Preparation method of krill-flavor plant blend oil rich in phospholipid

A technology for blending oil and krill, applied in food science, edible oil/fat, applications, etc., can solve the problems of harmful solvent residues, long time consumption, etc., and achieve the effect of increasing phospholipid content, high conversion efficiency, and broad market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

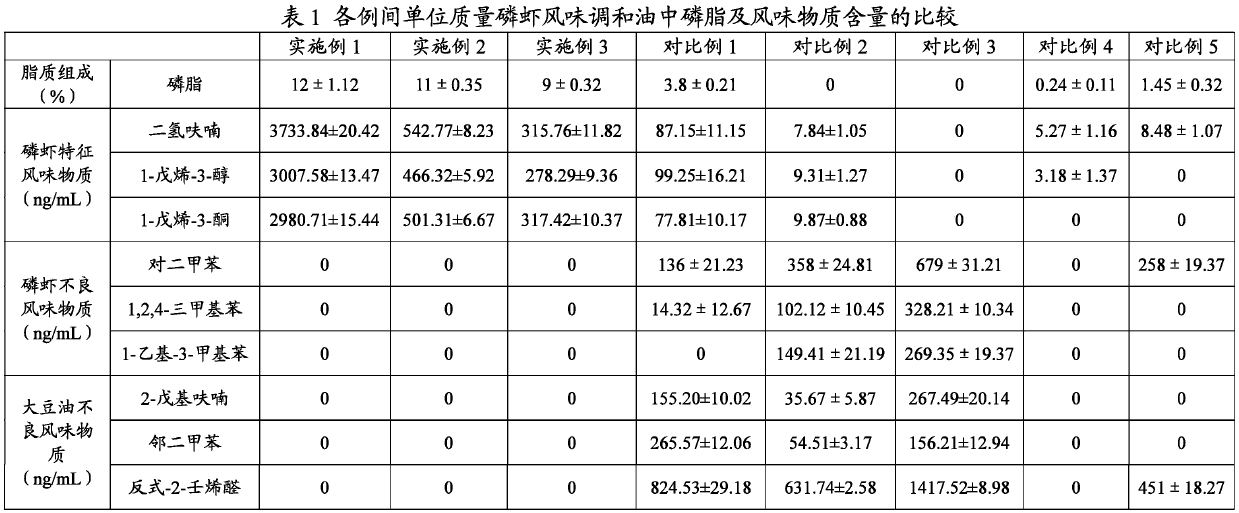

Examples

Embodiment 1

[0035] A preparation method of krill flavor vegetable blend oil rich in phospholipids, comprising the following steps:

[0036] S1: Take 2000g of Antarctic krill powder passed through a 200-mesh sieve and have a water content (weight%) of 10%, and mix it with 1000g soybean oil evenly to obtain a mixture;

[0037] S2: Using supercritical CO 2Extract the mixture obtained in step S1, the pressure of the extraction tank is 35.0MPa, and the temperature is 55°C; the pressure of the separation tank I is 15.0MPa, the temperature is 40°C, the pressure of the separation tank II is 9.0MPa, and the temperature is 35°C; the extraction time is 45 minutes after both the kettle and the separation kettle reached the predetermined pressure (that is, 45 minutes after the extraction kettle reached 35.0 MPa, the separation kettle I reached 15.0 MPa, and the separation kettle II reached 9.0 MPa), the product obtained from the separation kettle I was a krill-flavored vegetable blend oil.

[0038] T...

Embodiment 2

[0040] A preparation method of a plant blend oil rich in phospholipids, comprising the following steps:

[0041] S1: Take 1000g of Antarctic krill powder sieved through a 200-mesh sieve and have a water content (weight) of 8%, and mix it with 300g soybean oil evenly to obtain a mixture;

[0042] S2: Using supercritical CO 2 Extract the mixture obtained in step S1, the pressure of the extraction tank is 30MPa, and the temperature is 50°C; the pressure of the separation tank I is 10.0MPa, the temperature is 45°C, the pressure of the separation tank II is 6.0MPa, and the temperature is 40°C; the extraction time is 70min after the separation kettle reaches the predetermined pressure, the product obtained in the separation kettle 1 is krill flavor vegetable blend oil.

[0043] The krill-flavored plant blend oil obtained in this example is light yellow in color, clear and transparent, has a certain content of phospholipids, and contains krill characteristics such as dihydrofuran, 1...

Embodiment 3

[0045] A preparation method of krill flavor vegetable blend oil rich in phospholipids, comprising the following steps:

[0046] S1: Take 500 g of Antarctic krill powder passed through a 300-mesh sieve and having a water content (weight %) of 5%, and mix it with 100 g of soybean oil evenly to obtain a mixture;

[0047] S2: Using supercritical CO 2 Extract the mixture obtained in step S1, the pressure of the extraction tank is 25MPa, and the temperature is 45°C; the pressure of the separation tank I is 9.0MPa, the temperature is 50°C, the pressure of the separation tank II is 4.0MPa, and the temperature is 40°C; the extraction time is 120 minutes after the separation kettle reached the predetermined pressure, the product obtained in the separation kettle 1 was krill flavor vegetable blend oil.

[0048] The krill-flavored plant blend oil obtained in this example is light yellow in color, clear and transparent, has a certain content of phospholipids, and contains krill characteri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com