Integrated scheduling method for multi-roadway automatic stereoscopic warehouse based on mixed integer programming model

A mixed integer programming and three-dimensional warehouse technology, applied in data processing applications, character and pattern recognition, instruments, etc., can solve problems such as poor control effect, slow integrated scheduling method, and low solution efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

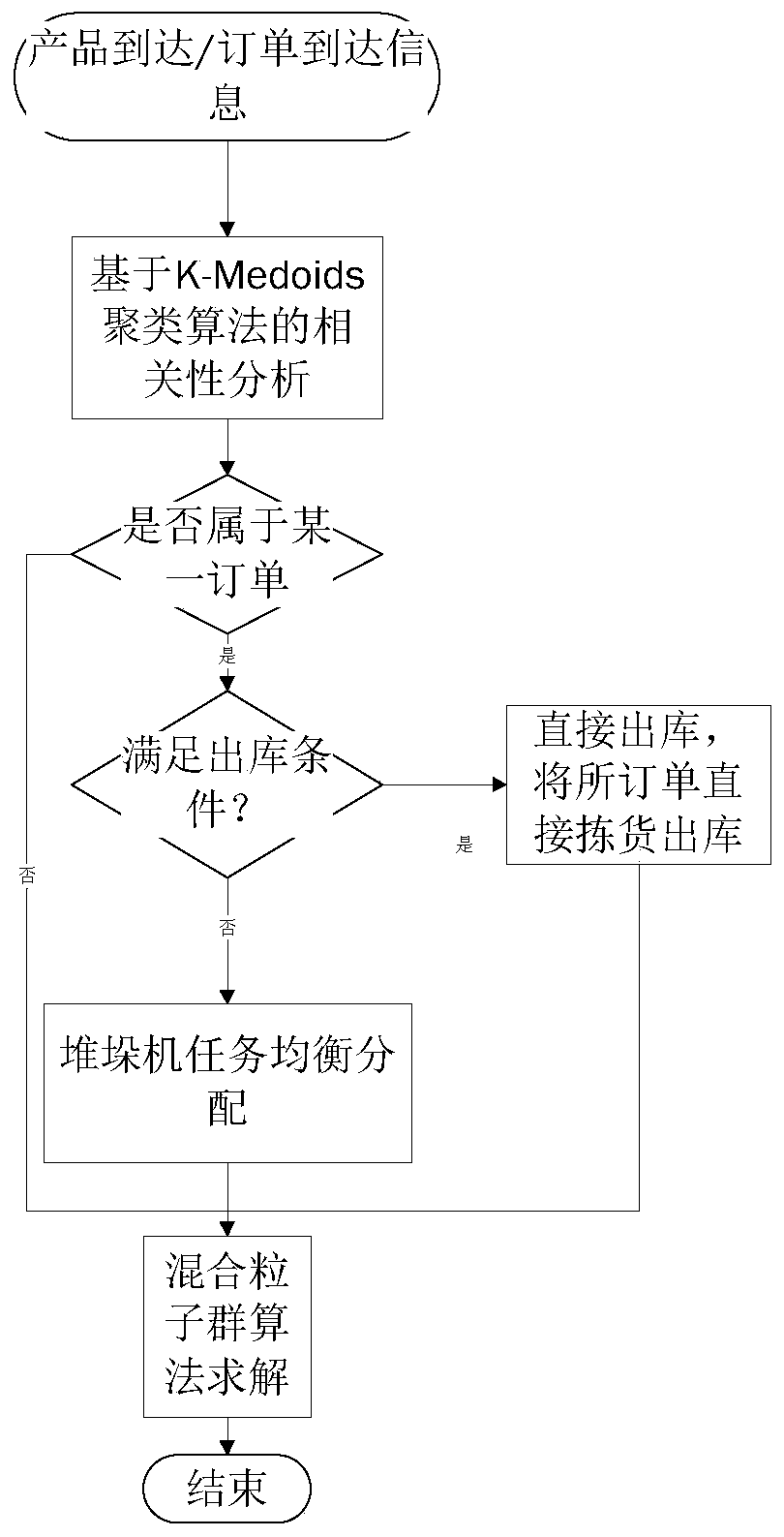

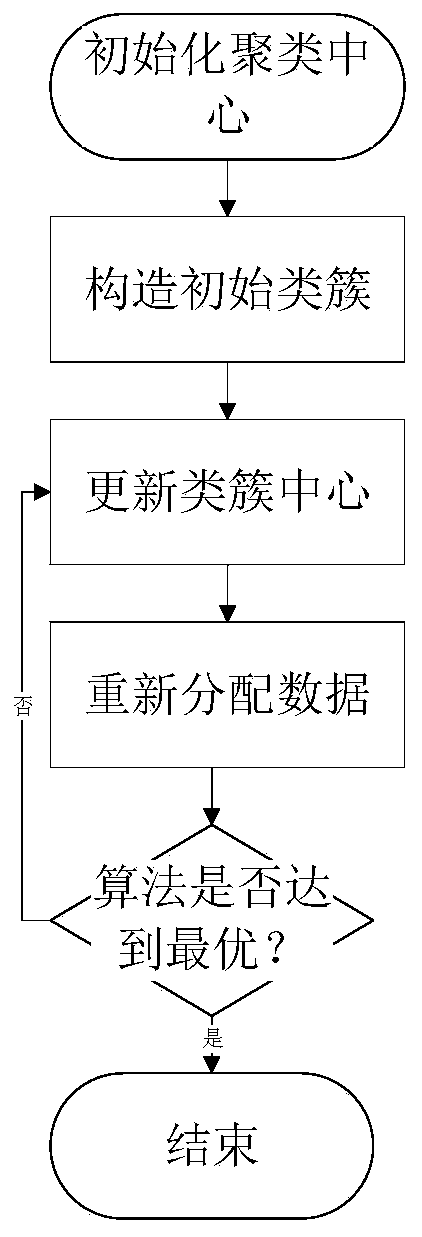

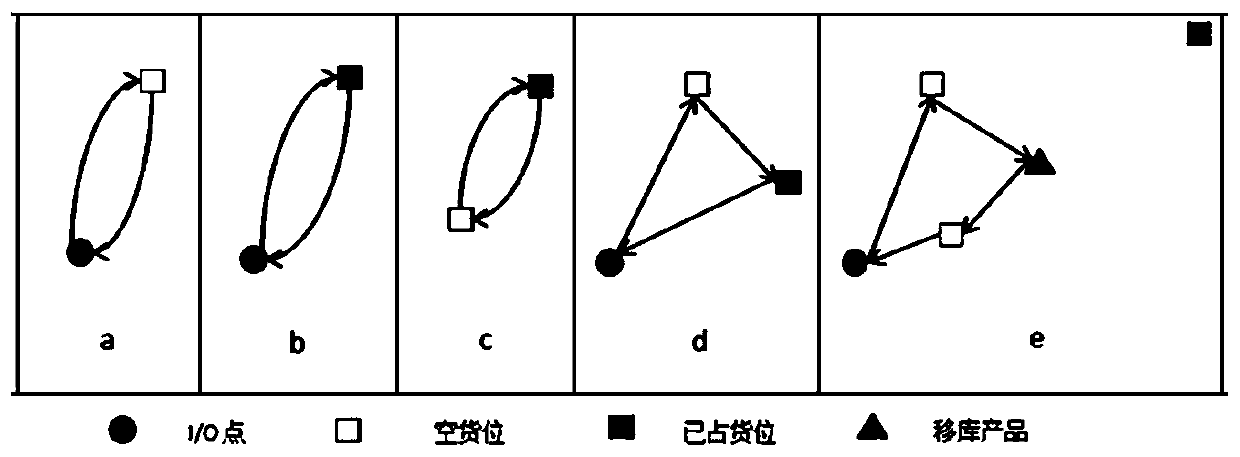

Method used

Image

Examples

example

[0164] Example: Consider a three-dimensional warehouse with six shelves, with 15 floors and 100 rows of shelves, 3*2*15*100=9000 storage spaces, each storage space is 2.98m*1.12m in size, and the stacker is in the horizontal and vertical directions The maximum speed on the road is 2.1m / s and 0.75m / s respectively, and the acceleration is 0.4m / s respectively 2 and 0.6m / s 2 . The maximum transport capacity of the stacker is one pallet, and the number of storage / retrieval operations of the stacker is randomly generated every day. There are 300 products in total, and the quantity of each product in the warehouse is a random integer of 10-15; the order is 100, and each order contains a random integer of 1-5 product types, and the quantity of each product is 5-10 Random integers; 100 times of products entering the warehouse, each containing a random integer with a product type quantity of 1-5, and a random integer with a quantity of each product of 5-10.

[0165] Table 3 Average P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com