A long-span composite structure floor

A combined structure and large-span technology, which is applied to floors, building components, building structures, etc., can solve the problems of limited structural strength of prefabricated floor slabs, high density of concrete columns, and large number of concrete columns, and achieve excellent seismic performance, The effect of improving structural strength and improving toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

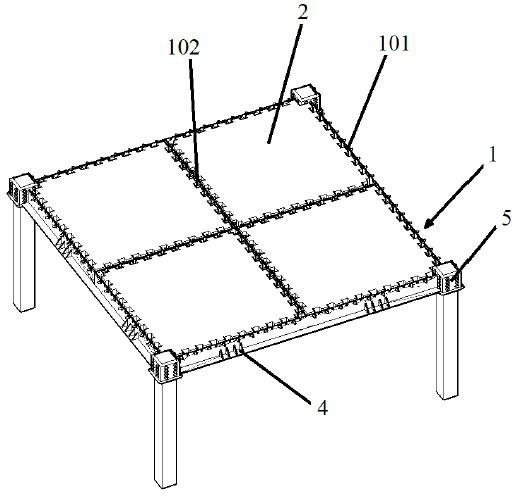

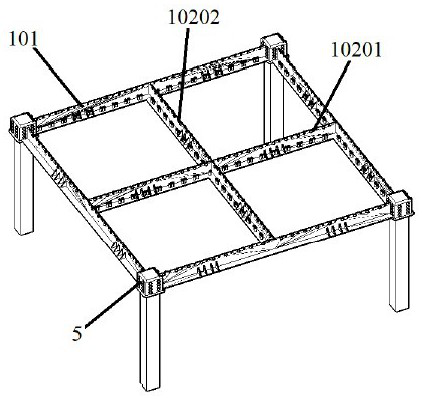

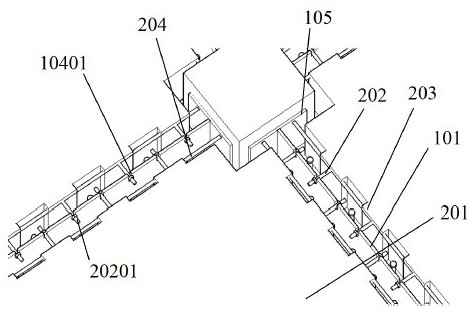

[0090] A long-span composite structure floor includes: a composite steel beam structure 1 and a prefabricated floor slab 2 . The composite steel beam structure 1 includes: an outer frame steel beam 101 and an inner cross steel beam 102 . The outer frame steel beam 101 is connected with the concrete column. The inner cross steel beam 102 is erected on the outer frame steel beam 101 and located inside the rectangular frame formed by the outer frame steel beam 101 . The outer frame steel beam 101 and the inner cross steel beam 102 form a "Tian"-shaped structure. The prefabricated floor slab 2 is arranged in the box formed by the outer frame steel beam 101 and the inner cross steel beam 102 .

Embodiment 2

[0092] Embodiment 1 is repeated, except that the large-span composite structure floor further includes: a guiding and clamping mechanism 3 . The guiding and clamping mechanism 3 includes: a supporting arm 301 , a clamping arm 302 , and a rotating shaft 303 . The supporting arm 301 is fixedly connected with the clamping arm 302 . The rotating shaft 303 is disposed at the joint of the supporting arm 301 and the clamping arm 302 . The rotating shaft 303 is installed on the contact surface between the prefabricated floor slab 2 and the composite steel beam structure 1 . The supporting arm 301 is located at the bottom of the prefabricated floor slab 2 . The clamping arm 302 is in contact with the edge side of the prefabricated floor slab 2 .

Embodiment 3

[0094] Embodiment 1 is repeated, except that the large-span composite structure floor further includes: an installation guide structure 4 . The installation guide structure 4 is a guide rib. The installation guide structure 4 is arranged on the contact surface between the prefabricated floor slab 2 and the composite steel beam structure 1 . The installation guide structure 4 is provided with a guide slope 401 . The bottom of the guide slope 401 is in contact with the prefabricated floor slab 2 . The guiding slope 401 is a plane, or the guiding slope 401 is a curved surface.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com