Stirling refrigerator regenerator shell structure and bonding method for abrasion-proof layer thereof

A technology of shell structure and bonding method, which is applied in the bonding method of surface pretreatment, refrigerator, refrigeration and liquefaction, etc., can solve the problems of powder falling off, falling off of spray coating, and weak bonding on the surface of regenerator shell, etc. , to achieve the effect of avoiding powder drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with accompanying drawing:

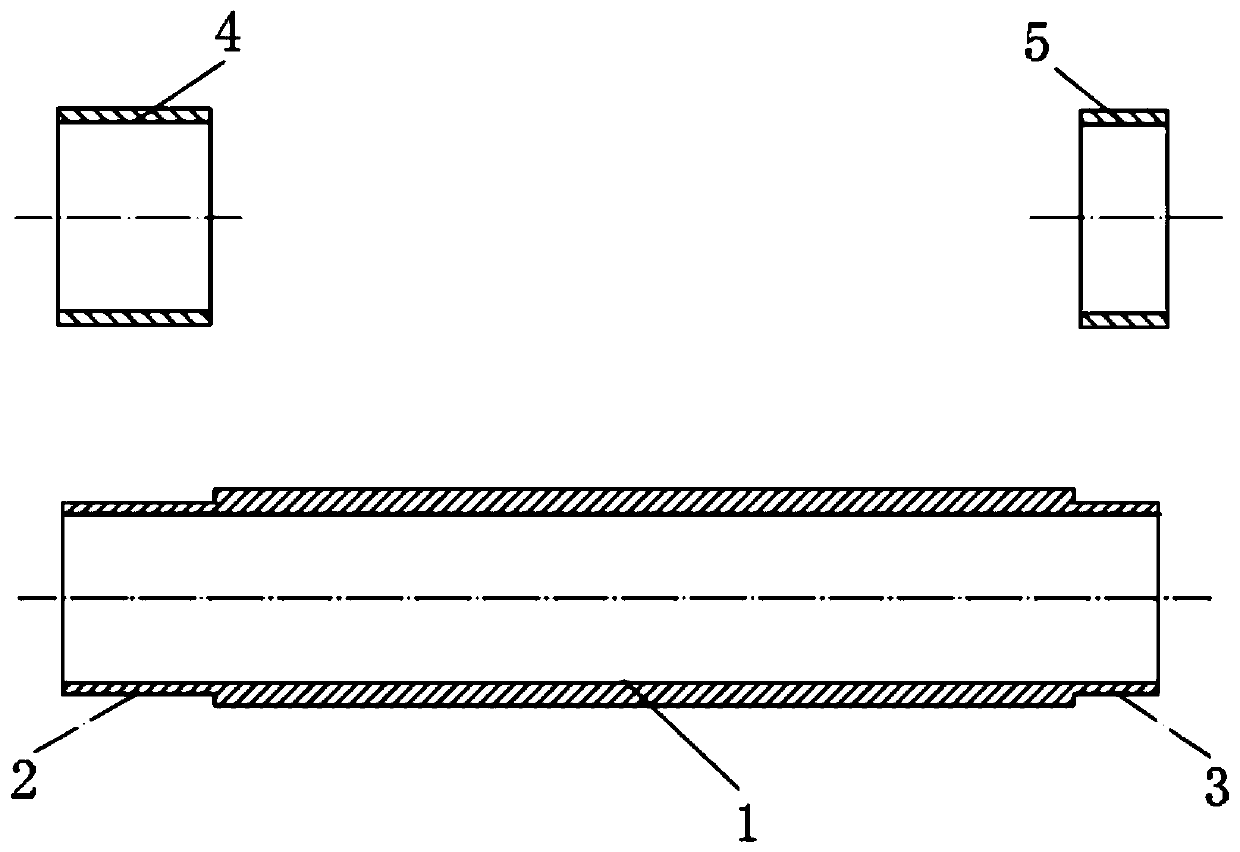

[0025] Such as figure 1 The shown structure of a regenerator shell of a Stirling refrigerator includes a regenerator shell; The hot end 2 of the regenerator shell and the cold end 3 of the regenerator shell at the left and right ends; The outer side of the end 3 is covered with a cold-end wear-resistant layer 5; the hot-end wear-resistant layer 4 and the cold-end wear-resistant layer 5 are both molded by polyimide-based materials.

[0026] Further, the main body 1 of the regenerator shell, the hot end 2 of the regenerator shell and the cold end 3 of the regenerator shell are all ring-shaped, and the inner diameters of the three are equal. The outer diameters of the cold end 3 of the regenerator shell are smaller than the outer diameter of the main body 1 of the regenerator shell.

[0027] Further, the wear-resistant layer 4 at the hot end and the wear-resistant layer 5 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com