Modularized propulsion service system based on hybrid mode propulsion

A service system and mixed-mode technology, applied in the field of modular propulsion service systems, can solve the problems of high price, affecting satellite performance, and high cost, and achieve the effects of efficient utilization, improved control accuracy, and improved load-to-dry ratio.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention is described in further detail below in conjunction with accompanying drawing:

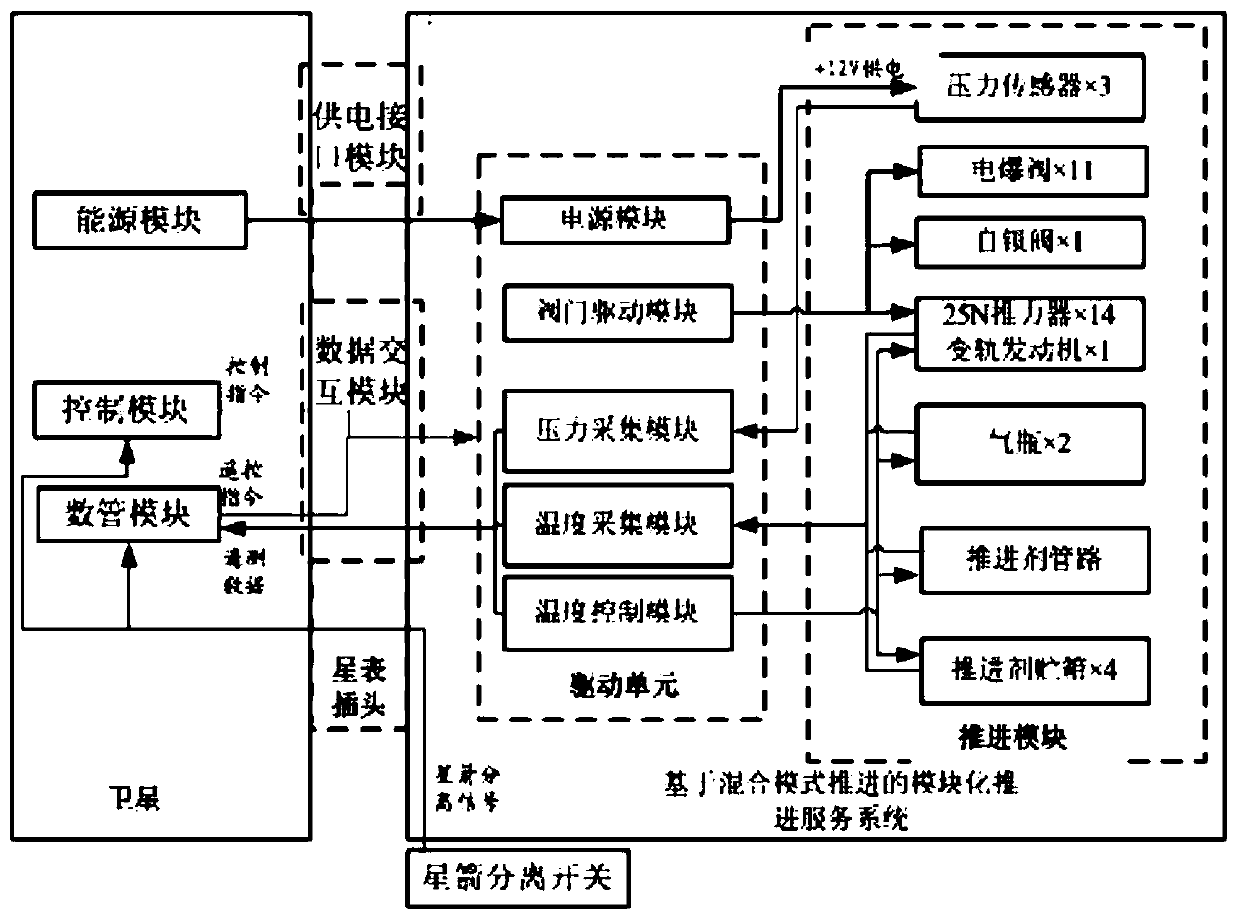

[0030] A modular propulsion service system based on hybrid mode propulsion, including a satellite platform and a modular propulsion service system, such as figure 1 As shown, the satellite platform includes an energy module, a control module, and a data management module, and the modular propulsion service system includes a structural module, a propulsion module, a drive unit, a passive end of a power supply interface module, and a passive end of a data interaction module.

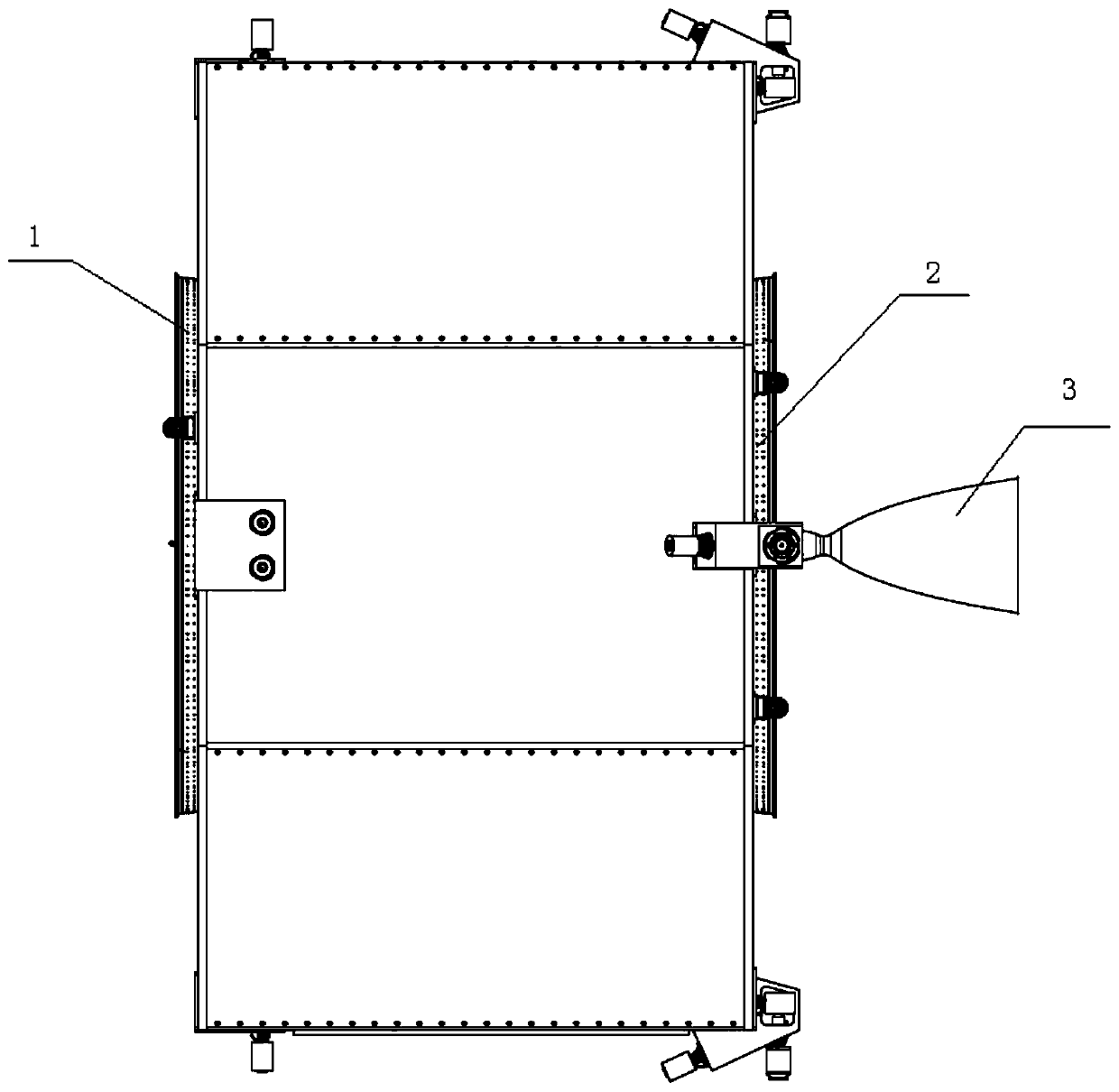

[0031] The bottom of the satellite platform is provided with the first docking frame, the active end of the power supply interface module and the active end of the data interaction module,

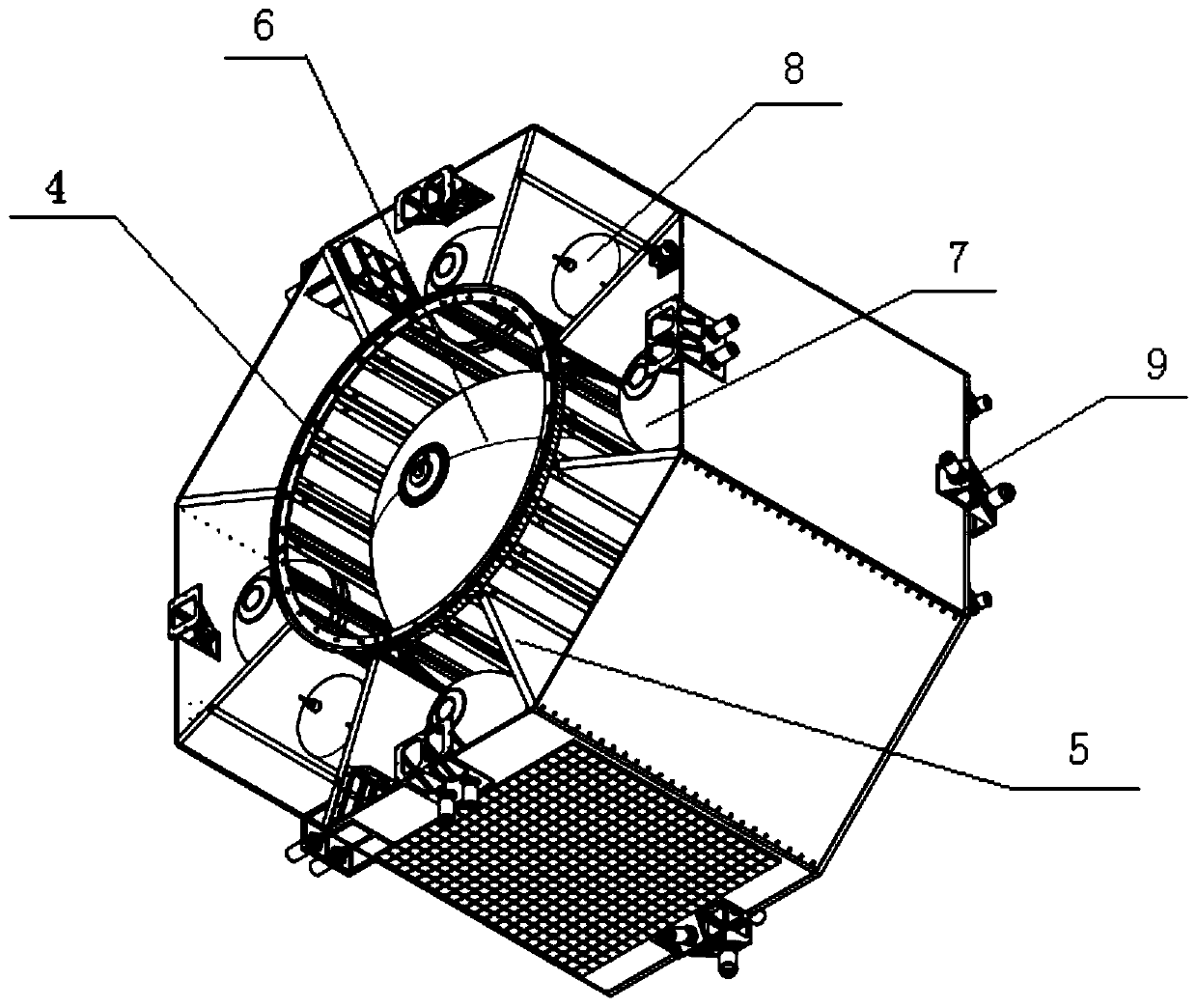

[0032] like figure 2 As shown, the top of the structural module of the propulsion service system is provided with a second docking frame 1, and the bottom is provided with a third docking frame 2, and the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com