Tufted carpet

A technology of tufted carpets and pile yarns, applied in carpets, textiles, papermaking, embroidery machines, etc., can solve the problems of unstable pile structure, easy to fall off piles, cumbersome production procedures, etc., and achieve stable pile structure and not easy to fall off , The effect of simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

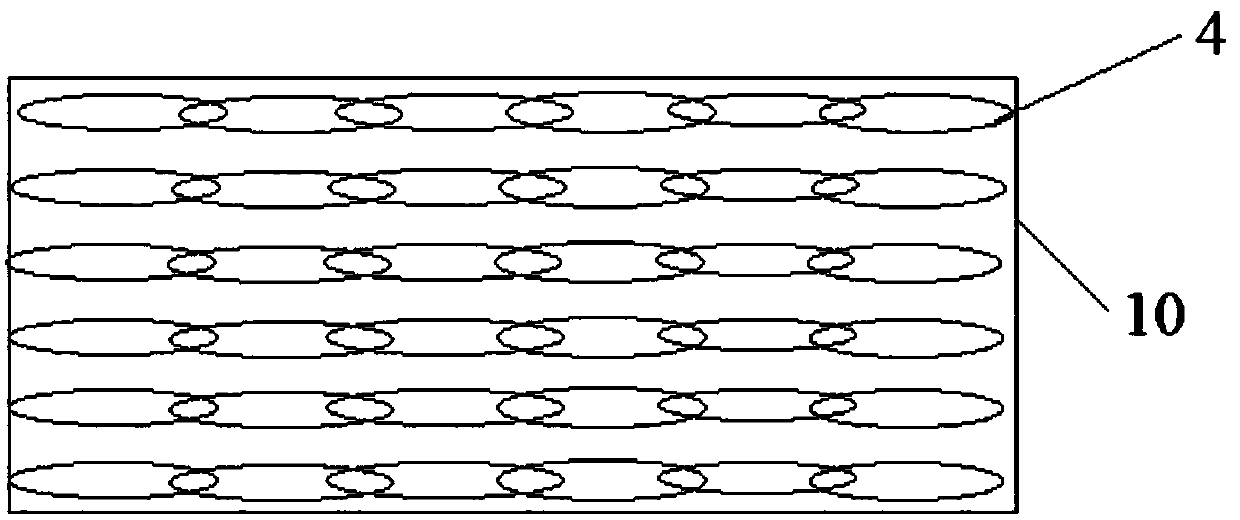

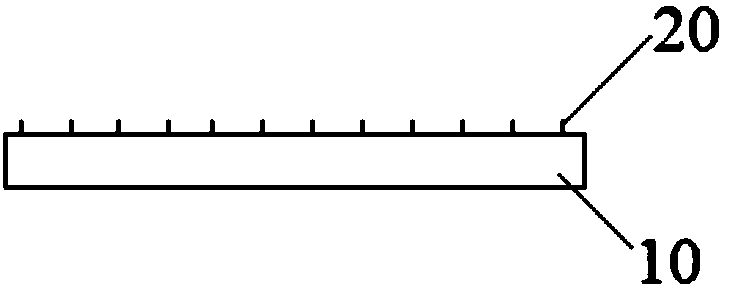

[0019] combine figure 1 with figure 2 As shown, the tufted carpet of the technical solution of the present invention includes a base fabric 10 and a suede surface, the suede surface is located on the base fabric 10 , and the suede surface is formed by pile yarns 20 and has a chain structure 4 .

[0020] The technical solution of the present invention will be described in detail below in conjunction with the embodiments.

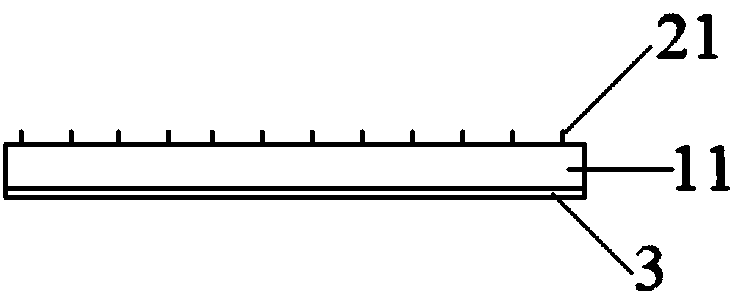

[0021] Such as image 3 As shown, the tufted carpet of the embodiment of the present invention includes a suede surface formed by polyester cloth 11 interwoven with warp and weft and cotton yarn 21 .

[0022] In other embodiments, the base fabric 10 can also be other fabrics, such as polypropylene woven fabrics, and the density of the fabrics depends on actual needs. The suede is positioned on the polyester cloth 11, and the suede is formed by raising polypropylene yarn through tufting equipment, or at least one selected from natural fiber yarn, synthetic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com