Experimental device and experimental method used for studying rock stress distribution by using magnetic fluid

A technology of rock stress and experimental device, used in measurement devices, hydraulic/pneumatic measurement, analysis of materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

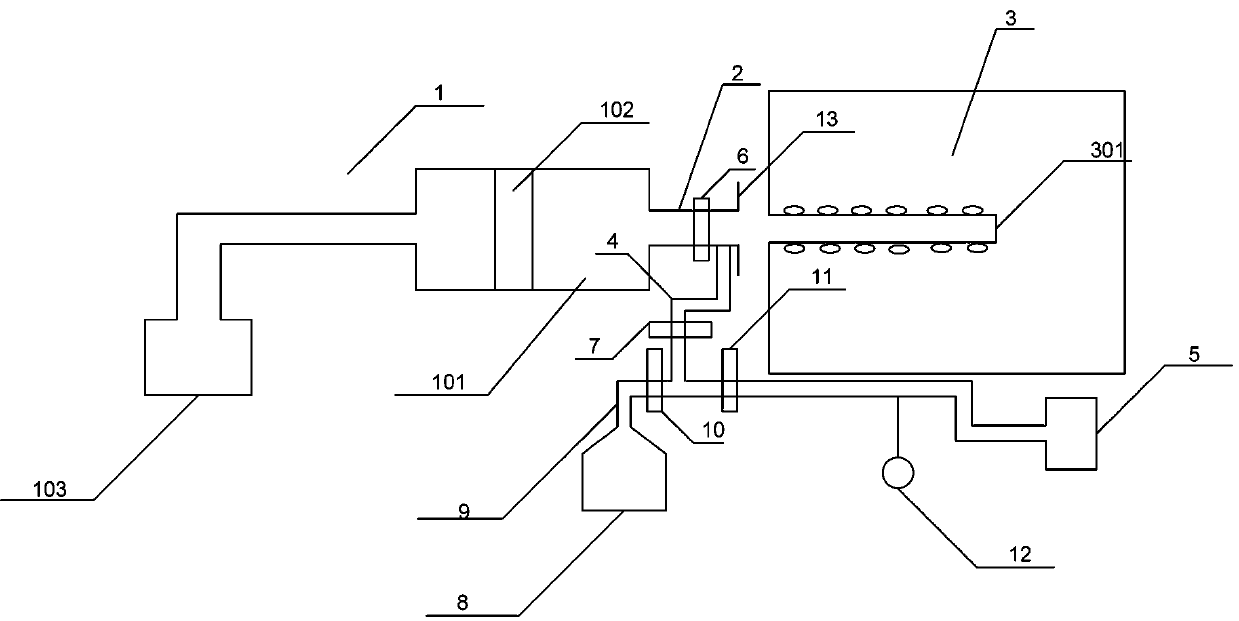

[0028] Embodiment 1: as figure 1 Among them, an experimental device for using magnetic fluid to study rock stress distribution, including a pressing device 1, the outlet of the pressing device 1 is connected to the injection pipe 2, the injection pipe 2 is inserted into the borehole 301 of the sample 3, and the injection pipe 2 is connected to the vacuum pump 5 through the suction pipe 4, the injection pipe 2 is provided with a first valve 6, and the suction pipe 4 is provided with a second valve 7.

[0029] Specifically, the pressing device 1 includes an injection cavity 101 , and a piston 102 is arranged in the injection cavity 101 , and the end of the injection cavity 101 away from the injection tube 2 is connected to a pressure pump 103 through a pipeline.

[0030] The pressure pump 103 can be a hand-held or desktop pressure pump. In this embodiment, a desktop pressure pump is preferred, which can ensure the constant pressure of the pushing material.

[0031] The pipeline...

Embodiment 2

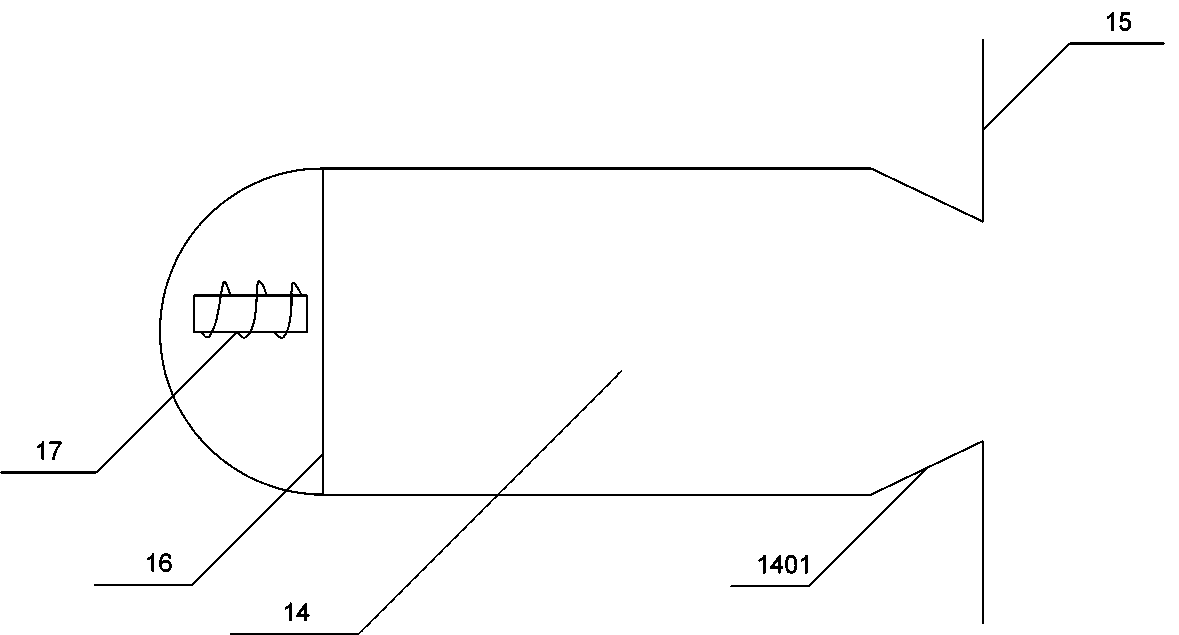

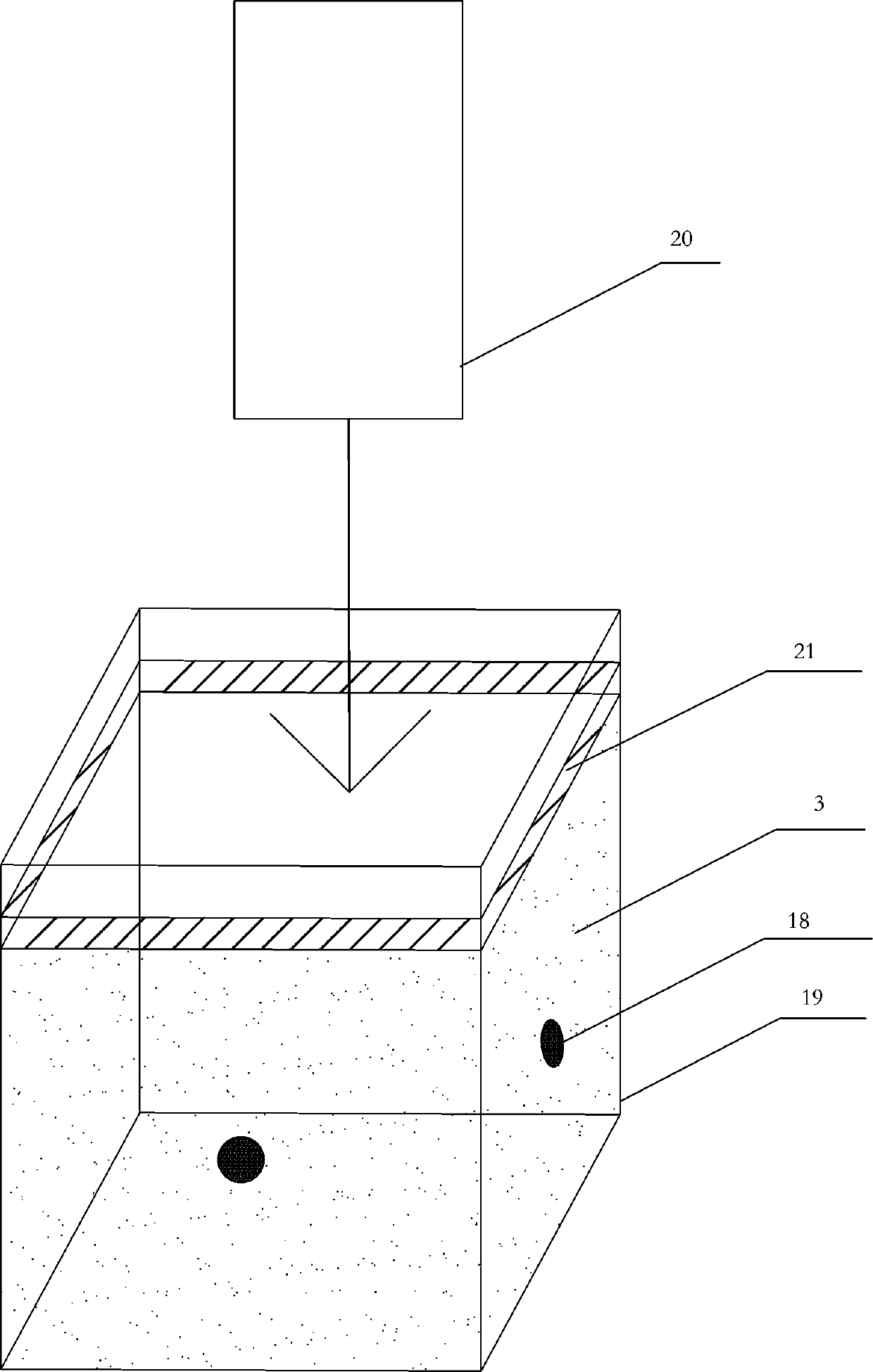

[0058] Embodiment 2: Different from Embodiment 1, in step five, metal powder or magnetic powder is added in the borehole 301. Since the magnetic fluid in the rock pores has magnetism, the metal powder will accumulate on the surface of the hole wall of the rock borehole. Then use a micro-camera to take 3D pictures of the internal images of the borehole to establish a three-dimensional model of the borehole accumulation. The amount of metal powder accumulated on the surface of the wall of the rock borehole reflects the amount of magnetic fluid pressed into the rock pores, and then can be used for analysis. The stress distribution of the rock stress is observed in a straight pipe.

[0059] In step 6, after the measurement is completed, the recovery port 1401 of the recovery chamber 14 of the recovery device is attached to the outside of the borehole 301, and the electromagnet 17 is powered on to recover the magnetic fluid and metal powder in the borehole 301.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com