Water-gas separating system

A water-gas separation and airflow technology, which is applied in separation methods, dispersed particle separation, gas treatment, etc., can solve the problems of the impact of gas transport efficiency, high construction cost and maintenance cost, and achieve the effect of low equipment cost and easy maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

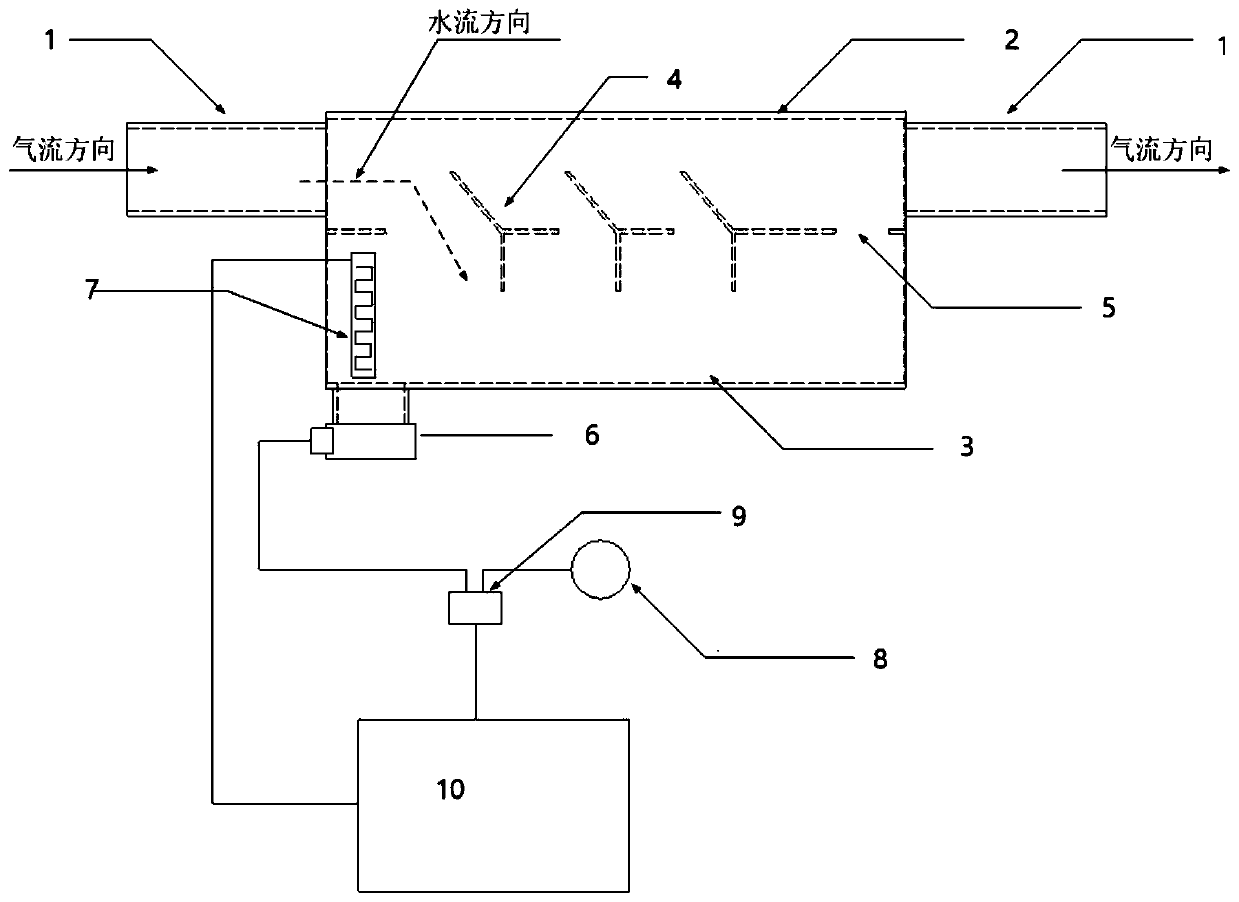

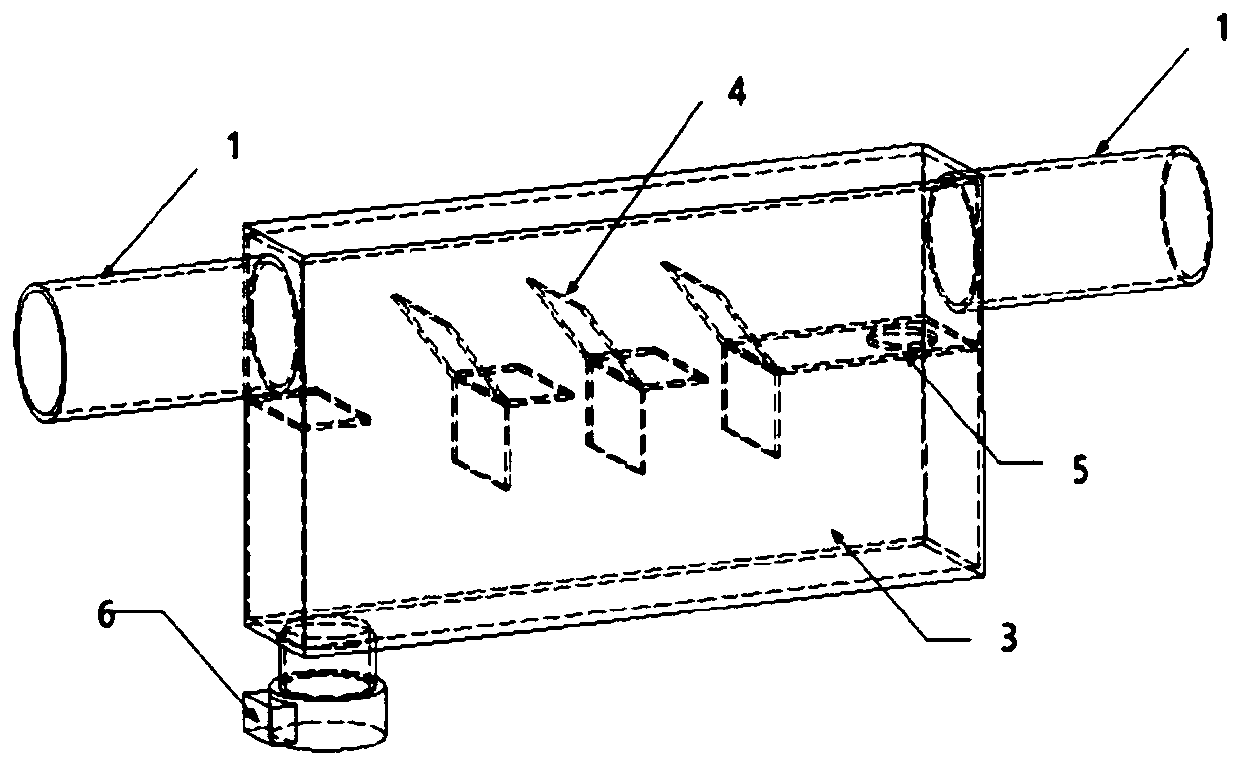

[0018] A specific embodiment of the present invention is: the water-gas separation system includes two parts, a mechanical structure and an electric control system. The mechanical part of the water-gas separation system is mainly the box of the water-gas separator. The water-gas separator box includes pipeline parts 2, water storage tank 3, water baffle 4, air guide hole 5 and other structures; the electric control system of the water-gas separation system includes a water level sensor 7, a single-chip microcomputer 10, a relay 9, and a power supply of the drainage pump 8. Drainage pump6.

[0019] Such as figure 1 As shown, the principle of the water-gas separation system is mainly that when the air flow (entrained water flow) flows through the water-gas separator through the pipeline, due to the high specificity of water, it flows through the lower part of the pipeline and passes through the baffle plate 4 to block the flow into the storage tank. The water tank 3, while the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com