Civil air defence door leaf with geometric composite structure and manufacturing method

A composite structure, civil air defense door leaf technology, applied in the direction of door leaf, building structure, window/door, etc., can solve the problems of heavy civil air defense door leaf, unfavorable production, transportation and installation, etc., to achieve weight reduction, less consumables, easy transportation and installation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

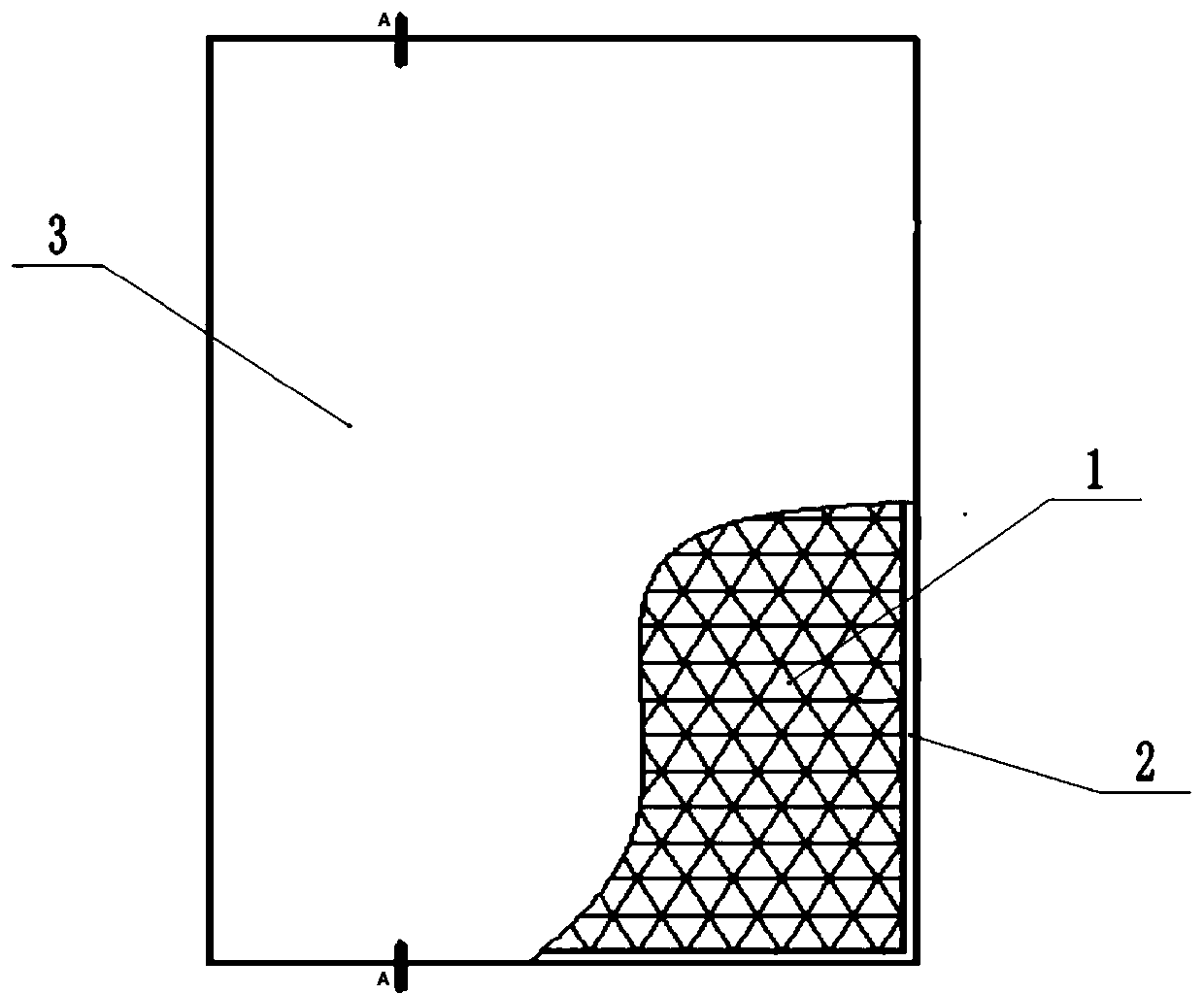

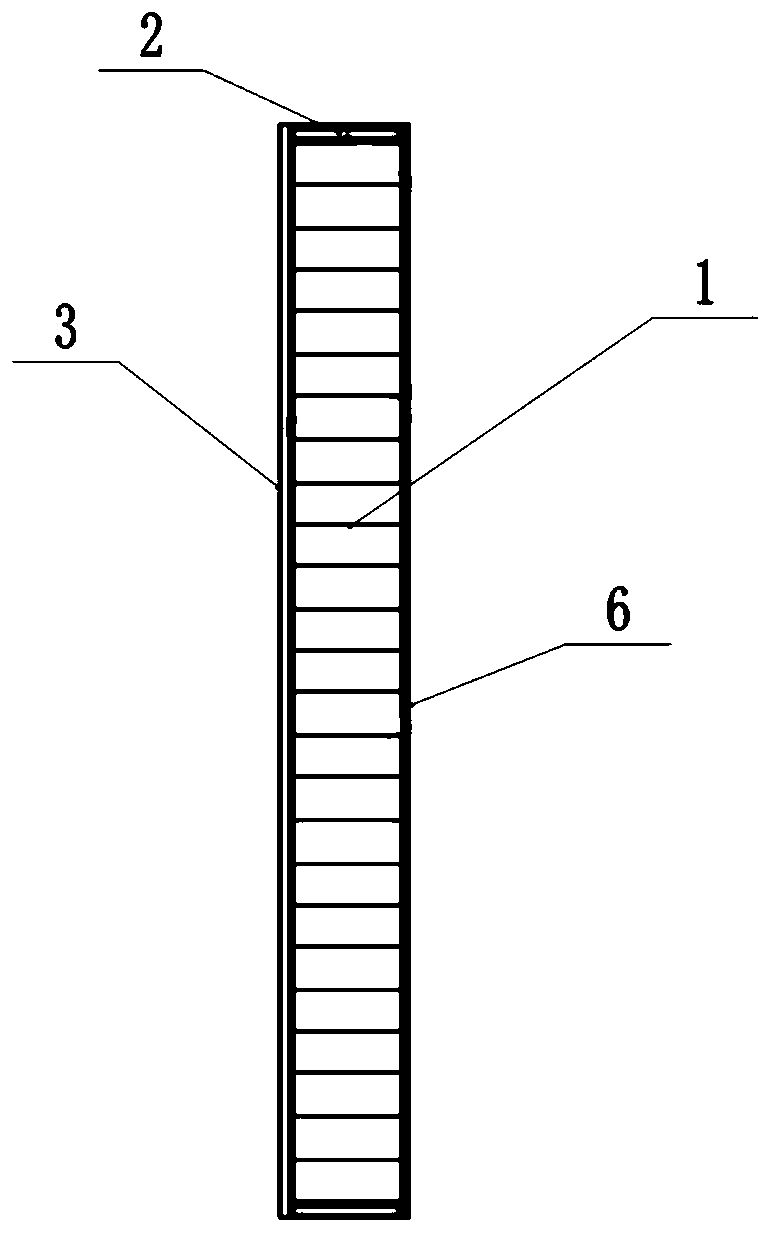

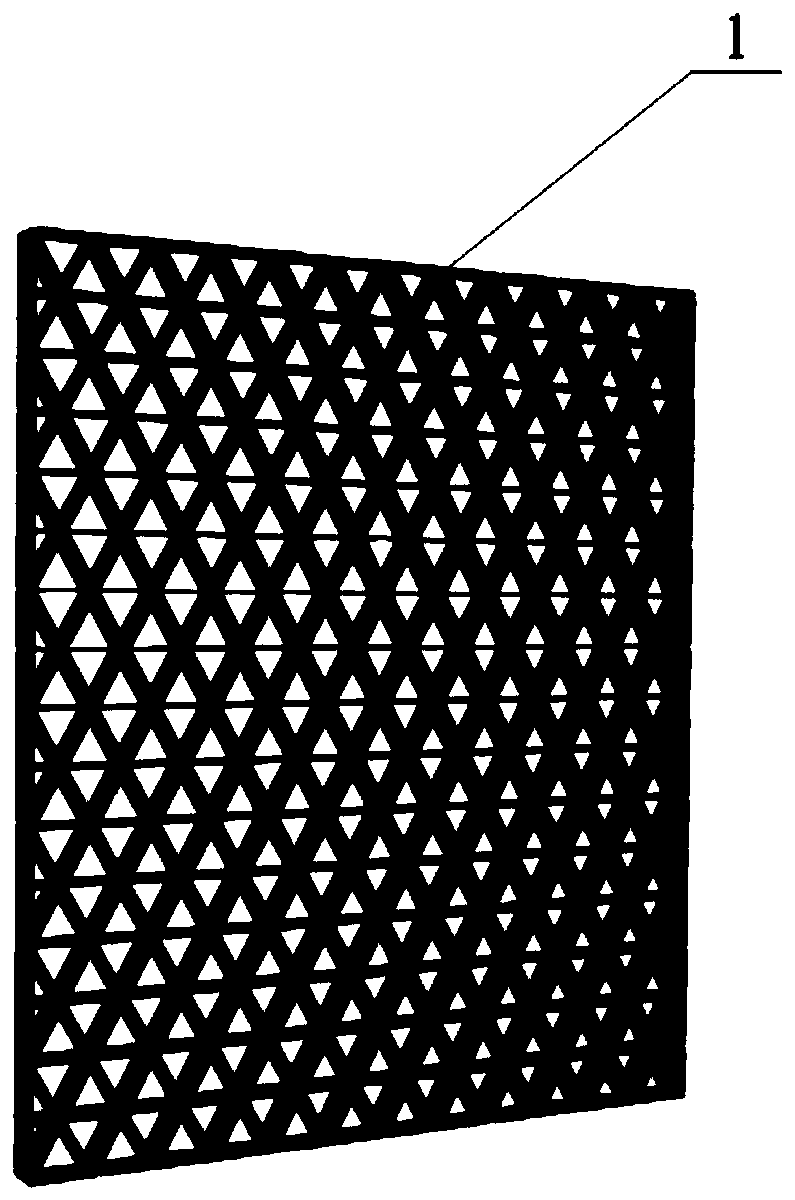

[0049] Basic as attached Figure 1-3 Shown: a civil air defense door leaf with a geometric composite structure, including a door core structure 1, a door leaf frame 2, an upper panel 3 and a lower panel 6, the door core structure 1 is a skeleton structure composed of a continuous geometric structure, and the door leaf outer frame 2. The upper panel 3 and the lower panel 6 are respectively fixed with the door core structure 1 to form a civil air defense door leaf. The geometric structure is a regular triangle, a square, a regular hexagon, a trapezoid, a rhombus, a perfect circle and an ellipse. Such as Figure 4 As shown, the door core structure 1 is welded by several regular triangles. Such as Figure 5 As shown, the door core structure 1 is welded by several squares. Such as Figure 6 As shown, the door core structure 1 is welded by several rhombuses. Such as Figure 7 As shown, the door core structure 1 is welded by several regular hexagons. Such as Figure 9 As sho...

Embodiment 2

[0051] Basic as attached Figure 1-3As shown, a civil air defense door leaf with a geometric composite structure includes a door core structure 1, a door leaf frame 2, an upper panel 3 and a lower panel 6, the door core structure 1 is a skeleton structure composed of a continuous geometric structure, and the door leaf outer frame 2. The upper panel 3 and the lower panel 6 are respectively fixed with the door core structure 1 to form a civil air defense door leaf. The geometric structure is composed of several first profiled parts or a combination of several steel strips 4 and second profiled parts; both the first profiled part and the second profiled part are cold-formed profiles, and the first profiled part It is a continuous zigzag structure 5 or a continuous corrugated structure 7, the second profiled part is a continuous zigzag structure 5; the steel strip 4 is a straight line structure. Several first profiled parts can form a continuous geometric structure with each othe...

Embodiment 3

[0059] A method for manufacturing a civil air defense door leaf of a geometric composite structure, comprising the following steps:

[0060] (1) Manufacture of geometric pipes: prepare round pipes, which are made into geometric pipes by cold drawing, such as regular triangles, squares, trapezoids, rhombuses, regular hexagons, perfect circles or ovals;

[0061] (2) Manufacture the geometric structure: cutting the geometric pipe to form a cylindrical geometric structure;

[0062] (3) Manufacture door core structure 1: Weld several geometric structures into sheet-shaped door core structure 1 (such as Figure 4 , 5 , 6, 7, 9, 10);

[0063] (4) Manufacture the civil air defense door frame: prepare the door leaf frame 2, and weld the prefabricated sheet-like door core structure 1 in the door leaf frame 2 to form the civil air defense door frame (such as image 3 );

[0064] (5) Manufacture the preliminary civil air defense door: prepare the upper panel 3 and the lower panel 6, p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com