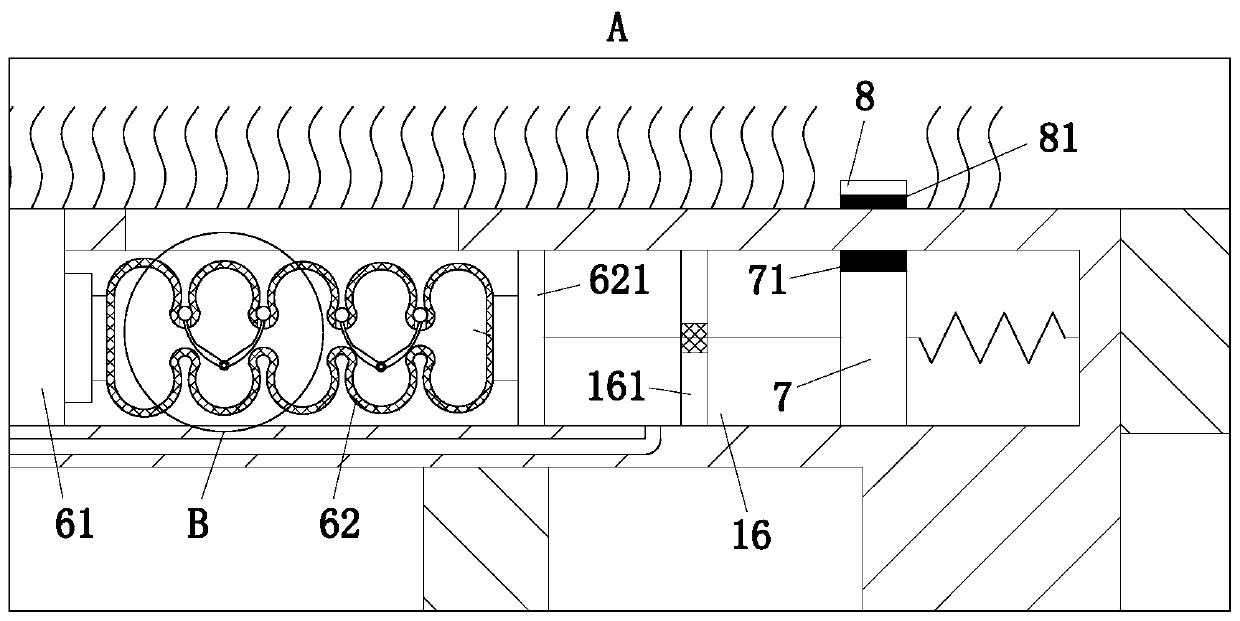

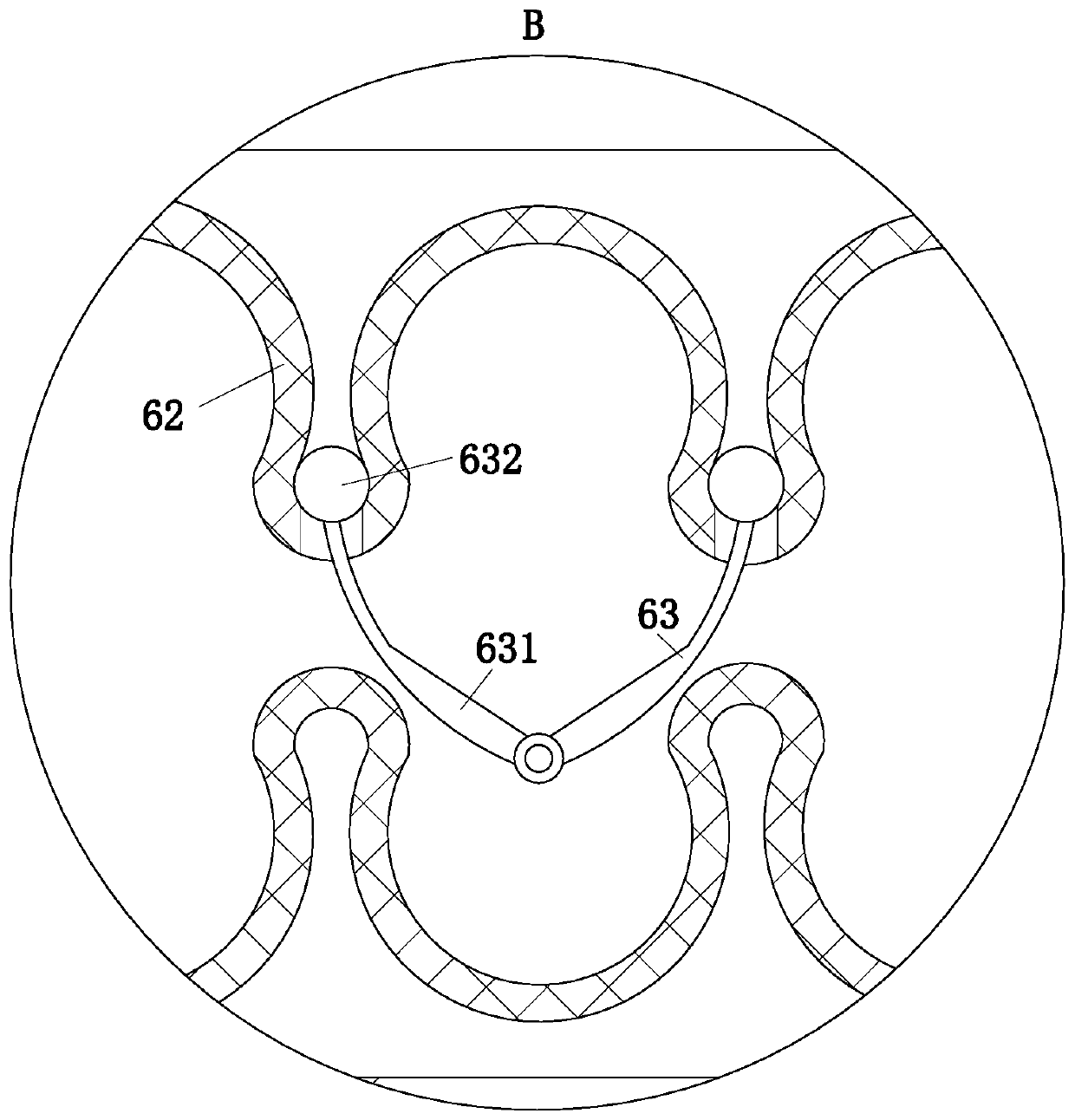

[0028] Such as Figure 1 to Figure 3 As shown, a paint painting roller for construction engineering includes a roller body 1, a rotating connection part 13, a drive module 3, an annular sleeve 2, a motor 21, a stirring module 5 and a liquid drainage module 6; the outer side of the roller body 1 The sleeve is provided with a soft wool sleeve, and one end of the roller body 1 is fixedly connected to the annular sleeve 2, and the end of the annular sleeve 2 and the roller body 1 is equipped with a rotating connection part 13, and one end of the roller body 1 is located on the annular sleeve. The drive module 3 is installed on the inner side of the roller body 1, the first rotating connecting rod 11 and the second rotating connecting rod 12 are instal...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap