Construction method of soft soil roadbed

A construction method and technology of soft soil subgrade, applied to roads, roads, building components, etc., to reduce settlement, improve stability, and achieve good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

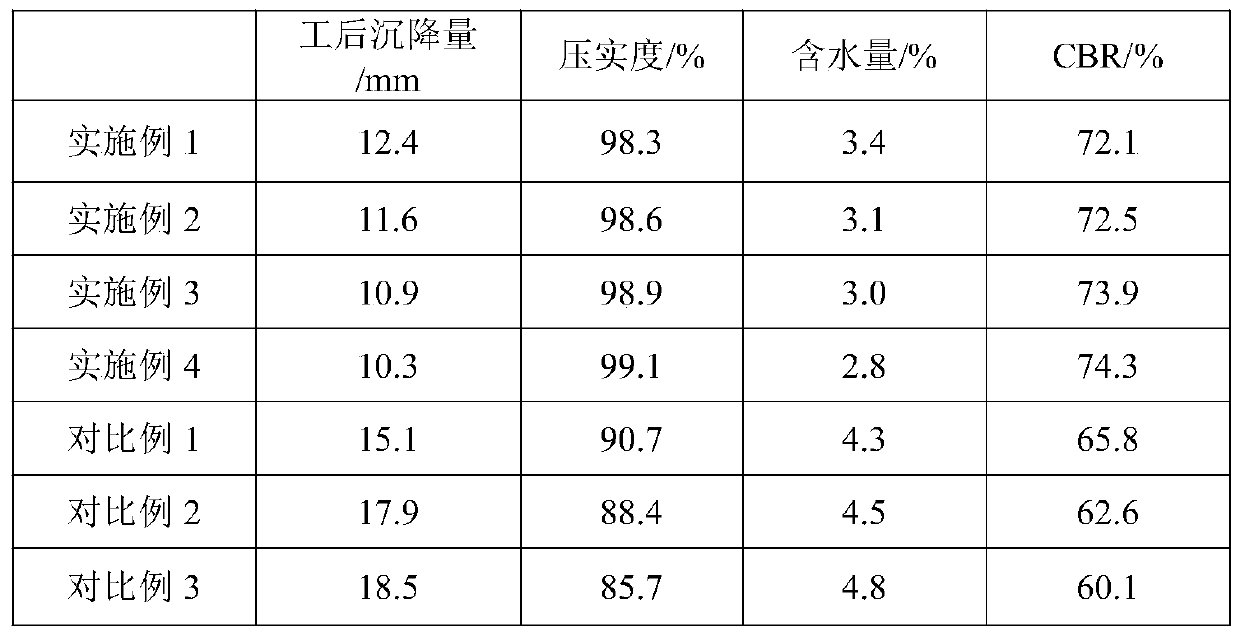

Examples

Embodiment 1

[0044] A construction method for a soft soil subgrade, comprising the steps of:

[0045] (1) Ground garbage cleaning, cleaning thickness 15cm, leveling the ground to form a roadbed;

[0046] (2) Set-out positioning, press-fitting, and pile fixing of prestressed pipe piles;

[0047] (3) Excavate the roadbed to the target depth of 10cm, backfill with fly ash, and roll compactly;

[0048] (4) Pave a mixture of crushed stone and slag, the particle size of the crushed stone is 5mm, the particle size of the slag is 3mm, the mass ratio of the crushed stone and the slag is 3:1, and the paving thickness is 8cm;

[0049] (5) Pouring modified asphalt, pouring in 2 times, each pouring 4cm;

[0050] (6) Roadbed compaction, use a road roller to roll both sides of the roadbed first, then roll the middle of the roadbed, the rolling overlap distance is 35cm, use small gravel to fill the gaps in the roadbed, the degree of compaction and flatness of the roadbed is 85%;

[0051](7) Drainage pr...

Embodiment 2

[0056] A construction method for a soft soil subgrade, comprising the steps of:

[0057] (1) Ground garbage cleaning, cleaning thickness 35cm, leveling the ground, forming a roadbed;

[0058] (2) Set-out positioning, press-fitting, and pile fixing of prestressed pipe piles;

[0059] (3) Excavate the roadbed to the target depth of 15cm, backfill with rocky soil and sandy soil, the mass ratio of rocky soil to sandy soil is 1:2, and roll compactly;

[0060] (4) Pave a mixture of gravel, slag and lime soil, the mass ratio of the three is 2:1:1, the particle size of the gravel is 15mm, the particle size of the slag is 3mm, the particle size of lime soil is 10mm, and the paving thickness is 12cm ;

[0061] (5) Pouring modified asphalt, pouring in 3 times, each pouring 5cm;

[0062] (6) Roadbed compaction, use a road roller to roll both sides of the roadbed first, then roll the middle of the roadbed, the rolling overlap distance is 50cm, use stone chips to fill the gaps in the roa...

Embodiment 3

[0068] A construction method for a soft soil subgrade, comprising the steps of:

[0069] (1) Ground garbage cleaning, cleaning thickness 25cm, leveling the ground, forming roadbed;

[0070] (2) Set-out positioning, press-fitting, and pile fixing of prestressed pipe piles;

[0071] (3) Excavate the roadbed to the target depth of 12cm, backfill with rocky soil and sandy soil, the mass ratio of rocky soil to sandy soil is 2:1, and roll compactly;

[0072] (4) Pave a mixture of gravel, slag and lime soil, the mass ratio of the three is 3:2:1, the particle size of the gravel is 10mm, the particle size of the slag is 6mm, the particle size of lime soil is 8mm, and the paving thickness is 10cm ;

[0073] (5) Pouring modified asphalt, pouring in 3 times, each pouring 4cm;

[0074] (6) Roadbed compaction, use a road roller to roll both sides of the roadbed first, then roll the middle of the roadbed, the rolling overlap distance is 40cm, use stone chips to fill the gaps in the roadbe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com