Processing method for improving quality of capsanthin

A technology of capsanthin and a processing method, which is applied in the field of preparation of natural pigments, can solve the problems of excessive phospholipid content and affect the color and luster of capsanthin, and achieves the effects of low phospholipid content, repeated utilization and quality improvement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

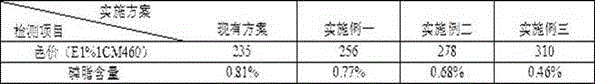

Embodiment 1

[0020] Dry red chili peppers, crush them and make chili granules, weigh 500g of chili granules and place them in a 5000ml round bottom flask, add 2000ml rapeseed oil to obtain mixed oil, extract at 40°C for 30min, then mix the mixed oil Sedimentation and filtration to obtain the filtrate and filter residue, and then use the filter residue as raw material, add rapeseed oil to repeat the above extraction process, dissolve the particles with rapeseed oil at 40°C to obtain a mixed oil, settle and filter the mixed oil to obtain the filtrate and filter residue, and then filter the residue As a raw material, repeat the above extraction process twice with rapeseed oil, blend the filtrate obtained from each extraction process, then put the filtrate into a distillation tank, and evaporate the solvent once at -0.05MPa, 60°C, and then Under the conditions of -0.08MPa and 35°C, the solvent was evaporated twice to obtain capsicum oleoresin, and the residue was removed from capsicum oleoresin...

Embodiment 2

[0022]Dry the red chili peppers, crush them and make chili granules, weigh 50kg of chili granules and place them in a 500L reactor, add 200L rapeseed oil to obtain a mixed oil, extract at 50°C for 30min, and then settle the mixed oil Filter to obtain filtrate and filter residue, then use filter residue as raw material, add rapeseed oil to repeat the above extraction process, dissolve particles with rapeseed oil at 50 °C to obtain mixed oil, settle and filter the mixed oil to obtain filtrate and filter residue, and then use filter residue as Raw materials, together with rapeseed oil, repeat the above extraction process twice, blend the filtrate obtained from each extraction process together, then put the filtrate into a distillation tank, evaporate the solvent once at -0.04MPa, 65°C, and then - Under the conditions of 0.07MPa and 45°C, the solvent was evaporated twice to obtain capsicum oleoresin, and the residue was removed from capsicum oleoresin at 46°C and 0.095MPa for 2.5 h...

Embodiment 3

[0024] Dry the red chili peppers, crush them and make chili granules, weigh 50kg of chili granules and place them in a 500L reactor, add 200L rapeseed oil to obtain a mixed oil, extract at 50°C for 30min, and then settle the mixed oil Filtrate to obtain filtrate and filter residue, then use filter residue as raw material, add rapeseed oil to repeat the above extraction process, dissolve particles with rapeseed oil at 45°C to obtain mixed oil, settle and filter the mixed oil to obtain filtrate and filter residue, and then use filter residue as Raw materials, together with rapeseed oil, repeat the above extraction process twice, blend the filtrate obtained from each extraction process together, then put the filtrate into a distillation tank, evaporate the solvent once at -0.045MPa, 62°C, and then in - Under the conditions of 0.075MPa and 42°C, the solvent was evaporated twice to obtain capsicum oleoresin, and the residue was removed from capsicum oleoresin at 50°C and 0.095MPa fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| color price | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com