Washing cleaning device for sweet potato storage

A cleaning device and water washing technology, applied in applications, food processing, food science, etc., can solve problems such as poor effect, uneven distribution, and difficult removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

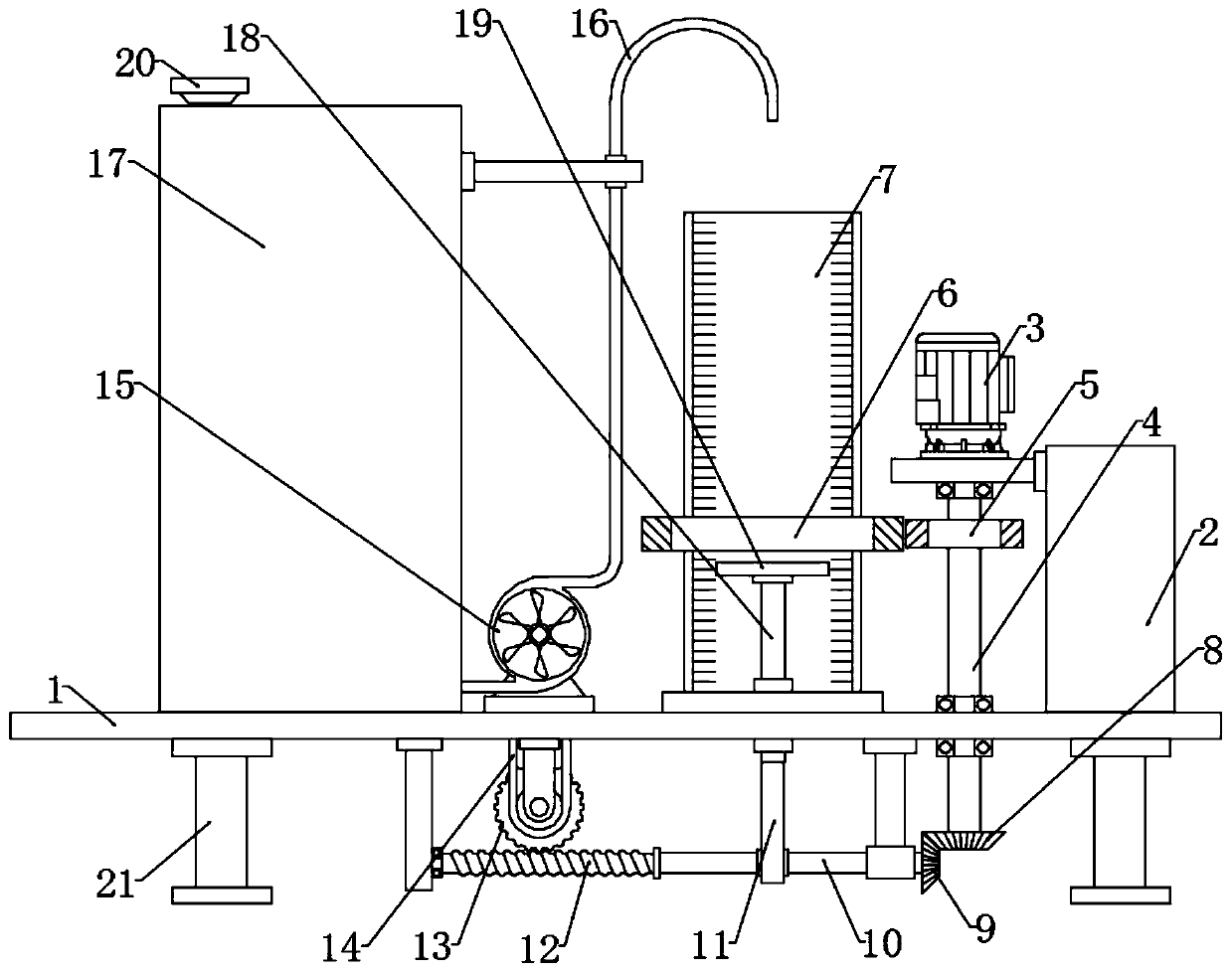

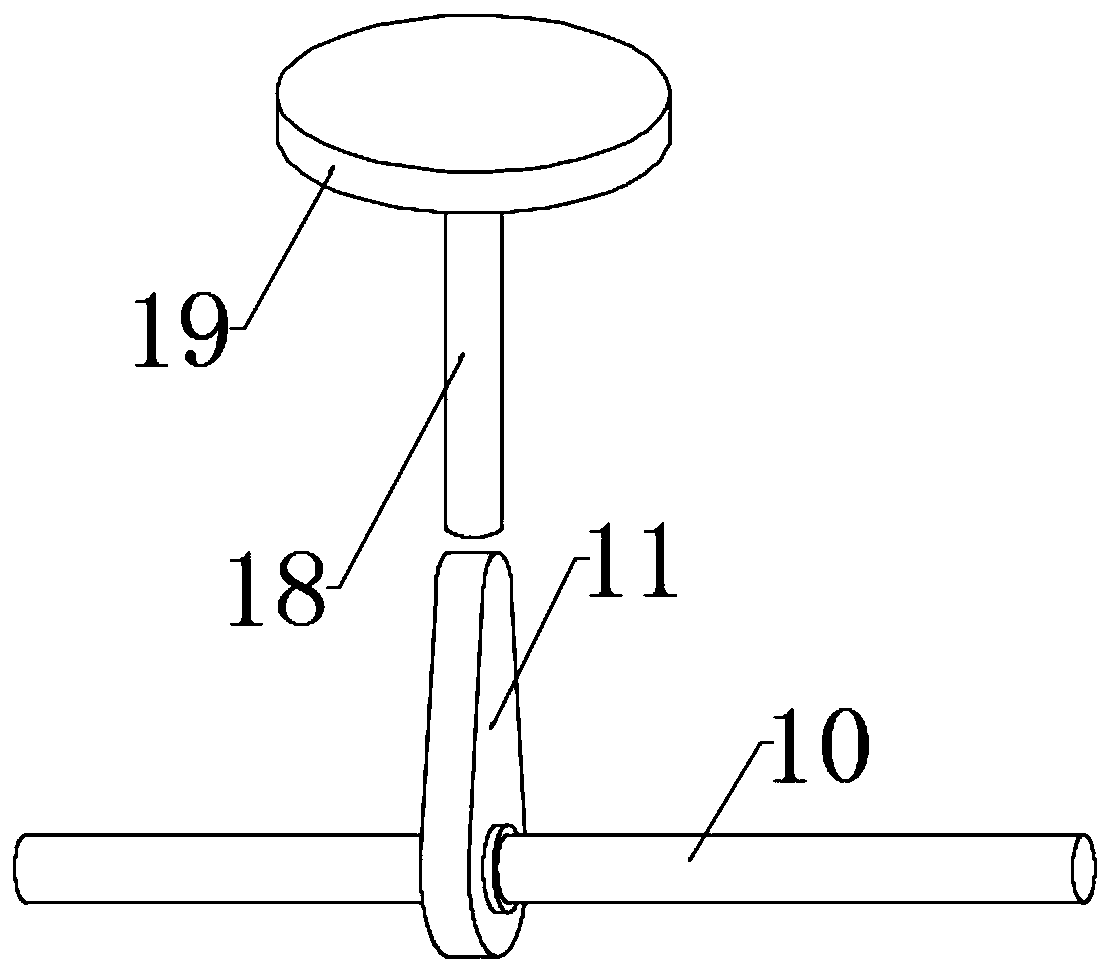

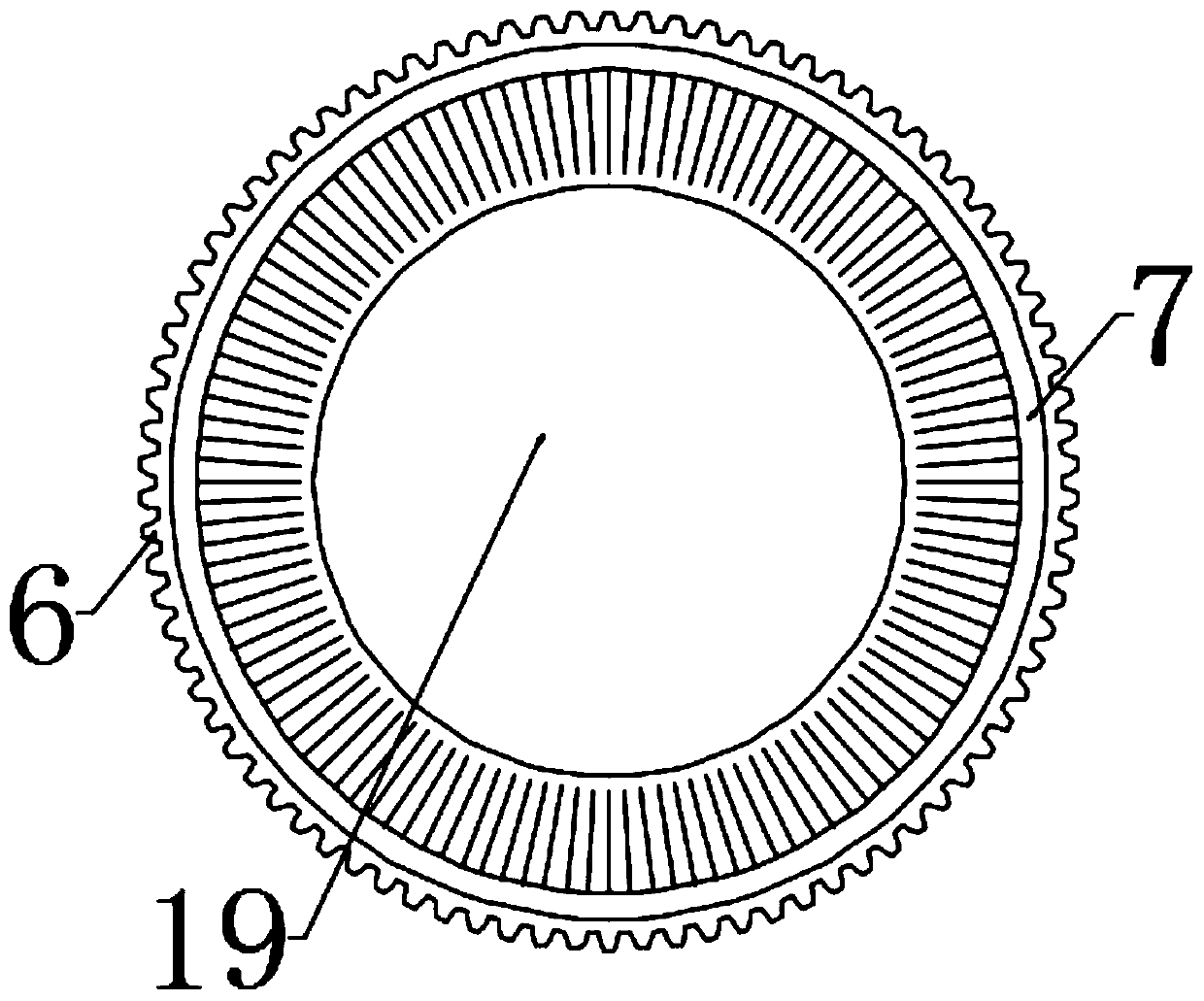

[0021] see Figure 1~3 , in the embodiment of the present invention, a washing and cleaning device for sweet potato storage includes a workbench 1, a cleaning bucket 7 rotatably arranged on the workbench 1, and a jacking mechanism, wherein one side of the workbench 1 is fixedly installed with a The electric box 2 and the upper flange of the distribution box 2 are equipped with a motor 3 electrically connected to it, the output end of the motor 3 is connected to the driving shaft 4 in rotation, and the upper part of the driving shaft 4 is fixedly connected with a small gear 5 meshing with the large gear 6, The large gear 6 is fixed on the outer wall of the cleaning bucket 7. It should be noted that a plurality of bristles are uniformly arranged on the inner wall of the cleaning bucket 7, and the harvested sweet potatoes are put into the cleaning bucket 7 and filled with clean water, and the electric motor 3 is energized to work. Driving shaft 4 and pinion 5 rotate, and pinion 5...

Embodiment 2

[0024] In order to better replace the water in the cleaning bucket 7, in another embodiment of the present invention, a water washing and cleaning device for sweet potato storage also includes a water supply mechanism, and the water supply mechanism includes a The water pump 15, the water tank 17 installed on the side of the workbench 1 opposite to the distribution box 2, and the worm 12 fixedly connected to the driven shaft 10 and rotatably arranged under the workbench 1, wherein the upper part of the worm 12 is engaged and rotatably connected under the workbench 1 The worm wheel 13, the side of the worm wheel 13 is connected to the impeller arranged in the water pump 15 through the transmission member 14, the driven shaft 10 drives the worm 12 to rotate, and the worm 12 drives the worm wheel 13 to rotate, and the worm wheel 13 uses the transmission member 14 to drive the water pump 15 The impeller in the pump turns to pump water;

[0025] Further, the input end of the water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com