An ultrasonic-assisted pillar planting method for cucga device packaging

An ultrasonic-assisted and device packaging technology, which is applied to the assembly of printed circuits with electrical components, electrical solid devices, semiconductor devices, etc., can solve the problem of solder joint porosity and solder post scratch damage, large impact on the quality of planted posts, and welding heat transfer. Bad and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

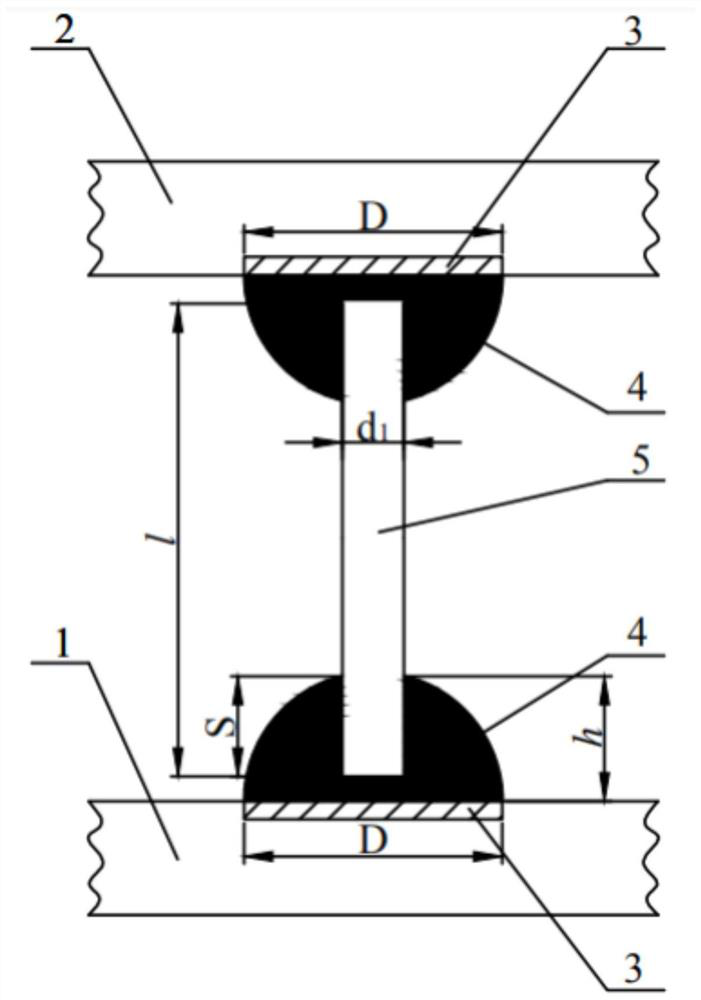

[0044]An ultrasonic assisted pillar planting method for CuCGA device packaging includes the following steps:

[0045]Step 1. Print solder paste with non-eutectic point solder composition on the pads arranged in the array:

[0046]Same as the traditional BGA ball planting process, a sufficient amount of non-eutectic point solder composition solder paste is printed on the pads arranged in the array of the printed circuit board and the chip carrier substrate by means of a mature stencil printing process;

[0047]Step 2. Realize the ball planting on the pads arranged in the array on the printed circuit board and the chip carrier substrate by reflow soldering:

[0048]The solder paste on the pads arranged in an array on the printed circuit board and the chip carrier substrate is heated to melt, the flux in the solder paste removes the oxide film on the pads, and the solder in the solder paste wets the pads, and The solder balls arranged in an array are formed under the action of surface tension;

[004...

specific Embodiment approach 2

[0059]The material of the pads arranged in the array in this embodiment is any one of copper, gold, silver, nickel, tin bronze, brass, or a combination of copper, gold, silver, nickel, tin bronze, or brass The multilayer metal film pad formed by the combination may also be one of the metals or alloys on which other tin-based solders can be well wetted.

[0060]The other steps and parameters are the same as in the first embodiment.

specific Embodiment approach 3

[0062]The diameter of the pads arranged in the array according to this embodiment is D, 0.9mm≦D≦3mm, and the thickness of the pads arranged in the array is 35 μm-100 μm.

[0063]The other steps and parameters are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com