Low-pressure cylinder optimization system for ultra-low load operation of coal-fired unit

A technology for coal-fired units and load operation, applied to mechanical equipment, steam engine devices, engine components, etc., can solve problems such as low-pressure cylinder blowing loss, increase steam intake, ensure safety and reliability, and improve economic efficiency sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

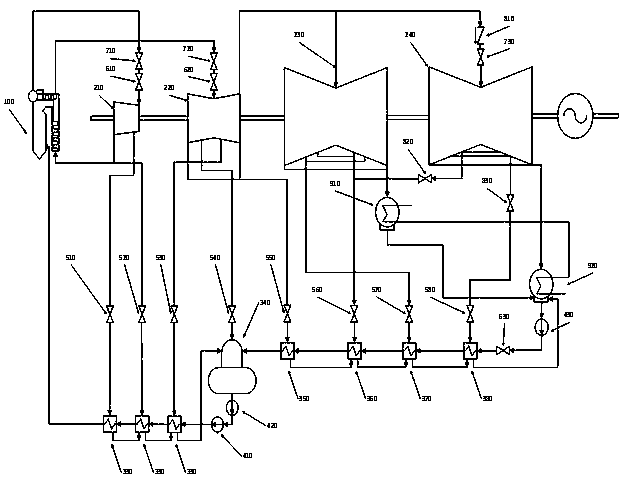

[0034] When the unit is running normally with full load, the steam-water circulation process is as follows: figure 1 As shown, the exhaust steam from the medium pressure cylinder 220 enters the first low pressure cylinder 230 and the second low pressure cylinder 240 to perform work. At this time, the first isolation valve 730 , the second isolation valve 820 and the third isolation valve 830 of the isolation valves are all in a fully open state without any throttling effect.

example 2

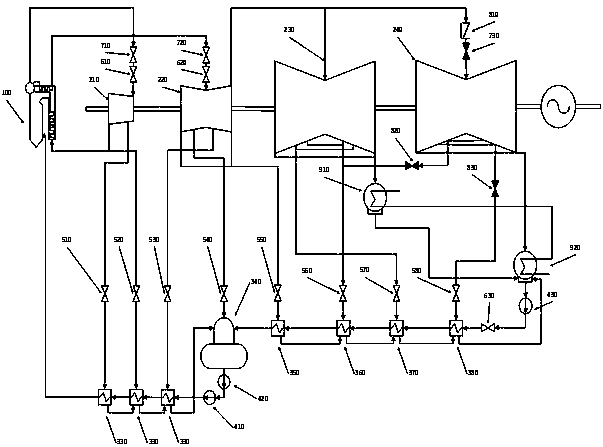

[0036] When the unit drops from full load to below 50% load, the steam-water circulation process is as follows: figure 2 shown. At this time, the first isolation valve 730 in the steam inlet pipeline of the first low-pressure cylinder 230 is fully closed, the second isolation valve 820 and the third isolation valve 830 in the steam extraction pipeline are both fully closed, and the steam-water circulation of the unit is not closed. Passing through the second low-pressure cylinder 240, the second low-pressure cylinder 240 is isolated, the exhaust steam of the medium-pressure cylinder 220 is merged into the first low-pressure cylinder 230 to expand and work, and the low-pressure cylinder part of the unit adopts single-cylinder operation. When isolating the second low-pressure cylinder 240, the specific operation process for the unit to be put into operation with a single low-pressure cylinder is as follows:

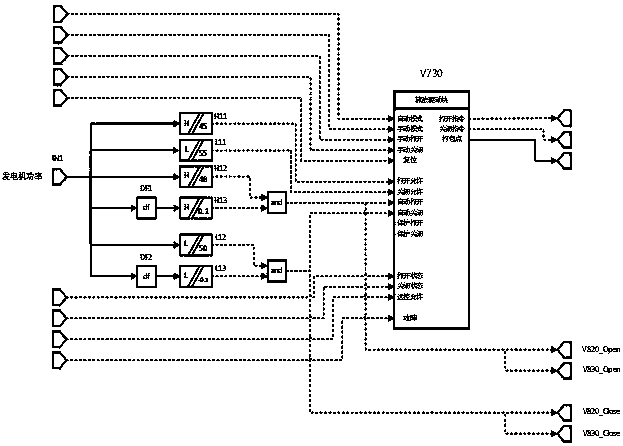

[0037] 1. When the unit load drops below 55%, image 3 Medium low v...

example 3

[0042] When the unit load rises from low load to over 50% load, the steam-water circulation process is changed from figure 2 The process is reconverted to figure 1 shown. At this time, the first isolation valve 730 in the steam intake pipeline of the first low-pressure cylinder 230 is fully open, the isolation valves 820 and 830 in the steam extraction pipeline are both in a fully open state, and the exhaust steam of the medium-pressure cylinder enters the low-pressure cylinder 230 and the low-pressure cylinder 230. Expansion works in the low-pressure cylinder 240, and the low-pressure cylinder part of the unit adopts double low-pressure cylinders to operate. The specific operation process of putting the unit into double low-pressure cylinder operation is as follows:

[0043] 1. When the load of the unit rises to more than 45%, image 3 Among the high value alarm H11, Figure 4 The high value alarm H21 and Figure 5 The high-value alarm H31 in the middle triggers an alar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com