One-hole multi-line sealing device and method for high-temperature probe in thickened oil thermal recovery experiment

A heavy oil thermal recovery, medium and high temperature technology, applied in the directions of engine sealing, fluid extraction, earthwork drilling, etc. Reliable and versatile results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to further understand the content, features and effects of the present invention, the following examples are given, and detailed descriptions are given below with reference to the accompanying drawings.

[0029] The invention provides a brand-new all-metal sealing structure with a temperature resistance of 1000°C, which can meet the pressure and temperature indicators of deeper formations, meet broader experimental research, provide support for deep geological strata research, and broaden the scope of related research. The scope of application of the instrument and equipment.

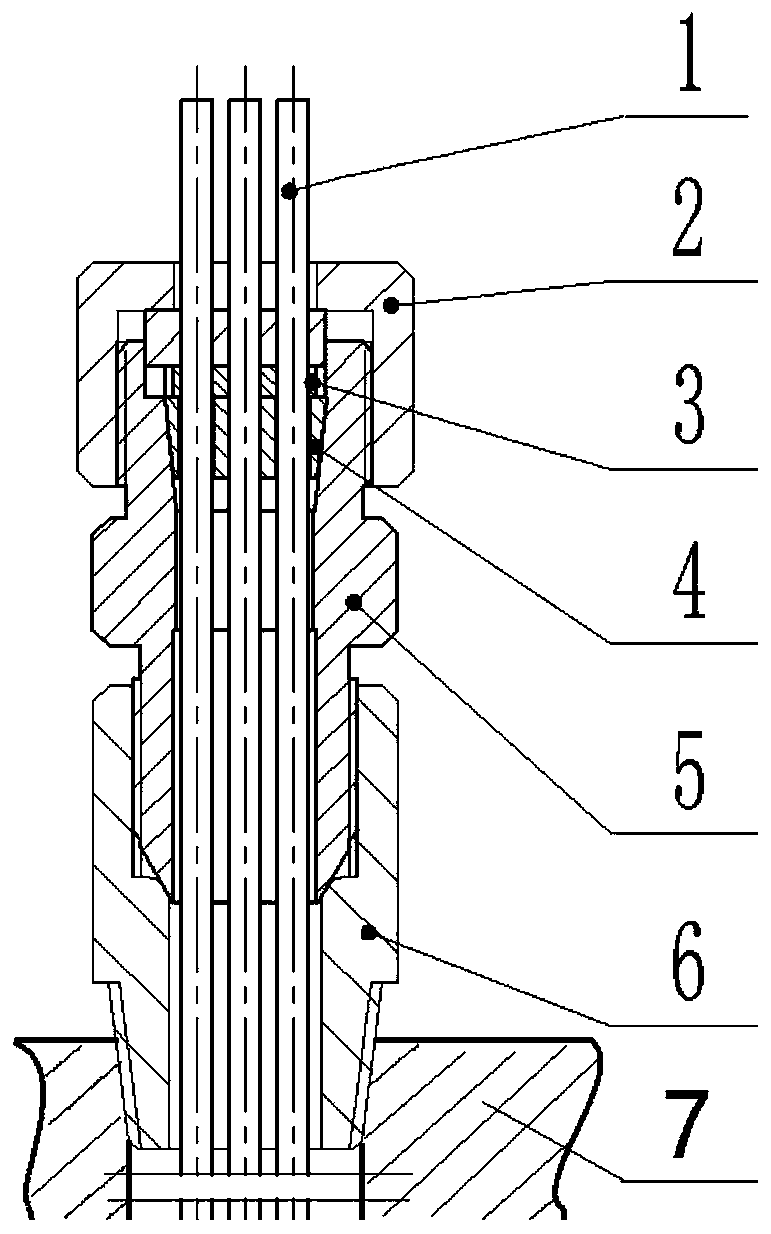

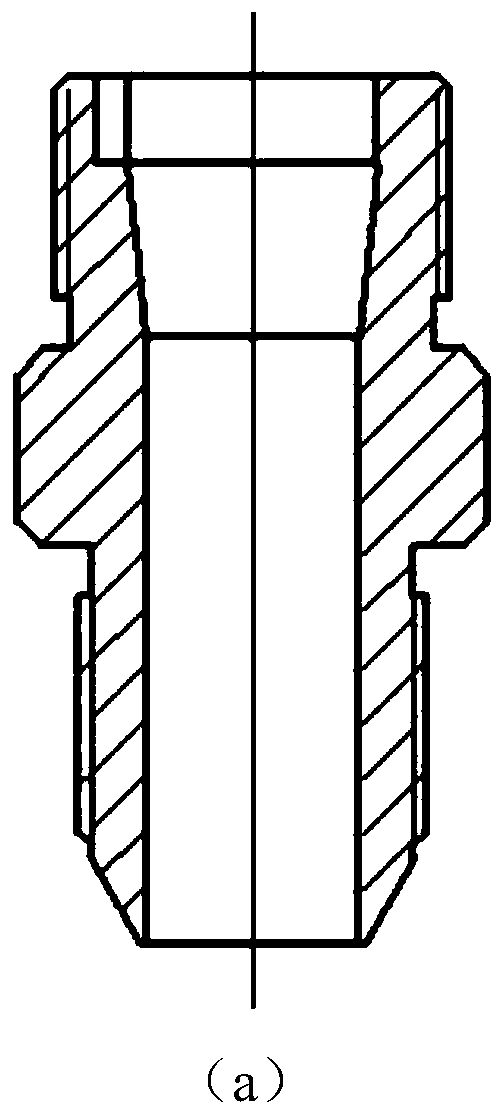

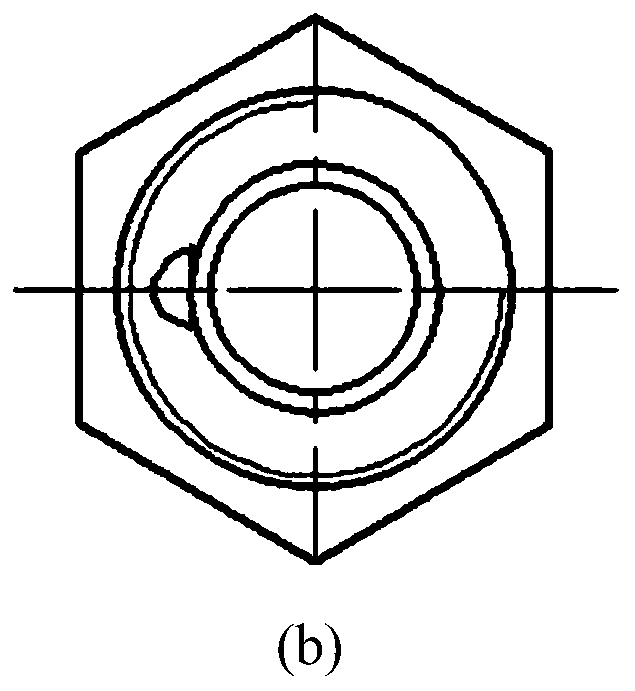

[0030] Attached below Figure 1 to Figure 4 The structure of the present invention is described in detail.

[0031] like Figure 1-Figure 4 As shown, the one-hole multi-line sealing device used for the high temperature probe in the heavy oil thermal recovery experiment provided by the embodiment of the present invention is provided with: a plurality of temperature measuring columns 1; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com