Gel particle plugging agent and preparation method and application thereof

A gel particle and plugging agent technology, which is applied in the field of drilling fluid plugging, can solve the problems of poor high temperature resistance and low plugging effect of lost channels, and achieve good plugging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

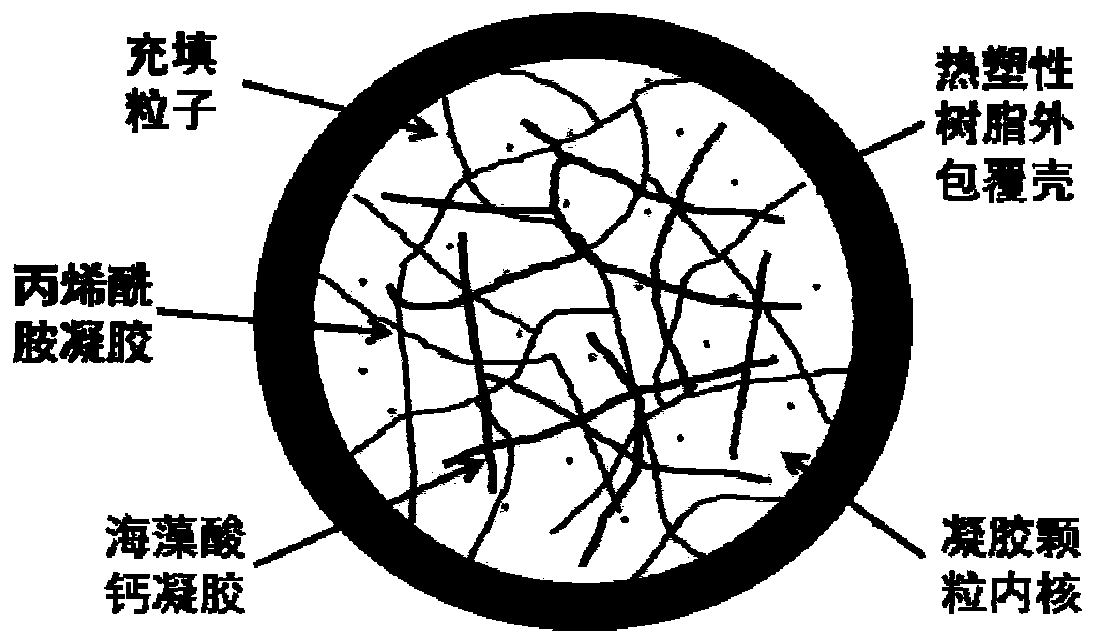

[0073] According to the present invention, the preparation method of described gel particle comprises the following steps:

[0074] (1) stirring the lipophilic emulsifier, the hydrophilic emulsifier and the oil phase solvent evenly to obtain solution a;

[0075] (2) adding the non-ionic monomer and the cross-linking agent into the deionized water, stirring until completely dissolved, to obtain the mixed solution b;

[0076] (3) Add alginate into the mixed solution b, stir until completely dissolved, and obtain the mixed solution c;

[0077] (4) Add the filling particles into the mixed liquid c, add a dispersing aid, stir until completely dissolved, and obtain the mixed liquid d;

[0078] (5) Slowly add the mixed solution d to the solution a, and stir to obtain the mixed solution e;

[0079] (6) The initiator is added into deionized water, and stirred until completely dissolved to obtain solution f;

[0080] (7) solution f is added dropwise in mixed solution e, after carryin...

preparation example 1

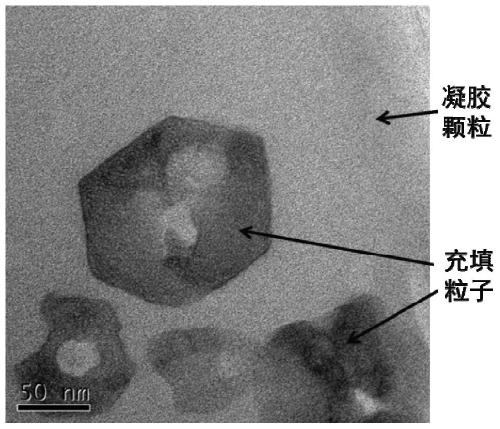

[0124] Preparation of gel particles

[0125] (1) stirring the lipophilic emulsifier, the hydrophilic emulsifier and the oil phase solvent evenly to obtain solution a;

[0126] (2) adding the non-ionic monomer and the cross-linking agent into the deionized water, stirring until completely dissolved, to obtain the mixed solution b;

[0127] (3) Add alginate into the mixed solution b, stir until completely dissolved, and obtain the mixed solution c;

[0128] (4) Add the filling particles into the mixed liquid c, add a dispersing aid, stir until completely dissolved, and obtain the mixed liquid d;

[0129] (5) Slowly add the mixed solution d to the solution a, and stir to obtain the mixed solution e;

[0130] (6) The initiator is added into deionized water, and stirred until completely dissolved to obtain solution f;

[0131] (7) solution f is added dropwise in mixed solution e, after carrying out first reaction, carry out stand still for the first time, obtain microemulsion g;...

preparation example 2

[0135] Preparation of gel particle plugging agent

[0136] (a) heating the thermoplastic resin until it is completely melted to obtain a molten thermoplastic resin;

[0137] (b) stirring and mixing the gel particles and the melted thermoplastic resin evenly, and then performing cooling treatment to obtain a solid phase mixture;

[0138] (c) Grinding the solid phase mixture to make a gel particle plugging agent.

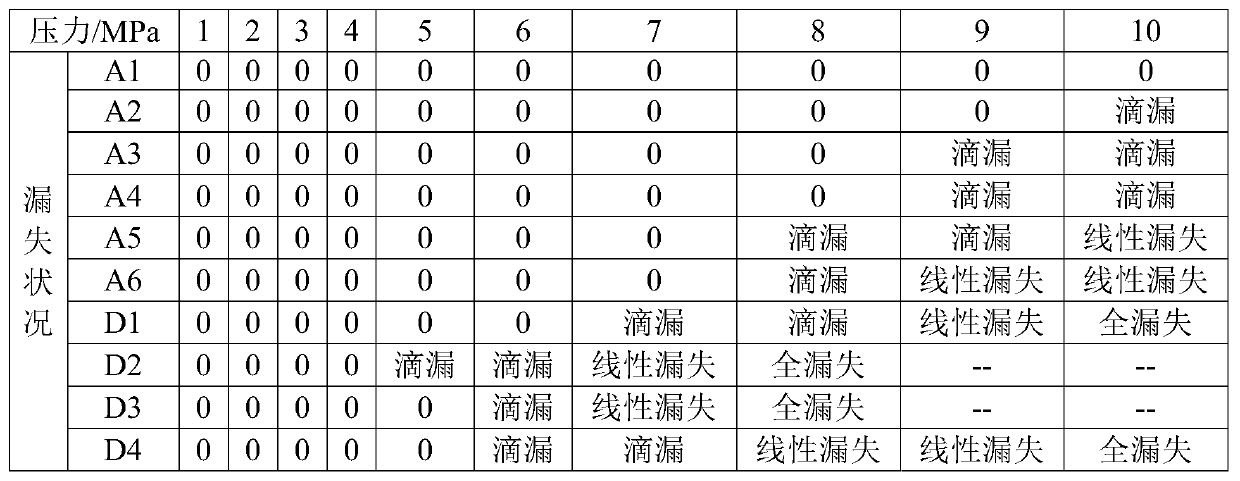

[0139] In order to ensure that the basic conditions of the examples and comparative examples are consistent, in the following examples and comparative examples, the particle size of the gel particle plugging agent with a "core / shell" structure is selected to be 500 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com